Nov . 27, 2024 23:41 Back to list

Advanced Digital Diaphragm Pressure Gauge for Precise Pressure Measurement and Control

Understanding Digital Diaphragm Pressure Gauges Features, Benefits, and Applications

In numerous industrial and commercial applications, precise measurement of pressure is crucial for ensuring safety, efficiency, and reliability. Among the various types of pressure measuring instruments, digital diaphragm pressure gauges have gained significant traction due to their accuracy and user-friendly features. This article explores the fundamentals of digital diaphragm pressure gauges, their advantages, and the diverse applications in which they are utilized.

What is a Digital Diaphragm Pressure Gauge?

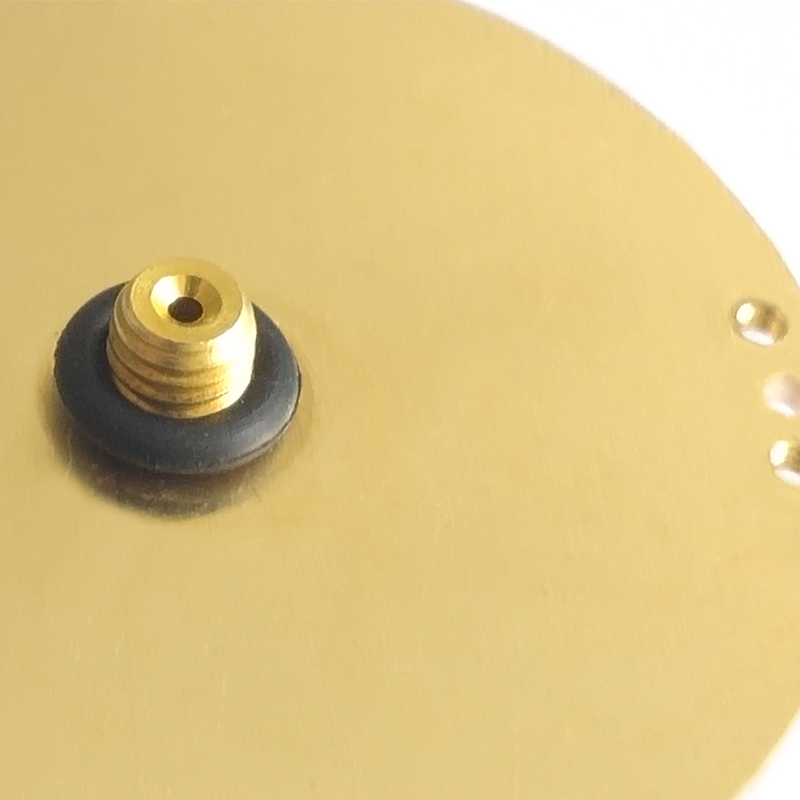

A digital diaphragm pressure gauge is an advanced instrument designed to measure the pressure of gases and liquids. It utilizes a diaphragm, which is a flexible membrane that responds to pressure changes. When pressure is applied, the diaphragm deflects, causing a change in its shape. This deformation is then translated into an electrical signal, which is converted into a digital readout, providing users with a precise measurement of pressure.

Digital diaphragm pressure gauges are equipped with advanced electronics that enhance their functionality. These devices often feature LCD screens for clear readability, various output signals (like 4-20 mA), and options for data logging and remote monitoring.

Key Features of Digital Diaphragm Pressure Gauges

1. High Accuracy and Precision Digital diaphragm gauges are known for their high level of precision, making them ideal for applications where every second counts.

2. Wide Measurement Range These gauges can measure a broad spectrum of pressures, from vacuum to high pressure, which makes them versatile across different industrial sectors.

4. Easy-to-Read Displays The digital readouts make it easy for operators to read pressure levels at a glance, minimizing errors associated with analog gauges.

5. Advanced Features Many models come with advanced functionalities including programmable alarms for pressure thresholds, data logging capabilities, and even connectivity options for smart monitoring systems.

digital diaphragm pressure gauge product

Benefits of Using Digital Diaphragm Pressure Gauges

1. Improved Safety With high accuracy in measuring pressure, these gauges play a significant role in preventing accidents and maintaining safe operating conditions in various processes, particularly in industries like oil and gas or chemical manufacturing.

2. Cost Efficiency The reliability and long service life of digital diaphragm gauges can lead to significant cost savings over time, reducing the need for frequent replacements and repairs.

3. User-Friendly The intuitive designs and functions of digital gauges, such as easy calibration and setup, enhance the user experience, allowing for quicker training and adaptation.

4. Data Analysis Capability With features like data logging and connectivity, these gauges enable better tracking and analysis of pressure trends over time, which is invaluable for process optimization.

Applications of Digital Diaphragm Pressure Gauges

Digital diaphragm pressure gauges are used in a wide range of applications across various industries

- Oil and Gas Industry Monitoring pressure in pipelines, tanks, and refining processes to ensure safety and compliance. - Chemical Processing Ensuring accurate pressure readings in reactors and storage tanks to prevent hazardous situations. - Automotive Used in testing various systems including fuel pressure, tire pressure, and air pressure in HVAC systems. - HVAC Systems Monitoring pressures in heating, ventilation, and air conditioning systems for efficiency and optimal performance. - Pharmaceuticals Critical in maintaining pressure in processes that require sterile environments, ensuring product safety and compliance with regulations.

Conclusion

Digital diaphragm pressure gauges represent a significant advancement in the field of pressure measurement technology. Their combination of accuracy, durability, and advanced features makes them an invaluable tool across various industries. As businesses increasingly prioritize safety, efficiency, and data-driven decision-making, the demand for such sophisticated instruments is likely to continue growing. Understanding and utilizing these gauges effectively can lead to enhanced operational performance and reliability in any pressure-related application.

-

Precision Differential Pressure Gauge Assembly Reliable & Customizable Solutions

NewsMay.29,2025

-

WIKA Sanitary Diaphragm Pressure Gauge High Precision & Durability

NewsMay.29,2025

-

HD Fire Pressure Gauges High Accuracy & Durable Solutions

NewsMay.28,2025

-

Custom Singles Capsule Systems Top Exporters & Factories

NewsMay.28,2025

-

Piston-Style Differential Pressure Gauges Precision & Durability

NewsMay.28,2025

-

WIKA Differential Pressure Gauge 700.04 High-Accuracy Industrial Measurement

NewsMay.28,2025