Déc . 05, 2024 15:37 Back to list

high precision pressure gauge factories

High Precision Pressure Gauge Factories An Overview

In the world of industrial applications, the importance of precise measurements cannot be overstated. High precision pressure gauges are crucial instruments used across various sectors, including oil and gas, pharmaceuticals, automotive, and food and beverage industries. These devices are designed to measure the pressure of liquids and gases with exceptional accuracy, making them indispensable for ensuring safety and efficiency in operations. This article delves into the essential aspects of high precision pressure gauge factories, exploring their significance, manufacturing processes, and the future of this industry.

The Significance of High Precision Pressure Gauges

High precision pressure gauges are vital for maintaining quality control in production processes. In industries where pressure differentials can influence product quality or safety, such as in chemical processing or aerospace applications, precise measurements are imperative. Even slight deviations in pressure readings can lead to significant operational issues, including equipment failure, product contamination, or even catastrophic accidents.

Moreover, as industries evolve, the demand for more sophisticated measuring tools continues to grow. High precision gauges not only enhance safety but also improve overall productivity by ensuring that systems operate within their designated parameters. These gauges often come equipped with advanced features such as digital displays, data logging, and connectivity options, allowing operators to monitor and analyze real-time data effectively.

Manufacturing Processes in Pressure Gauge Factories

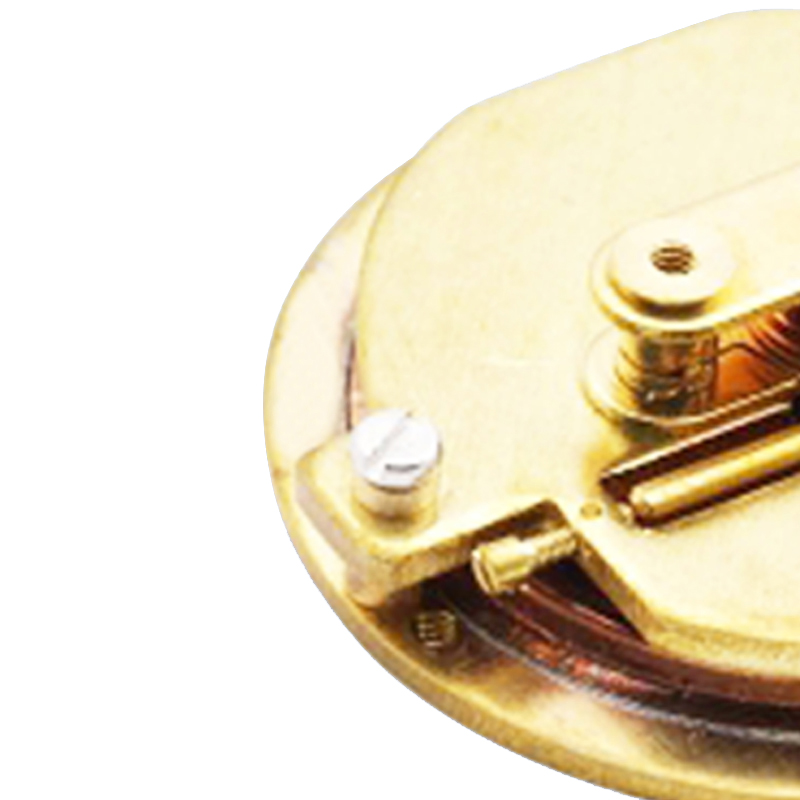

The manufacturing of high precision pressure gauges is a complex process that involves several stages. Factories begin by sourcing high-quality raw materials, such as stainless steel, brass, and specialized polymers, that can withstand harsh environments and corrosive substances. The choice of materials is crucial in ensuring the durability and accuracy of the gauges.

high precision pressure gauge factories

Once the materials are procured, the next step involves precision machining. This encompasses cutting, shaping, and assembling the components to create the gauge body and internal mechanisms. CNC (Computer Numerical Control) machining is often employed to achieve the high tolerances required for accurate pressure measurement. Following machining, components undergo rigorous testing to ensure they meet quality standards.

After assembly, calibration is a critical step. Each pressure gauge must be calibrated against known pressure standards to ensure accuracy. Calibration involves comparing the gauge readings with reliable reference points and making necessary adjustments to eliminate discrepancies. Factories invest in advanced calibration equipment to guarantee their products meet industry-specific regulations and standards.

The Future of High Precision Pressure Gauge Manufacturing

As technology continues to advance, the landscape of high precision pressure gauge manufacturing is evolving. The integration of IoT (Internet of Things) technology has begun to influence these gauges, making them more intelligent and capable of continuous monitoring and data transmission. For instance, smart pressure gauges can transmit data to centralized systems, allowing for real-time analysis and predictive maintenance.

Furthermore, environmental considerations are becoming increasingly important in manufacturing processes. Many factories are adopting sustainable practices, focusing on reducing waste and energy consumption. The development of environmentally friendly materials and manufacturing methods is anticipated to lead to a new generation of pressure gauges that are not only precise but also eco-conscious.

In conclusion, high precision pressure gauge factories play a pivotal role in various industries by providing essential tools for accurate pressure measurement. With ongoing advancements in technology and a growing emphasis on sustainability, the future of this industry looks promising. As industries increasingly rely on precise data to drive innovation and safety, the demand for high quality and precision in pressure measurement will undoubtedly continue to rise. This emerging focus on technology, quality, and environmental responsibility will define the next chapter in the evolution of pressure gauge manufacturing.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025