Fév . 16, 2025 15:10 Back to list

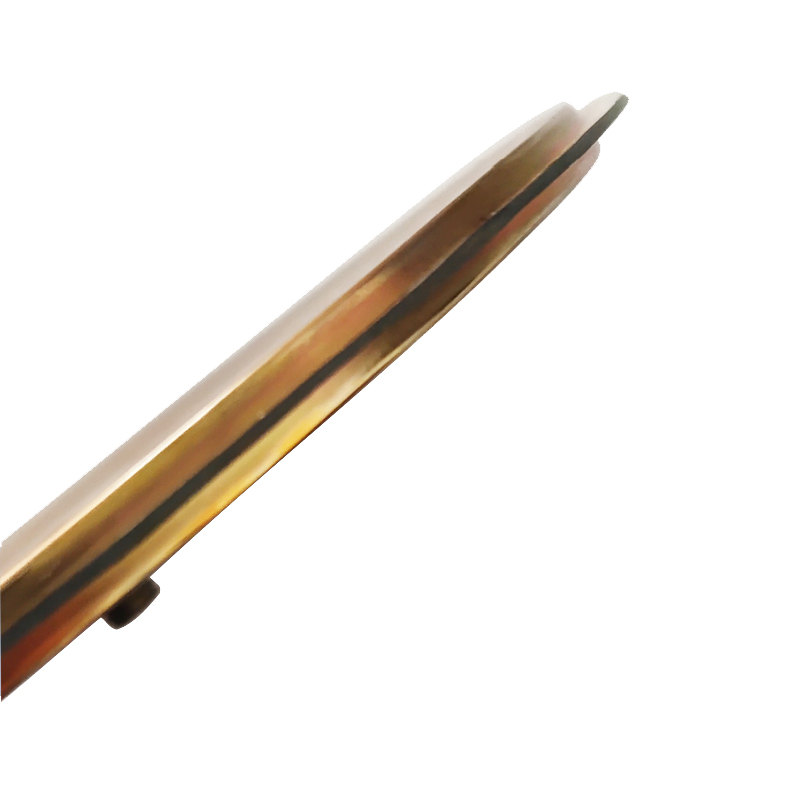

high quality flange diaphragm seal pressure gauge

High quality flange diaphragm seal pressure gauges are indispensable tools in industrial applications that deal with the monitoring and regulation of pressure in various systems. These devices not only ensure accuracy and reliability but also enhance the lifespan of machinery by averting any undue stress caused by pressure fluctuates. The expertise in the manufacture and application of these gauges underscores their importance in fields such as chemical processing, oil refineries, power generation, and pharmaceuticals.

Choosing the right flange diaphragm seal comes down to trustworthiness, which is built on the reputation of manufacturers who adhere to international standards such as ISO 9001 and industry-specific standards like ASME. Certification ensures that each gauge is built to meet stringent quality criteria. An authoritative manufacturer will also offer extensive support, including installation guidance, maintenance tips, and calibration services, guaranteeing that the gauges continue to operate flawlessly throughout their service life. Moreover, investing in high-quality diaphragm seal pressure gauges demonstrates a commitment to operational excellence. Industries relying on these devices benefit from reduced downtime and improved safety. By preventing pressure discrepancies that could lead to hardware failure, these gauges play a critical role in safeguarding against potentially hazardous scenarios. Incorporating digital advancements further elevates the capability of these gauges. Modern high-quality flange diaphragm seal pressure gauges can be integrated with digital displays or data transmission systems for remote monitoring. This feature is particularly valuable in monitoring pressure in real-time, allowing for instantaneous decision-making. The integration of IoT solutions into these pressure gauges also facilitates predictive maintenance, alerting operators of potential failures before they occur, thus enhancing the reliability of entire systems. Installation and maintenance are crucial aspects that impact the pressure gauge performance over its lifecycle. Proper installation by skilled technicians, using correct torque and alignment, ensures that the seal remains intact under varying operational pressures. Regular maintenance to inspect for any wear or anomalies reinforces the durability and precision of the gauge. Trusted suppliers provide comprehensive manuals and resources to aid in proper installation and maintenance, alongside customer support to address any complexities encountered during use. In summary, a high-quality flange diaphragm seal pressure gauge represents the pinnacle of precision engineering and expert manufacturing. Through robust material selection, adherence to international standards, and leveraging digital technologies, these instruments offer unparalleled accuracy and reliability in industrial pressure monitoring. Trust in these gauges is backed by comprehensive support systems and a proven track record of safety and efficiency, making them the preferred choice for industries where precision and dependability are non-negotiable.

Choosing the right flange diaphragm seal comes down to trustworthiness, which is built on the reputation of manufacturers who adhere to international standards such as ISO 9001 and industry-specific standards like ASME. Certification ensures that each gauge is built to meet stringent quality criteria. An authoritative manufacturer will also offer extensive support, including installation guidance, maintenance tips, and calibration services, guaranteeing that the gauges continue to operate flawlessly throughout their service life. Moreover, investing in high-quality diaphragm seal pressure gauges demonstrates a commitment to operational excellence. Industries relying on these devices benefit from reduced downtime and improved safety. By preventing pressure discrepancies that could lead to hardware failure, these gauges play a critical role in safeguarding against potentially hazardous scenarios. Incorporating digital advancements further elevates the capability of these gauges. Modern high-quality flange diaphragm seal pressure gauges can be integrated with digital displays or data transmission systems for remote monitoring. This feature is particularly valuable in monitoring pressure in real-time, allowing for instantaneous decision-making. The integration of IoT solutions into these pressure gauges also facilitates predictive maintenance, alerting operators of potential failures before they occur, thus enhancing the reliability of entire systems. Installation and maintenance are crucial aspects that impact the pressure gauge performance over its lifecycle. Proper installation by skilled technicians, using correct torque and alignment, ensures that the seal remains intact under varying operational pressures. Regular maintenance to inspect for any wear or anomalies reinforces the durability and precision of the gauge. Trusted suppliers provide comprehensive manuals and resources to aid in proper installation and maintenance, alongside customer support to address any complexities encountered during use. In summary, a high-quality flange diaphragm seal pressure gauge represents the pinnacle of precision engineering and expert manufacturing. Through robust material selection, adherence to international standards, and leveraging digital technologies, these instruments offer unparalleled accuracy and reliability in industrial pressure monitoring. Trust in these gauges is backed by comprehensive support systems and a proven track record of safety and efficiency, making them the preferred choice for industries where precision and dependability are non-negotiable.

Share

Latest news

-

Diaphragm Type Differential Pressure Gauges High-Accuracy & Durable Solutions

NewsMay.17,2025

-

Bellow Type Differential Pressure Gauge High Accuracy & Durable Design

NewsMay.17,2025

-

WIKA 700.04 Differential Pressure Gauge Precision Industrial Measurement

NewsMay.17,2025

-

Fire Extinguisher Pressure Gauge Manufacturers Reliable & Certified Suppliers

NewsMay.16,2025

-

Isolation Diaphragm Pressure Gauges High-Precision & Durable Solutions

NewsMay.16,2025

-

Premium Pressure Gauge Precision Instruments Reliable & Durable Solutions

NewsMay.16,2025