Sep . 29, 2024 00:53 Back to list

Understanding the Functionality of Differential Pressure Gauges in Industrial Applications

Understanding the JAH Differential Pressure Gauge A Comprehensive Overview

In industrial applications, monitoring pressure is crucial for ensuring optimal performance and safety. One of the essential tools used for this purpose is the differential pressure gauge. Among various types available, the JAH differential pressure gauge stands out due to its reliability and precision. This article delves into the functionality, application, and advantages of the JAH differential pressure gauge.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points in a system. Unlike standard gauges that measure absolute pressure, differential gauges provide insights into variations, which can be critical for certain processes. These measurements are essential in applications like HVAC systems, filtration monitoring, and fluid dynamics.

Overview of the JAH Differential Pressure Gauge

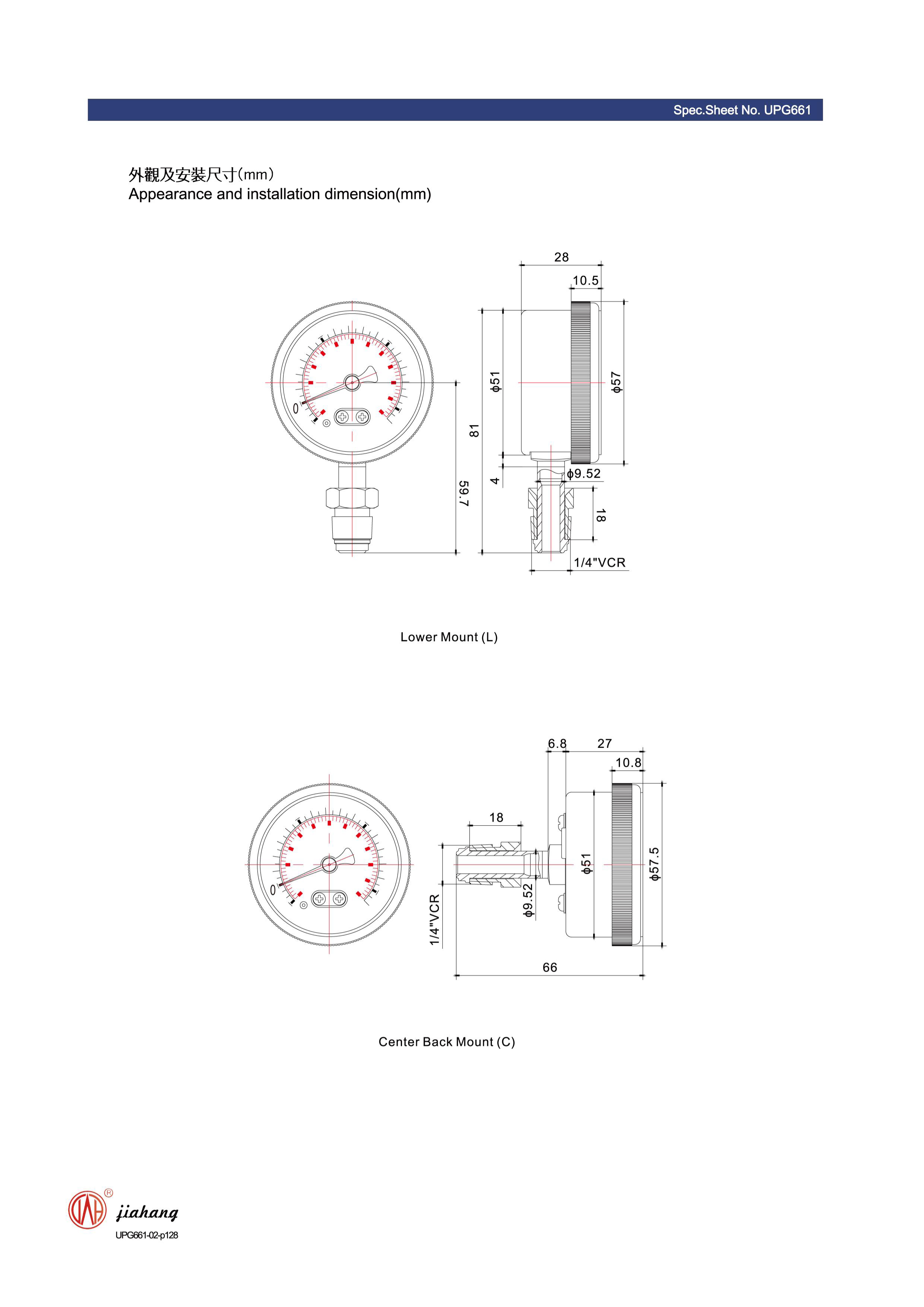

The JAH differential pressure gauge is designed with advanced technology that enhances its accuracy and durability. It typically features a robust construction with materials that can withstand harsh industrial environments, ensuring longevity. The gauge usually consists of two pressure ports, allowing it to measure the difference in pressure from two locations simultaneously.

One of the defining features of the JAH gauge is its intuitive design, making it easy to install and operate. Additionally, many models come with digital displays that provide clear readings, enhancing user experience and facilitating real-time monitoring.

Applications of the JAH Differential Pressure Gauge

The JAH differential pressure gauge has diverse applications across various industries

. Here are some notable uses1. HVAC Systems In heating, ventilation, and air conditioning systems, maintaining optimal airflow is crucial. The JAH gauge can monitor the pressure drop across filters or coils to ensure that the system operates efficiently. A significant pressure drop may indicate a blockage or need for maintenance.

2. Filtration Monitoring In industries such as pharmaceuticals and food production, filtration systems are integral for maintaining product quality. The JAH gauge helps monitor the differential pressure across filters to ensure they are functioning correctly, thereby preventing contamination.

jah differential pressure gauge p&

3. Fluid Dynamics In processes involving the flow of liquids and gases, understanding pressure differentials helps in optimizing performance. The JAH differential pressure gauge assists engineers in designing systems that operate within safe and efficient limits.

4. Hydraulic Systems For hydraulic machinery, maintaining the correct pressure differential is essential for operational safety and performance. The JAH gauge can provide critical data to prevent system failures.

Advantages of the JAH Differential Pressure Gauge

1. High Accuracy One of the primary benefits of the JAH gauge is its high level of accuracy. This precision ensures that users receive reliable readings, critical for making informed decisions in industrial processes.

2. Durability Constructed with robust materials, the JAH differential pressure gauge is designed to withstand harsh environmental conditions, reducing the need for frequent replacements.

3. Ease of Use The user-friendly interface and clear displays make the JAH gauge accessible for operators of all skill levels. This ease of use helps in reducing training time and potential errors in data interpretation.

4. Versatility The JAH differential pressure gauge can be used in various applications, making it a versatile tool for engineers and technicians in multiple industries. Its adaptability ensures that it can meet diverse operational needs.

5. Real-time Monitoring Many JAH gauge models offer real-time data, allowing operators to monitor system performance continuously. This feature is crucial for immediate decision-making and troubleshooting.

Conclusion

The JAH differential pressure gauge plays a vital role in various industrial applications by providing accurate and reliable measurements of pressure differentials. Its robust design, versatility, and ease of use make it an indispensable tool for professionals seeking to enhance system efficiency and safety. As industries continue to evolve and prioritize precision, the JAH differential pressure gauge will remain a significant player in optimizing operational performance across sectors.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025