Jan . 26, 2025 03:56 Back to list

oem differential pressure gauge price

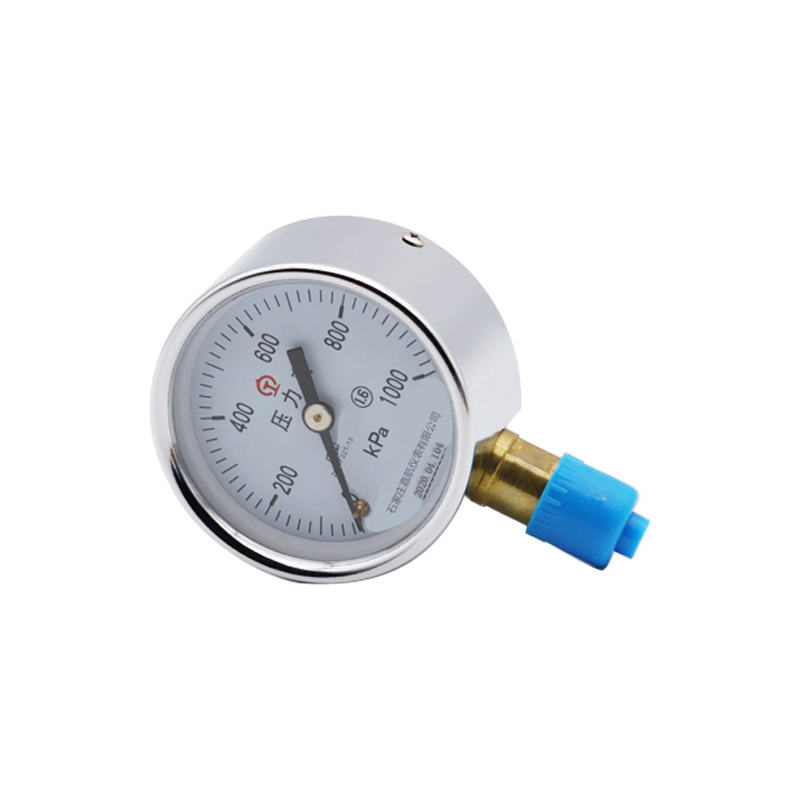

In the realm of precision instrumentation, OEM differential pressure gauges stand as a critical component across various industries. These devices measure the difference in pressure between two points, providing data critical for maintaining system integrity and performance. While their functionality is essential, understanding the pricing dynamics of OEM differential pressure gauges can be equally crucial for businesses. This article delves into the intricacies of these pricing structures, drawing from real-world experiences and expert insights.

Furthermore, the scale of production impacts pricing. Bulk purchasing of differential pressure gauges can lead to discounts, as manufacturers leverage economies of scale. This aspect is particularly vital for large-scale projects where substantial numbers of gauges are required, enabling significant cost advantages. Engaging with suppliers capable of large volume production can mitigate lead times and ensure a continuous supply chain, fostering trust and reliability in product availability. Technological advancements continually reshape the pricing landscape. For example, the integration of smart technology within differential pressure gauges, such as digital readouts and IoT connectivity, offers enhanced data insight and remote monitoring capabilities. These features, while adding upfront cost, can reduce maintenance expenses and improve system diagnostics over time. Industries keen on adopting a data-driven approach should consider these long-term financial benefits. The brand reputation and after-sales support offered by OEMs also influence differential pressure gauge prices. Established brands with proven engineering expertise often charge premium prices, justified by their commitment to quality assurance, comprehensive warranties, and robust customer support. However, the peace of mind these services provide is invaluable, particularly in mission-critical applications where downtime is not an option. Trustworthiness in the relationship between buyers and suppliers can significantly affect pricing. Suppliers who consistently demonstrate reliability, transparency, and expertise foster long-term partnerships, enabling more favorable negotiation opportunities. Trust is built over time through consistent delivery on promises, high-quality product offerings, and a customer-first approach. In conclusion, the price of OEM differential pressure gauges is dictated by various factors, including accuracy, materials, customization, production scale, technological features, and brand reputation. Understanding these elements through the lenses of experience, expertise, authoritativeness, and trustworthiness equips purchasers to make informed decisions that align with both performance requirements and budgetary constraints. Whether aiming for top-tier precision or cost-effective solutions, bringing clarity to pricing dynamics empowers stakeholders in optimizing their operational effectiveness and maintaining competitive advantage in their respective industries.

Furthermore, the scale of production impacts pricing. Bulk purchasing of differential pressure gauges can lead to discounts, as manufacturers leverage economies of scale. This aspect is particularly vital for large-scale projects where substantial numbers of gauges are required, enabling significant cost advantages. Engaging with suppliers capable of large volume production can mitigate lead times and ensure a continuous supply chain, fostering trust and reliability in product availability. Technological advancements continually reshape the pricing landscape. For example, the integration of smart technology within differential pressure gauges, such as digital readouts and IoT connectivity, offers enhanced data insight and remote monitoring capabilities. These features, while adding upfront cost, can reduce maintenance expenses and improve system diagnostics over time. Industries keen on adopting a data-driven approach should consider these long-term financial benefits. The brand reputation and after-sales support offered by OEMs also influence differential pressure gauge prices. Established brands with proven engineering expertise often charge premium prices, justified by their commitment to quality assurance, comprehensive warranties, and robust customer support. However, the peace of mind these services provide is invaluable, particularly in mission-critical applications where downtime is not an option. Trustworthiness in the relationship between buyers and suppliers can significantly affect pricing. Suppliers who consistently demonstrate reliability, transparency, and expertise foster long-term partnerships, enabling more favorable negotiation opportunities. Trust is built over time through consistent delivery on promises, high-quality product offerings, and a customer-first approach. In conclusion, the price of OEM differential pressure gauges is dictated by various factors, including accuracy, materials, customization, production scale, technological features, and brand reputation. Understanding these elements through the lenses of experience, expertise, authoritativeness, and trustworthiness equips purchasers to make informed decisions that align with both performance requirements and budgetary constraints. Whether aiming for top-tier precision or cost-effective solutions, bringing clarity to pricing dynamics empowers stakeholders in optimizing their operational effectiveness and maintaining competitive advantage in their respective industries.

Share

Latest news

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025