Août . 16, 2024 16:31 Back to list

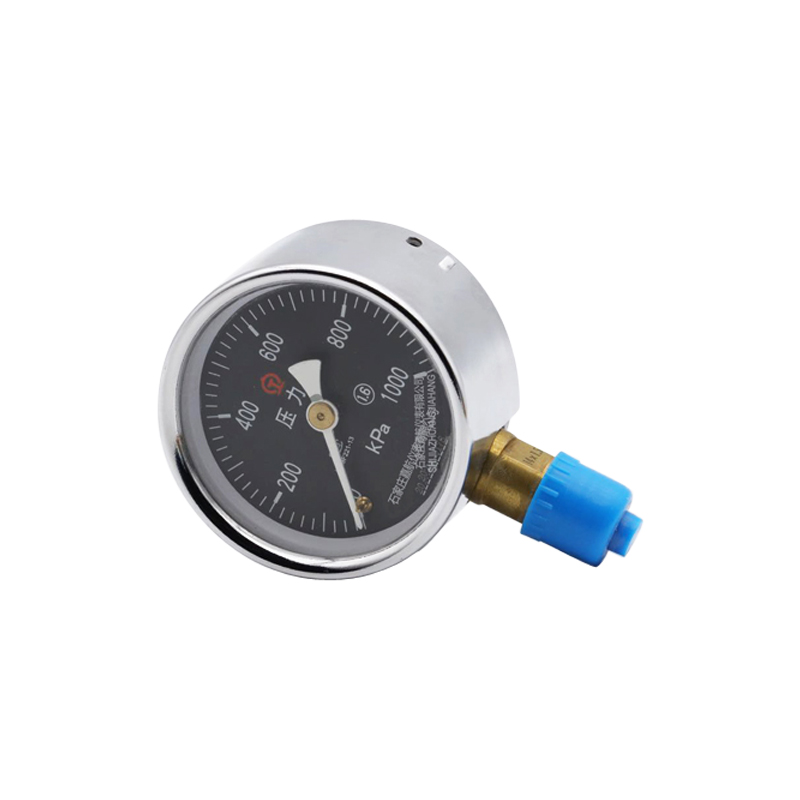

Purchase Flush Diaphragm Pressure Gauge for Accurate Measurements and Reliable Performance

Understanding Buy Flush Diaphragm Pressure Gauges Features and Benefits

When it comes to measuring pressure in various industrial applications, selecting the right equipment is crucial for accuracy and reliability. One such instrument gaining popularity is the flush diaphragm pressure gauge. Buying a flush diaphragm pressure gauge can significantly enhance the performance of your pressure measurement systems, and understanding its features and benefits can help make an informed decision.

What is a Flush Diaphragm Pressure Gauge?

A flush diaphragm pressure gauge is a type of pressure measurement device designed to handle viscous or crystalline fluids and slurries that may clog traditional gauges. The primary feature that distinguishes these gauges from conventional ones is the diaphragm, which is flush with the process connection. This design allows for a greater flow of the process fluid to the diaphragm, ensuring that pressure measurements are accurate and reliable.

Key Features of Flush Diaphragm Pressure Gauges

1. Clog-Resistant Design The flush diaphragm feature minimizes the risk of blockage, making it ideal for applications involving sticky or solids-laden fluids. This ensures continuous, reliable pressure readings without the need for frequent maintenance.

2. Variety of Materials Flush diaphragm pressure gauges can be manufactured from a range of materials, including stainless steel, Hastelloy, and other alloys. This flexibility allows for compatibility with various process fluids and environments, including corrosive and high-temperature applications.

3. Wide Pressure Range These gauges are available in multiple pressure ranges, making them suitable for use in diverse processes. Whether for low-pressure applications or high-pressure systems, there is likely a flush diaphragm pressure gauge designed to meet your needs.

4. Customization Options Many manufacturers offer customization options for flush diaphragm gauges, allowing users to tailor the instrument to specific applications. Customization may include changes in diaphragm thickness, process connection types, and other specifications.

buy flush diaphragm pressure gauge

5. Easy Installation and Maintenance The design of flush diaphragm pressure gauges often allows for straightforward installation, and due to their clog-resistant nature, they require less maintenance compared to traditional gauges.

Benefits of Buying Flush Diaphragm Pressure Gauges

1. Increased Accuracy By minimizing the accumulation of solids or viscous materials on the sensing element, flush diaphragm gauges can provide more accurate and consistent pressure readings over time.

2. Extended Lifespan The robust construction and resistance to clogging mean that these gauges often have a longer operational life, reducing the need for replacements and thereby lowering overall costs.

3. Improved Process Efficiency With reliable pressure readings, operators can make better-informed decisions, leading to optimized processes and enhanced productivity.

4. Versatility Flush diaphragm pressure gauges are used in various industries, including food and beverage, pharmaceuticals, wastewater treatment, and chemical processing. Their versatility makes them a valuable addition to any pressure measurement toolkit.

Conclusion

In summary, buying a flush diaphragm pressure gauge offers several advantages over traditional pressure measurement devices. With features that cater to the needs of various industries, these gauges provide accurate, reliable, and maintenance-friendly solutions for pressure measurement. When considering an investment in pressure gauges, understanding the unique benefits of flush diaphragm types can help ensure that you choose the right instrument for your specific application. Always consult with manufacturers or industry experts to select the most suitable gauge for your operational requirements, as this can lead to improved performance and significant cost savings in the long run.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025