अक्टूबर . 17, 2024 02:40 Back to list

Diaphragm Seal Pressure Gauge Exporters and Their Market Trends for Global Trade

Understanding Diaphragm Seal Type Pressure Gauges

Pressure measurement is crucial in various industries, ranging from oil and gas to food processing and pharmaceuticals. Different environments and mediums pose unique challenges, and one key solution to these challenges is the diaphragm seal type pressure gauge. This article explores what diaphragm seal type pressure gauges are, their advantages, applications, and the market dynamics surrounding their exportation.

What is a Diaphragm Seal Type Pressure Gauge?

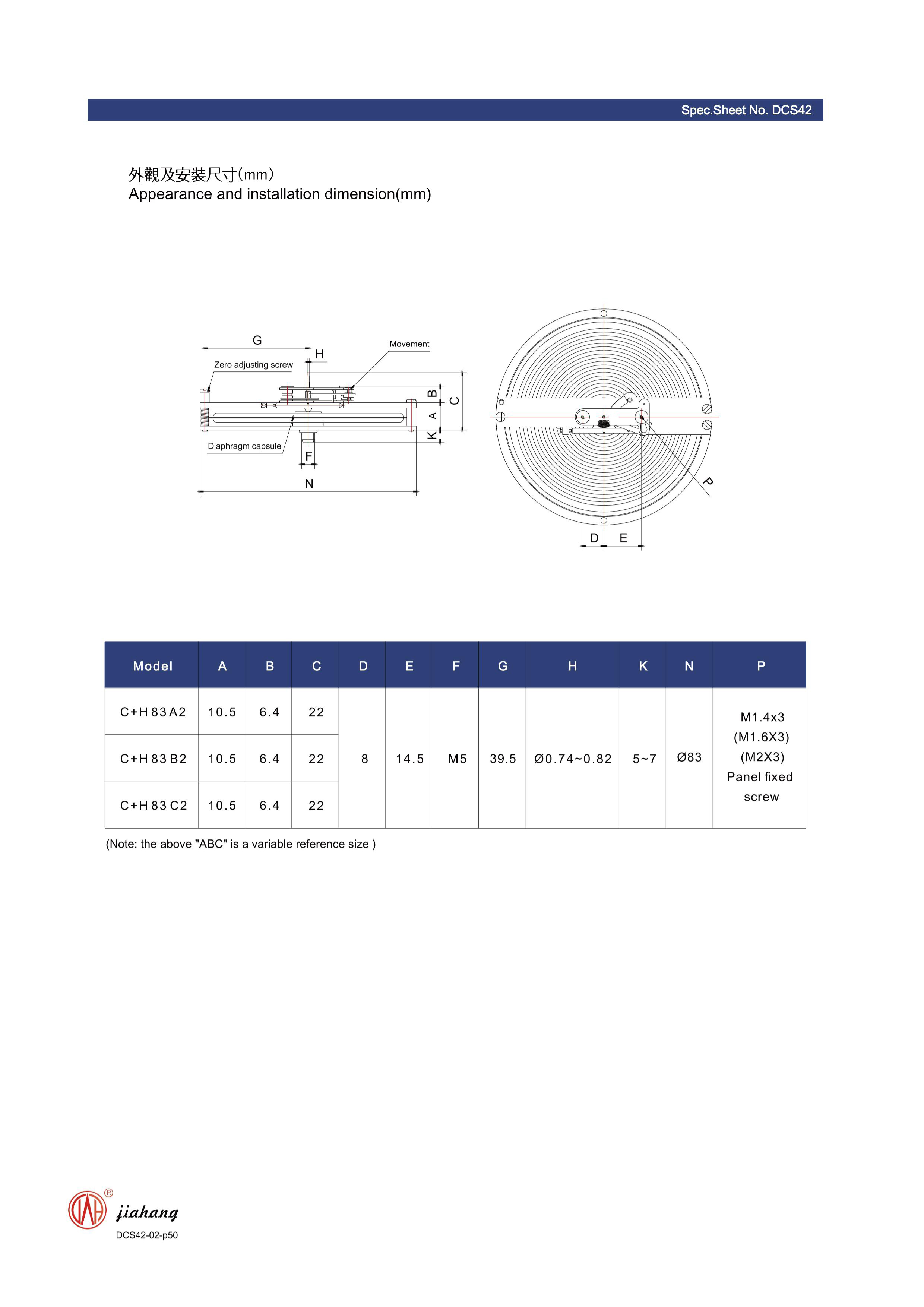

A diaphragm seal type pressure gauge is an instrument designed to measure the pressure of a medium in a process system while protecting the sensing element (usually a bourdon tube) from the direct effects of the medium. The diaphragm acts as a barrier between the process fluid and the measuring instrument, ensuring that corrosive, viscous, or dirty fluids do not come into contact with the sensitive components of the gauge. This is achieved through a flexible diaphragm made of materials such as stainless steel or other alloys that resist corrosion.

Advantages of Diaphragm Seal Type Pressure Gauges

1. Protection from Corrosive Environments One of the primary advantages of diaphragm seal type pressure gauges is their ability to shield the measuring element from corrosive substances. By isolating the gauge from direct contact with hostile media, these instruments can provide reliable measurements over extended periods.

2. Reduced Maintenance Needs Since the sensitive components of the gauge are not exposed to the process medium, the need for frequent maintenance and recalibration is significantly reduced. This leads to lower operational costs and increased efficiency, particularly in applications where downtime can be expensive.

3. Accuracy in Process Control Diaphragm seal type gauges offer a high level of accuracy, which is critical in process control applications. By ensuring that the measurement system remains unaffected by the medium’s characteristics, these gauges provide consistent and reliable readings.

4. Versatility in Applications These gauges can be used in various industries, including petrochemical, pharmaceutical, food and beverage, and water treatment. Their adaptability makes them a preferred choice for engineers and operators.

5. Ability to Handle Difficult Mediums Diaphragm seal type pressure gauges are designed to handle difficult media, such as slurries, pastes, or fluids with high viscosity. The diaphragm's movement allows the gauge to register pressure changes without being impeded by the thickness of the medium.

diaphragm seal type pressure gauge exporter

Applications Across Industries

The diaphragm seal type pressure gauge is employed in multiple sectors, including

- Oil and Gas Used in drilling operations, refineries, and pipelines to ensure safe and efficient operation. - Food and Beverage Processing Essential for monitoring pressures during processes such as brewing and bottling, where hygiene is a priority. - Pharmaceutical Manufacturing Critical for maintaining sterile environments and complying with industry regulations. - Water Treatment Facilities Employed to monitor pressures in various stages of water treatment, ensuring system integrity and safety.

Market Dynamics and Export Trends

The global market for diaphragm seal type pressure gauges is witnessing significant growth driven by increasing industrialization and stringent regulations regarding safety and quality control. As countries continue to develop their manufacturing and processing capabilities, the demand for accurate and reliable pressure measurement tools is rising.

Exporters of diaphragm seal type pressure gauges are focusing on enhancing product quality and durability, leveraging advancements in material science and technology. Additionally, customization options are becoming more prevalent, as industries increasingly require specific designs to meet unique operational demands.

Moreover, the growing emphasis on environmental sustainability encourages exporters to develop gauges that are not only effective but also eco-friendly in terms of both materials and manufacturing processes. This trend is particularly relevant in industries where regulatory compliance is strict.

Conclusion

Diaphragm seal type pressure gauges represent a vital component in modern industrial operations. Their ability to provide accurate, reliable measurements while protecting sensitive components from harmful media makes them indispensable in various sectors. As global markets expand and technology evolves, the demand for these gauges is likely to grow, presenting ample opportunities for exporters seeking to innovate and enhance product offerings. Understanding the advantages, applications, and market dynamics of diaphragm seal type pressure gauges can empower industries to optimize their processes and ensure safety.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025