सितम्बर . 03, 2024 22:16 Back to list

differential presure gauge company

Understanding Differential Pressure Gauges A Key Instrument in Various Industries

Differential pressure gauges play a critical role in many industrial applications, providing essential measurements that help maintain efficiency and safety in processes. These instruments measure the difference in pressure between two points in a system, offering vital data for monitoring and controlling various operations.

What is a Differential Pressure Gauge?

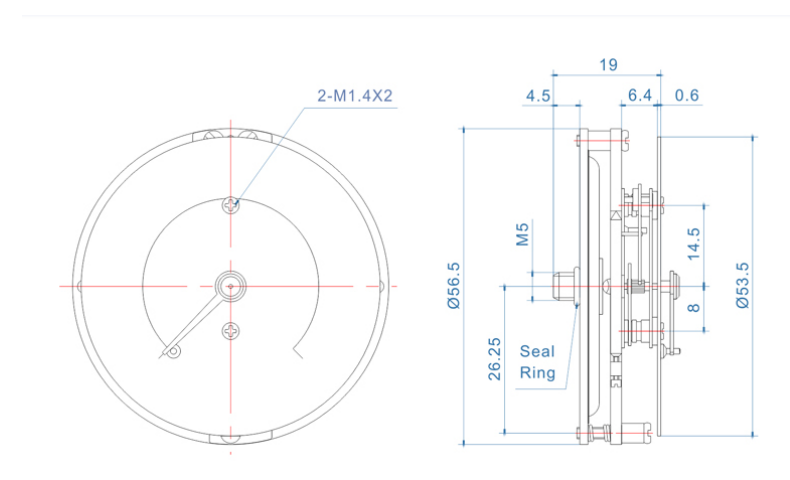

A differential pressure gauge is designed to measure the pressure difference between two locations. This measurement is crucial in processes such as filtration, chromatography, and HVAC systems, where pressure changes can indicate filter fouling, fluid flow rates, or system malfunctions. The gauge typically consists of two pressure ports connected to the source points, with a calibrated scale that displays the pressure differential.

Applications Across Industries

Differential pressure gauges are widely utilized across several industries, including oil and gas, water treatment, pharmaceuticals, and food processing. In oil and gas, for instance, they monitor pressures in pipelines to ensure consistent flow and prevent leaks. In water treatment facilities, these gauges help track filter performance, ensuring that the water remains clean and safe for consumption.

In the pharmaceutical industry, maintaining precise pressure conditions is crucial for product quality and safety. Differential pressure gauges help monitor the cleanliness of cleanrooms and other controlled environments, preventing contamination and ensuring compliance with stringent regulations. Similarly, in food processing, these gauges help verify that pressure levels are maintained during packaging and storage, safeguarding product integrity.

differential presure gauge company

Types of Differential Pressure Gauges

There are several types of differential pressure gauges available, each designed for specific applications. Mechanical gauges, often based on the Bourdon tube principle, provide a straightforward visual reading of pressure differences. Digital differential pressure gauges offer enhanced precision and can include features such as data logging and alarming capabilities, making them suitable for more complex systems.

Another option is the diaphragm gauge, which uses a flexible membrane to sense pressure changes. This type is often used in high-purity applications where contamination must be minimized. Moreover, there are specialized differential pressure sensors designed for corrosive environments, ensuring that the instruments can withstand the conditions without compromising accuracy or reliability.

Choosing the Right Gauge

When selecting a differential pressure gauge, it is essential to consider several factors, including the application, pressure range, and environmental conditions. Understanding the specific requirements of a process can guide the choice of gauge, ensuring that it meets operational needs while providing accurate and reliable measurements.

Conclusion

In conclusion, differential pressure gauges are vital instruments that ensure the efficient and safe operation of various industrial processes. By measuring pressure differences, they help identify issues before they escalate, contributing to system reliability and performance. As industries continue to evolve, the demand for accurate measurement instruments like differential pressure gauges will only increase, reaffirming their importance in modern engineering and process management.

-

Fluke Differential Pressure Gauges Precision Instruments for Industrial Use

NewsMay.25,2025

-

WIKA Differential Pressure Gauge 700.01 - High Accuracy & Durable Design

NewsMay.25,2025

-

Diaphragm Pressure Gauges High-Accuracy & Durable Solutions

NewsMay.25,2025

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025