दिसम्बर . 01, 2024 22:02 Back to list

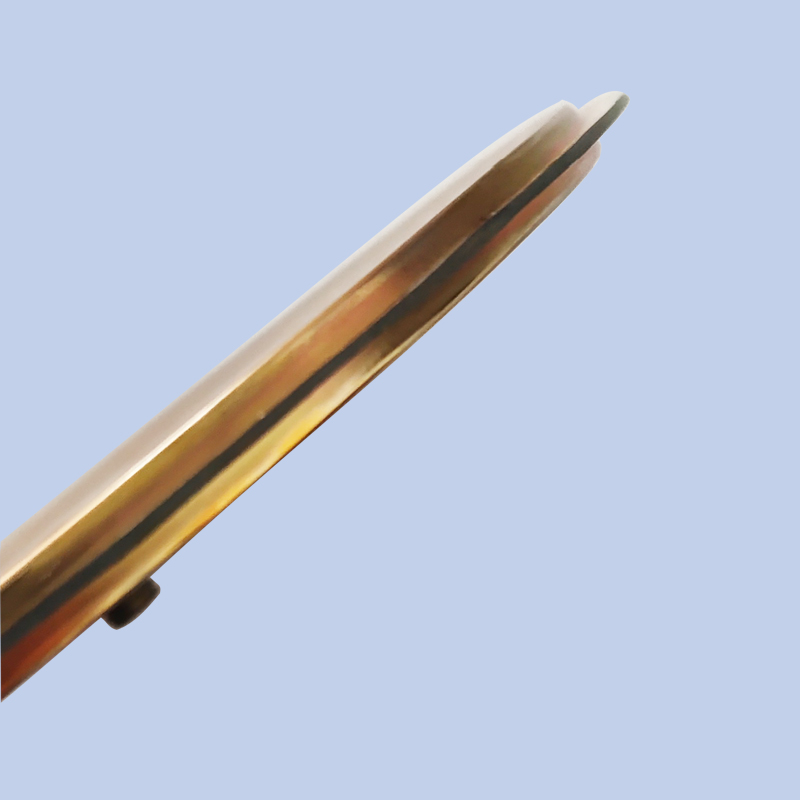

OEM WIKA Sanitary Diaphragm Pressure Gauge for Accurate Measurement Solutions

Understanding OEM WIKA Sanitary Diaphragm Pressure Gauges

In the realm of process engineering and manufacturing, the importance of accurate pressure measurement cannot be understated. Among the various types of pressure measuring instruments available, the OEM WIKA sanitary diaphragm pressure gauge stands out for its reliability, precision, and suitability for hygienic applications. This article delves into the key features, benefits, and applications of these specialized pressure gauges.

What is a Diaphragm Pressure Gauge?

A diaphragm pressure gauge operates using a flexible membrane or diaphragm that deflects in response to pressure changes. These gauges are particularly advantageous in applications where fluids might be corrosive, viscous, or contain solid particles, as they tend to have a sealed design that prevents direct contact between the pressure medium and the measuring element.

Importance of the Sanitary Design

The OEM WIKA sanitary diaphragm pressure gauge is specifically designed to meet the stringent hygiene standards required in industries such as food and beverage, pharmaceuticals, and biotechnology. The term sanitary refers to the gauge’s construction materials and finish, which are all compliant with health regulations. Typically, these gauges are made from stainless steel, ensuring that they are not only durable and resistant to corrosion but also easy to clean and sterilize.

Key Features of OEM WIKA Sanitary Diaphragm Pressure Gauges

1. Hygienic Design The product is designed to prevent any contamination, which is crucial in applications where product integrity is pivotal. Smooth surfaces and minimal crevices ensure that no residual material remains after cleaning.

2. Versatility WIKA offers a range of diaphragm pressure gauges that can be used across various applications. Whether monitoring steam pressure in food processing plants or measuring the pressure of sterile liquids in pharmaceutical manufacturing, these gauges provide exceptional reliability.

3. Extensive Measurement Range OEM WIKA gauges can accommodate various pressure ranges, making them suitable for diverse operational environments. This flexibility is essential in system design, allowing engineers to select gauges that precisely meet their application needs.

oem wika sanitary diaphragm pressure gauge

4. Digital and Analog Options WIKA provides both digital and analog variants of their sanitary diaphragm pressure gauges. Digital gauges can offer advanced features such as data logging, alarms, and connectivity, whereas analog gauges can provide quick readings at a glance.

5. Robust Performance Built to withstand harsh conditions, these gauges maintain accuracy and functionality under varying temperatures and pressures, ensuring minimal downtime and reduced maintenance costs.

Applications of OEM WIKA Sanitary Diaphragm Pressure Gauges

Due to their hygienic design and robustness, OEM WIKA sanitary diaphragm pressure gauges are commonly used in several critical industries

- Food and Beverage In processes such as pasteurization, brewing, and bottling, maintaining optimal pressure is vital for product quality and safety.

- Pharmaceuticals The production of medications requires strict adherence to sanitary standards, and these gauges help ensure that pressure-related processes remain within specified limits.

- Biotechnology In the development of biological products, pressure monitoring is essential for maintaining the integrity of the materials involved.

- Water Treatment Monitoring pressure in treatment systems helps to ensure effective operation and safety in the delivery of potable water.

Conclusion

The OEM WIKA sanitary diaphragm pressure gauge is an exemplary instrument in the field of pressure measurement, designed specifically for applications necessitating sanitary conditions. Its robust construction, versatility, and reliability make it an indispensable tool in industries where precision and hygiene are paramount. As technology advances, the role of such specialized gauges will only become more critical in maintaining standards and ensuring safety across numerous applications. Investing in quality instruments like the OEM WIKA sanitary diaphragm pressure gauge is key to achieving operational excellence and safety in today’s demanding industrial environments.

-

Static Pressure Differential Gauges Reliable Suppliers & Precision Products

NewsMay.14,2025

-

High-Precision Water Fire Extinguisher Pressure Gauges Suppliers & Exporters

NewsMay.14,2025

-

Fire Extinguisher Gauge Pressure Solutions Reliable Water Extinguisher Suppliers

NewsMay.14,2025

-

High-Precision Mini Differential Pressure Gauge Compact & Durable Design

NewsMay.13,2025

-

Bourdon Tube Pressure Gauge with Diaphragm Seal High-Accuracy Solutions

NewsMay.13,2025

-

Wise Differential Pressure Gauge High-Precision & Reliable Solutions

NewsMay.12,2025