जुलाई . 31, 2024 06:40 Back to list

Precision Pressure Gauges for Accurate Measurements in Industrial Applications Across India

Precision Pressure Gauges in India Importance and Applications

Precision pressure gauges play a crucial role in various industries, ensuring accurate measurement and monitoring of pressure levels. In India, where industrial growth is on the rise, the demand for high-quality precision pressure gauges has increased significantly. These instruments are vital for maintaining operational efficiency, safety, and compliance with regulatory standards.

Understanding Precision Pressure Gauges

Precision pressure gauges are instruments designed to measure the pressure of gases or liquids with high accuracy. Unlike standard pressure gauges, precision gauges utilize advanced engineering and materials to minimize errors and enhance reliability. They typically come equipped with features such as stainless steel casings, high-precision diaphragms, and calibration options to meet stringent industrial standards.

Key Applications

1. Manufacturing In manufacturing processes, consistent pressure is essential for optimal performance. Precision pressure gauges are critical for monitoring pressures in hydraulic systems, pneumatic systems, and other machinery, ensuring that operations run smoothly and efficiently.

2. Oil and Gas Industry The oil and gas sector relies heavily on precise pressure measurements for the extraction, transportation, and refining of petroleum products. Precision pressure gauges help in monitoring wellhead pressures, pipeline pressures, and other critical points, ensuring safe operations and minimizing the risk of leaks and accidents.

3. Pharmaceuticals In the pharmaceutical industry, precision is paramount. Pressure gauges are employed in various processes, including sterilization and the manufacturing of pharmaceutical products. Ensuring the correct pressure levels in sterile environments is vital for product safety and efficacy.

4. Food and Beverage The food and beverage industry also utilizes precision pressure gauges to maintain quality and safety standards. These gauges monitor pressures in processes such as carbonating beverages, pasteurization, and packaging, ensuring that products meet regulatory requirements.

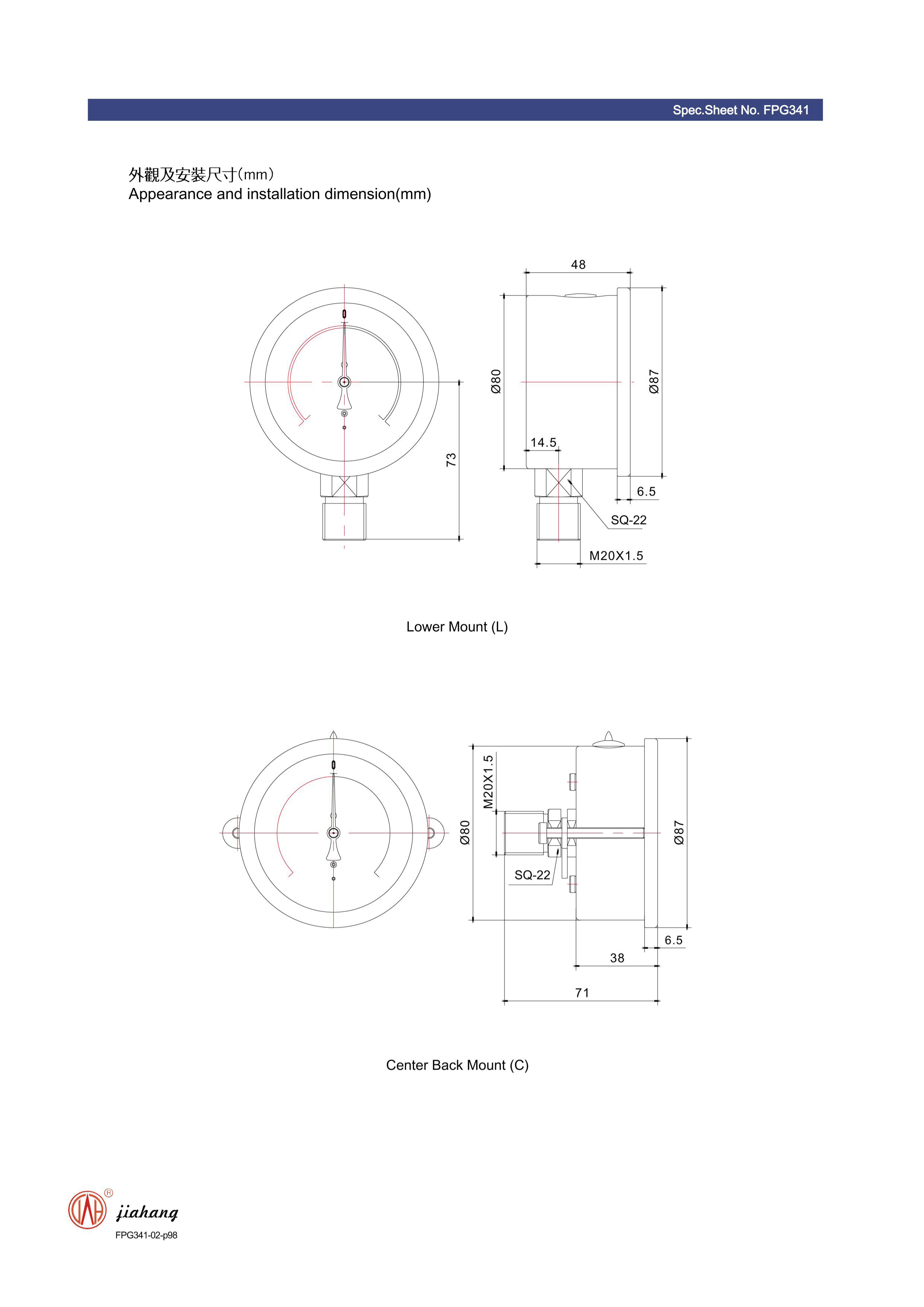

precision pressure gauges india

5. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, monitoring pressure is essential for maintaining system performance and energy efficiency. Precision pressure gauges help technicians diagnose issues and optimize system operations.

Benefits of Using Precision Pressure Gauges

1. Accuracy The primary advantage of precision pressure gauges is their ability to provide highly accurate readings. This accuracy is essential for processes where even minor deviations can lead to significant consequences.

2. Durability Built from robust materials such as stainless steel, precision pressure gauges are designed to withstand harsh environments, ensuring longevity and reliability.

3. Ease of Calibration Many precision gauges offer easy calibration options. This ability to recalibrate ensures that the instruments maintain their accuracy over time, which is especially important in industries where compliance with standards is required.

4. Wide Range of Applications The versatility of precision pressure gauges means they can be used across various industries, making them a valuable investment for businesses looking to enhance their operational capabilities.

Conclusion

In India, the importance of precision pressure gauges cannot be overstated. As industries continue to grow and evolve, the need for accurate measurement tools becomes even more critical. Precision pressure gauges not only ensure operational efficiency but also play a significant role in maintaining safety standards and compliance in various sectors. Investing in high-quality precision pressure gauges is a step toward achieving excellence and reliability in industrial operations, contributing to the overall growth of the Indian economy. As technology advances, the future holds promise for even more sophisticated pressure measurement solutions, further enhancing the capabilities of Indian industries.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025