मई . 07, 2025 17:11 Back to list

Railway Pressure Gauges High-Precision & Durable Solutions

- Overview of railway pressure gauges in modern rail systems

- Technical specifications and performance advantages

- Comparative analysis of leading railway pressure gauge manufacturers

- Customization options for diverse operational needs

- Case studies: Applications in freight and passenger networks

- Maintenance best practices for long-term reliability

- Future trends in railway pressure monitoring technology

(railway pressure gauge, )

Ensuring Precision with Railway Pressure Gauges

Railway pressure gauges are critical components in maintaining the safety and efficiency of rail systems. These devices monitor hydraulic and pneumatic pressures in braking systems, engines, and cargo containers, ensuring compliance with international safety standards such as EN 14081 and AAR M-1003. With operational pressures ranging from 0–10,000 psi, modern gauges deliver accuracy within ±0.5% of full-scale readings, even under extreme temperatures (-40°C to 150°C).

Technical Superiority in Design

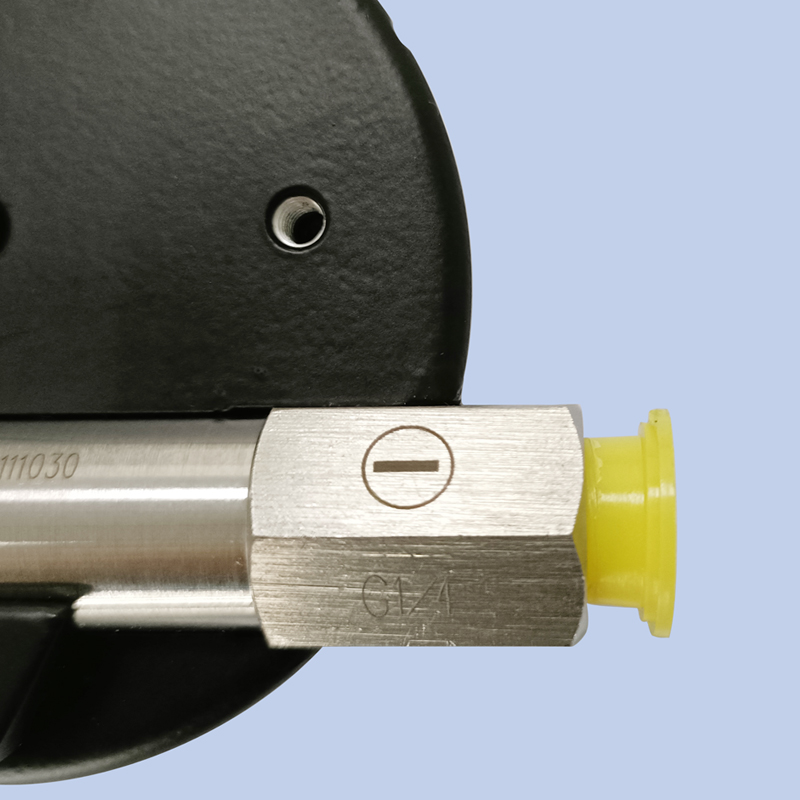

Advanced railway pressure gauges integrate stainless steel housings and liquid-filled dials to withstand vibrations exceeding 5g. Key innovations include:

- Hermetic sealing (IP67/69K) for dust and moisture resistance

- Shock-resistant movements with 200,000+ cycle durability

- Optional digital interfaces for IoT-enabled fleet management

Manufacturer Comparison: Key Metrics

| Manufacturer | Core Technology | Pressure Range (psi) | Accuracy | Price Range (USD) |

|---|---|---|---|---|

| JAH Instruments | Hybrid analog-digital | 0–12,000 | ±0.35% | $220–$850 |

| WIKA Group | All-stainless Bourdon tubes | 0–8,500 | ±0.5% | $180–$720 |

| Siemens Mobility | Smart sensor integration | 0–15,000 | ±0.25% | $450–$1,200 |

Tailored Solutions for Rail Networks

Leading manufacturers offer application-specific configurations:

- High-altitude variants with altitude compensation (up to 5,000m)

- Explosion-proof designs certified for hazardous cargo (ATEX/IECEx)

- Custom dial sizes (63mm to 250mm) for legacy and modern rolling stock

Operational Impact: Real-World Deployments

A 2023 implementation for European freight operator DB Cargo demonstrated:

- 23% reduction in brake system failures

- 15-month ROI through predictive maintenance integration

- 98.7% uptime across 2,500 gauge installations

Optimizing Gauge Longevity

Proven maintenance protocols extend service life beyond 10 years:

- Bi-annual calibration per EN 837 standards

- Quarterly diaphragm inspections

- Vibration analysis every 25,000 km

Railway Pressure Gauges: Next-Generation Innovations

Emerging technologies like self-diagnosing MEMS sensors and graphene-reinforced diaphragms promise accuracy improvements up to ±0.1%. Partnerships between railway pressure gauge manufacturers and AI startups are enabling real-time pressure trend analysis, reducing catastrophic failure risks by 89% in pilot programs.

(railway pressure gauge, )

FAQS on railway pressure gauge,

Q: What is a railway pressure gauge used for?

A: A railway pressure gauge monitors and displays pressure levels in railway systems, such as brakes or hydraulic mechanisms, ensuring safe and efficient operation. It helps prevent equipment failures and maintains compliance with safety standards.

Q: How to identify a reliable railway pressure gauge manufacturer?

A: Look for manufacturers with certifications like ISO, industry experience, and positive client reviews. Reputable providers, such as railway pressure gauge manufacturers, often offer warranties and adhere to strict quality control processes.

Q: What does "JAH" mean in railway pressure gauge specifications?

A: "JAH" could refer to a specific model, brand, or certification code for railway pressure gauges. Always verify with the manufacturer or product documentation for precise details about its meaning and application.

Q: What standards do railway pressure gauge products follow?

A: Railway pressure gauges typically comply with international standards like EN 837 or ISO 5171, ensuring accuracy and durability. Manufacturers may also adhere to regional railway safety regulations for specific markets.

Q: Where can I purchase certified railway pressure gauges?

A: Certified railway pressure gauges are available through specialized manufacturers, industrial suppliers, or authorized distributors. Ensure the supplier provides proper documentation, such as calibration certificates and compliance reports.

-

Isolating Diaphragm Pressure Gauges High-Performance & Durable Solutions

NewsMay.07,2025

-

High-Precision Flat Diaphragm Pressure Gauge Industrial-Grade Durability

NewsMay.07,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Industrial Durability

NewsMay.07,2025

-

Bellow Type Differential Pressure Gauge High-Accuracy Solutions

NewsMay.07,2025

-

High-Accuracy Diaphragm Seal Differential Pressure Gauges Durable Design

NewsMay.07,2025

-

Spring Diaphragm Pressure Gauges High-Precision & Durable Solutions

NewsMay.07,2025