नवम्बर . 16, 2024 23:57 Back to list

Manufacturers of Spring Diaphragm Pressure Gauges for Accurate Measurement Solutions

Understanding Spring Diaphragm Pressure Gauge Factories

Spring diaphragm pressure gauges are critical instruments in various industries, primarily used for measuring pressure in gases and liquids. These gauges utilize a flexible diaphragm that deflects under pressure, translating mechanical motion into a readable pressure measurement. The manufacturing process of these gauges is sophisticated, requiring precision engineering and quality control to ensure reliability and accuracy.

The factories producing spring diaphragm pressure gauges play a vital role in meeting the growing demands of sectors such as oil and gas, water treatment, and pharmaceuticals. In these industries, maintaining accurate pressure readings is paramount for process safety and operational efficiency. As a result, the design and manufacturing processes at these factories focus on advanced technologies and stringent quality standards.

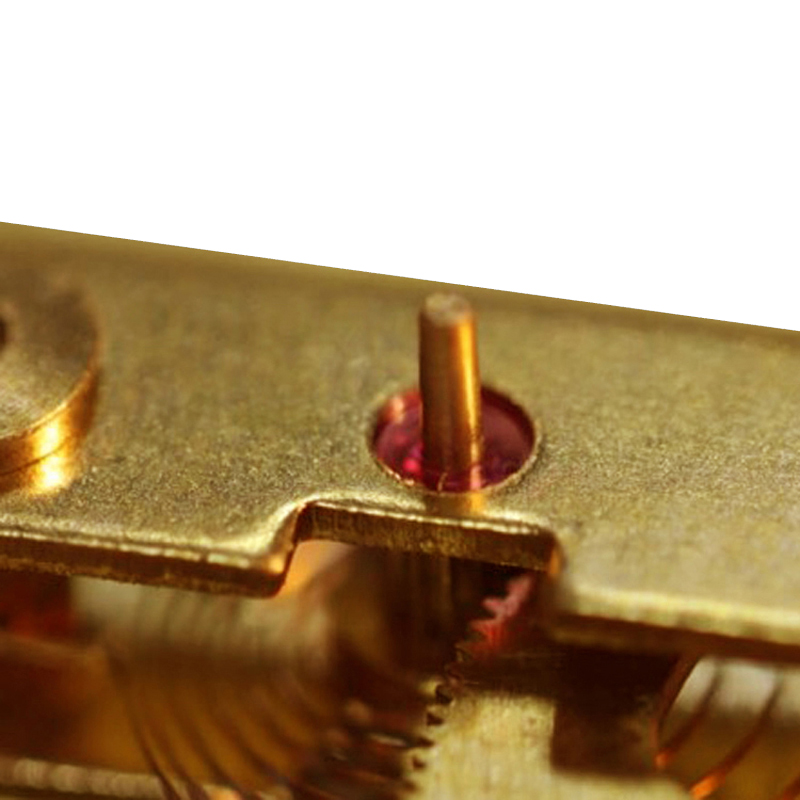

One of the fundamental aspects of producing high-quality spring diaphragm pressure gauges is the selection of materials. Factories typically use stainless steel, brass, or specialized alloys that are resistant to corrosion and suitable for high-pressure environments. The choice of material significantly impacts the gauge's durability and performance, making it a critical consideration during the manufacturing process.

spring diaphragm pressure gauge factories

In addition to material selection, the production process involves several stages, including machining, assembly, and calibration. Advanced machining techniques, such as CNC (Computer Numerical Control), are often employed to achieve precise dimensions and tolerances. This level of precision is essential because even minor discrepancies can lead to inaccurate pressure readings.

Furthermore, assembly requires skilled labor to ensure that each component functions correctly. This includes installing the diaphragm, spring, and other mechanical parts that contribute to the gauge's operation. After assembly, the gauges undergo a rigorous calibration process to verify their accuracy against known pressure standards before they are ready for distribution.

Quality control measures are paramount in manufacturing environments. Factories implement stringent quality assurance procedures to test the finished products. This may involve pressure testing, performance verification, and environmental testing to simulate real-world conditions. These tests help assure customers that the gauges meet industry standards and perform reliably in demanding applications.

In conclusion, spring diaphragm pressure gauge factories are integral to the supply chain of many industries. Their focus on quality materials, precision manufacturing, and thorough testing ensures that these gauges can provide accurate measurements crucial for safety and efficiency in operations. As technology continues to advance, these factories will play an essential role in developing innovative pressure measurement solutions that meet the ever-evolving needs of the market.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025