अक्टूबर . 11, 2024 10:17 Back to list

wholesale differential pressure gauge with diaphragm seal

Understanding Wholesale Differential Pressure Gauges with Diaphragm Seal

In today's industrial landscape, the need for precise measurement and monitoring of pressure is paramount. Among the various tools available for this task, wholesale differential pressure gauges with diaphragm seals stand out for their reliability and accuracy. This article will explore what these gauges are, how they work, and their key applications, helping professionals understand their importance in various industries.

What is a Differential Pressure Gauge?

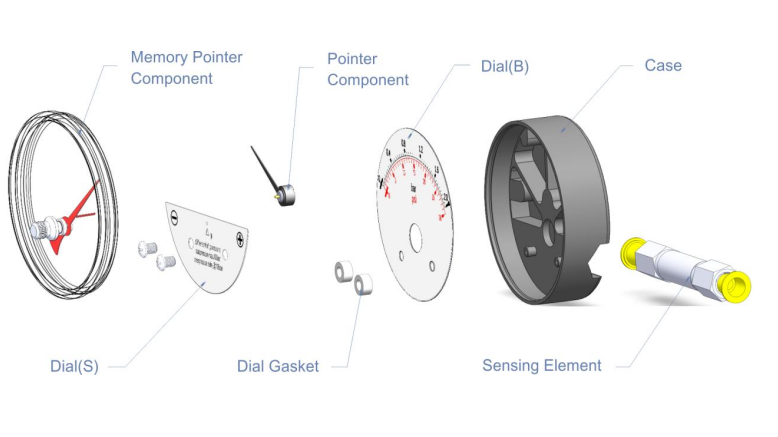

A differential pressure gauge is an instrument used to measure the difference in pressure between two points within a system. This measurement is essential in various applications, from monitoring fluid flows in pipelines to assessing the performance of HVAC systems. These gauges work on the principle of sensing the pressure difference and translating it into a readable output, typically displayed on a dial or digital readout.

The Role of Diaphragm Seals

The diaphragm seal plays a critical role in differential pressure measurement. This component consists of a flexible membrane that separates the measuring instrument from the process fluid. This separation is particularly useful in applications involving corrosive, viscous, or high-temperature fluids that could damage the gauge. The diaphragm can respond to pressure changes without direct exposure to the measuring fluid, ensuring accuracy and prolonging the life of the equipment.

Benefits of Diaphragm Seals in Differential Pressure Gauges

1. Protection Against Corrosion Many industrial processes involve fluids that can be highly corrosive (e.g., acids or salts). Diaphragm seals protect the internal workings of the gauge from these damaging substances, enhancing the lifespan of the instrument.

2. Reduced Maintenance With a diaphragm in place, the need for frequent calibration and maintenance is reduced. This reliability translates to lower operational costs for businesses.

3. Wide Range of Applications Diaphragm-sealed differential pressure gauges are versatile and can be used across a range of industries, including oil and gas, water treatment, pharmaceuticals, and food processing.

4. Improved Sensitivity The sensitivity of diaphragm gauges allows for the detection of minor changes in pressure, which is crucial for applications where precise monitoring is essential.

wholesale differential pressure gauge with diaphragm seal

How They Work

Differential pressure gauges with diaphragm seals function through a straightforward mechanism. When a pressure difference occurs between the two points being measured, it exerts a force on the diaphragm. This force causes the diaphragm to deflect, and this deflection is then translated into a pressure reading via an internal mechanism, such as a mechanical linkage or electronic sensor.

The accuracy of the reading depends on several factors, including the materials used for the diaphragm, the design of the gauge, and the calibration process. High-quality materials and construction techniques can substantially improve the performance and reliability of the gauge.

Applications in Industry

1. HVAC Systems In heating, ventilation, and air conditioning systems, these gauges monitor filter pressure drops to ensure efficient airflow and maintenance schedules.

2. Water and Wastewater Management They are used to measure flow rates and pressure drops across treatment systems, helping operators optimize processes and maintain compliance with regulatory standards.

3. Oil and Gas Monitoring pressure in pipelines is crucial for safety; diaphragm-sealed gauges help in detecting leaks and ensuring the integrity of the system.

4. Pharmaceutical Manufacturing In this highly regulated industry, precise pressure measurement is essential for quality control and maintaining sterile environments.

Conclusion

Wholesale differential pressure gauges with diaphragm seals are indispensable tools in many industrial applications. Their ability to measure pressure differences accurately while protecting the instrument from hostile environments makes them a preferred choice across various sectors. Understanding their functionality, benefits, and applications can aid professionals in selecting the right equipment for their specific needs, ultimately leading to enhanced safety, efficiency, and productivity in their operations. As industries continue to evolve, the role of these gauges will remain crucial, ensuring that systems operate effectively and safely in an ever-complex environment.

-

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

NewsMay.23,2025

-

Industrial Differential Pressure Gauges Global Supplier & Pricelist

NewsMay.23,2025

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025