Jun . 28, 2024 13:20 Back to list

3. Pressure Difference Gauges

The Evolution of Differential Pressure Gauges A Comprehensive Guide

Differential pressure gauges are essential tools in a wide range of industries, from HVAC systems to industrial processes. These instruments measure the difference in pressure between two points and are used to monitor and control various parameters such as flow rate, level, and leakage. In this article, we will explore the types of differential pressure gauges available and their applications in different industries.

One of the most common types of differential pressure gauges is the Bourdon tube gauge. This gauge consists of a flexible metal tube that is bent into a coil shape. When pressure is applied to one end of the tube, it deflects, causing the other end to move. This movement is then converted into an electrical signal that can be read on a dial or digital display. Bourdon tube gauges are known for their accuracy and reliability and are commonly used in high-pressure applications.

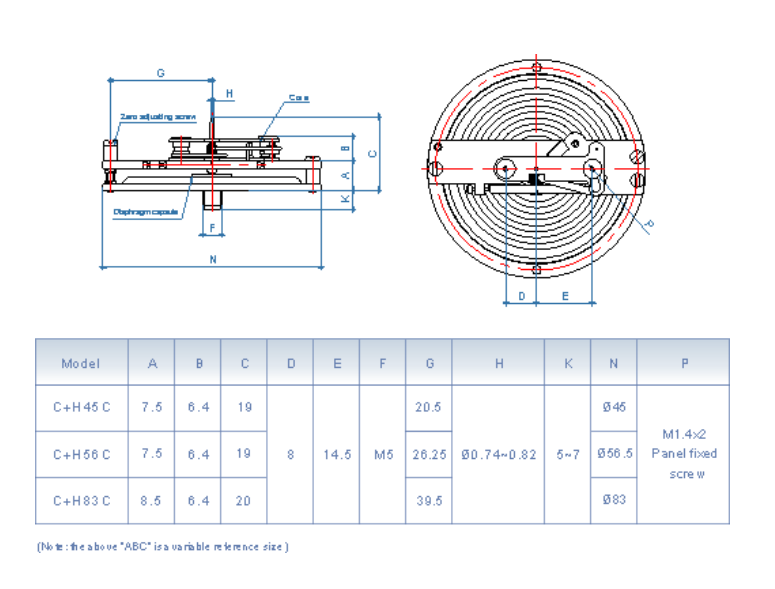

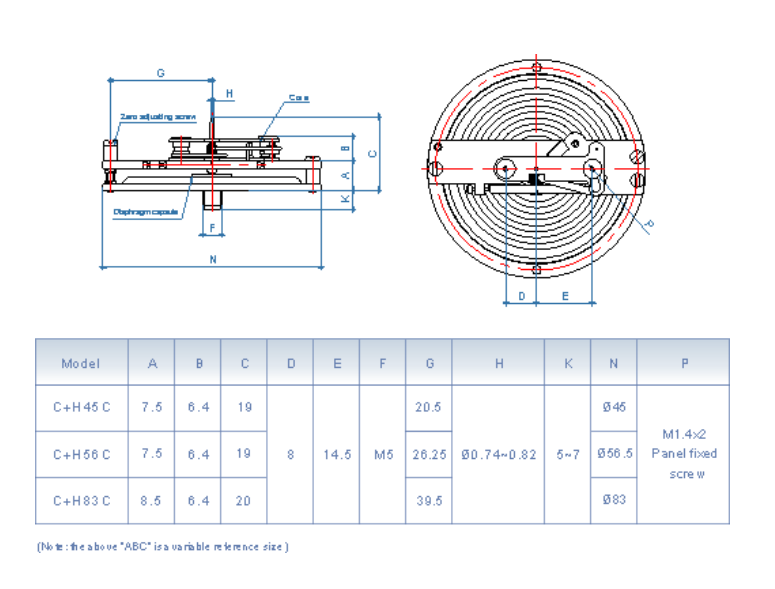

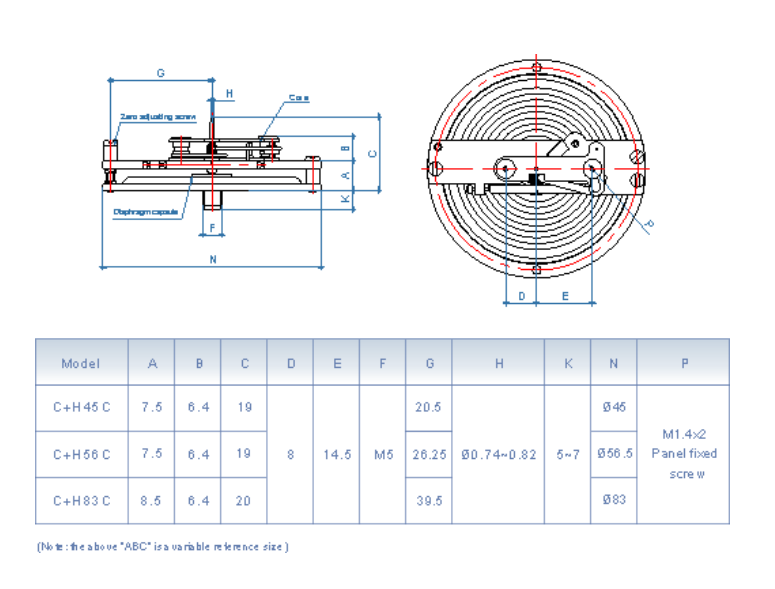

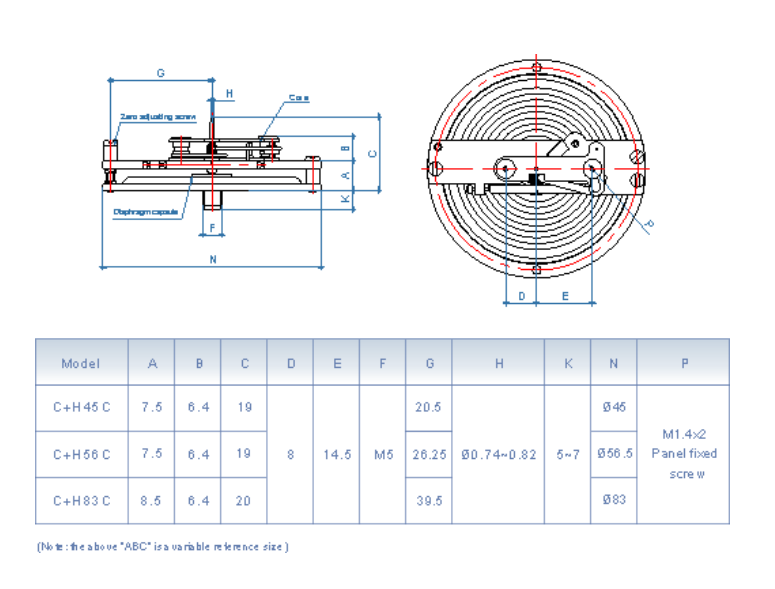

Another popular type of differential pressure gauge is the diaphragm gauge. This gauge uses a flexible diaphragm to measure pressure differences. The diaphragm is placed between two chambers, one of which is exposed to the pressure being measured. As the pressure difference changes, the diaphragm deflects, and this deflection is measured by a sensor that converts it into an electrical signal As the pressure difference changes, the diaphragm deflects, and this deflection is measured by a sensor that converts it into an electrical signal As the pressure difference changes, the diaphragm deflects, and this deflection is measured by a sensor that converts it into an electrical signal As the pressure difference changes, the diaphragm deflects, and this deflection is measured by a sensor that converts it into an electrical signal

As the pressure difference changes, the diaphragm deflects, and this deflection is measured by a sensor that converts it into an electrical signal As the pressure difference changes, the diaphragm deflects, and this deflection is measured by a sensor that converts it into an electrical signal types of differential pressure gauges product. Diaphragm gauges are often used in applications where the process fluid may contain solids or corrosive substances.

Magnetic differential pressure gauges use a magnetic coupling to transmit the pressure difference across a barrier. These gauges are designed for use in hazardous environments where traditional pressure gauges may not be suitable. They are also used in applications where the process fluid is at high temperatures or pressures.

Differential pressure transmitters are another type of instrument that combines the functionality of a differential pressure gauge with additional features such as signal conditioning and communication capabilities. These transmitters are often used in automated control systems and can provide real-time data for process optimization.

In conclusion, differential pressure gauges are versatile instruments that play a crucial role in many industrial processes. From simple Bourdon tube gauges to sophisticated differential pressure transmitters, these instruments come in a variety of types and configurations to meet the specific needs of different applications. Whether you need to measure low pressures in HVAC systems or high pressures in industrial processes, there is a differential pressure gauge that can help you achieve your goals.

types of differential pressure gauges product. Diaphragm gauges are often used in applications where the process fluid may contain solids or corrosive substances.

Magnetic differential pressure gauges use a magnetic coupling to transmit the pressure difference across a barrier. These gauges are designed for use in hazardous environments where traditional pressure gauges may not be suitable. They are also used in applications where the process fluid is at high temperatures or pressures.

Differential pressure transmitters are another type of instrument that combines the functionality of a differential pressure gauge with additional features such as signal conditioning and communication capabilities. These transmitters are often used in automated control systems and can provide real-time data for process optimization.

In conclusion, differential pressure gauges are versatile instruments that play a crucial role in many industrial processes. From simple Bourdon tube gauges to sophisticated differential pressure transmitters, these instruments come in a variety of types and configurations to meet the specific needs of different applications. Whether you need to measure low pressures in HVAC systems or high pressures in industrial processes, there is a differential pressure gauge that can help you achieve your goals.

As the pressure difference changes, the diaphragm deflects, and this deflection is measured by a sensor that converts it into an electrical signal As the pressure difference changes, the diaphragm deflects, and this deflection is measured by a sensor that converts it into an electrical signal

As the pressure difference changes, the diaphragm deflects, and this deflection is measured by a sensor that converts it into an electrical signal As the pressure difference changes, the diaphragm deflects, and this deflection is measured by a sensor that converts it into an electrical signal types of differential pressure gauges product. Diaphragm gauges are often used in applications where the process fluid may contain solids or corrosive substances.

Magnetic differential pressure gauges use a magnetic coupling to transmit the pressure difference across a barrier. These gauges are designed for use in hazardous environments where traditional pressure gauges may not be suitable. They are also used in applications where the process fluid is at high temperatures or pressures.

Differential pressure transmitters are another type of instrument that combines the functionality of a differential pressure gauge with additional features such as signal conditioning and communication capabilities. These transmitters are often used in automated control systems and can provide real-time data for process optimization.

In conclusion, differential pressure gauges are versatile instruments that play a crucial role in many industrial processes. From simple Bourdon tube gauges to sophisticated differential pressure transmitters, these instruments come in a variety of types and configurations to meet the specific needs of different applications. Whether you need to measure low pressures in HVAC systems or high pressures in industrial processes, there is a differential pressure gauge that can help you achieve your goals.

types of differential pressure gauges product. Diaphragm gauges are often used in applications where the process fluid may contain solids or corrosive substances.

Magnetic differential pressure gauges use a magnetic coupling to transmit the pressure difference across a barrier. These gauges are designed for use in hazardous environments where traditional pressure gauges may not be suitable. They are also used in applications where the process fluid is at high temperatures or pressures.

Differential pressure transmitters are another type of instrument that combines the functionality of a differential pressure gauge with additional features such as signal conditioning and communication capabilities. These transmitters are often used in automated control systems and can provide real-time data for process optimization.

In conclusion, differential pressure gauges are versatile instruments that play a crucial role in many industrial processes. From simple Bourdon tube gauges to sophisticated differential pressure transmitters, these instruments come in a variety of types and configurations to meet the specific needs of different applications. Whether you need to measure low pressures in HVAC systems or high pressures in industrial processes, there is a differential pressure gauge that can help you achieve your goals. Share

Latest news

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025

-

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

NewsMay.23,2025

-

Industrial Differential Pressure Gauges Global Supplier & Pricelist

NewsMay.23,2025

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025