Nov . 30, 2024 08:47 Back to list

Top Low Pressure Diaphragm Pressure Gauges for Accurate Measurements

Understanding the Best Low Pressure Diaphragm Pressure Gauges

Pressure gauges are critical instruments used in various industries, including manufacturing, oil and gas, pharmaceuticals, and HVAC systems. Among the various types of pressure gauges available, low-pressure diaphragm pressure gauges are particularly useful for measuring pressures in the range of 0-30 psi. This article will explore the features, applications, and benefits of the best low-pressure diaphragm pressure gauges.

What is a Low Pressure Diaphragm Pressure Gauge?

A low pressure diaphragm pressure gauge operates by translating the pressure of a fluid into a mechanical movement. The core of this technology is the diaphragm, a flexible membrane that responds to pressure changes. When pressure is applied, the diaphragm bends, and this movement is transmitted to a mechanical linkage connected to a dial or electronic display, indicating the pressure reading.

These gauges are typically designed for low-pressure applications where accuracy and reliability are paramount. They can measure both gases and liquids, making them versatile tools for various industries.

Key Features of Quality Low Pressure Diaphragm Gauges

1. Accuracy High-quality low-pressure diaphragm gauges provide precise measurements, essential for processes where pressure control is critical.

2. Durability Diaphragm gauges are often constructed from materials resistant to corrosion and wear, ensuring longevity and consistent performance under challenging conditions.

3. Sensitivity They are designed to detect small pressure changes, which is crucial for applications that require fine-tuning.

4. Various Scale Options Leading manufacturers offer gauges with multiple scale options to suit different operational requirements, ensuring flexibility in applications.

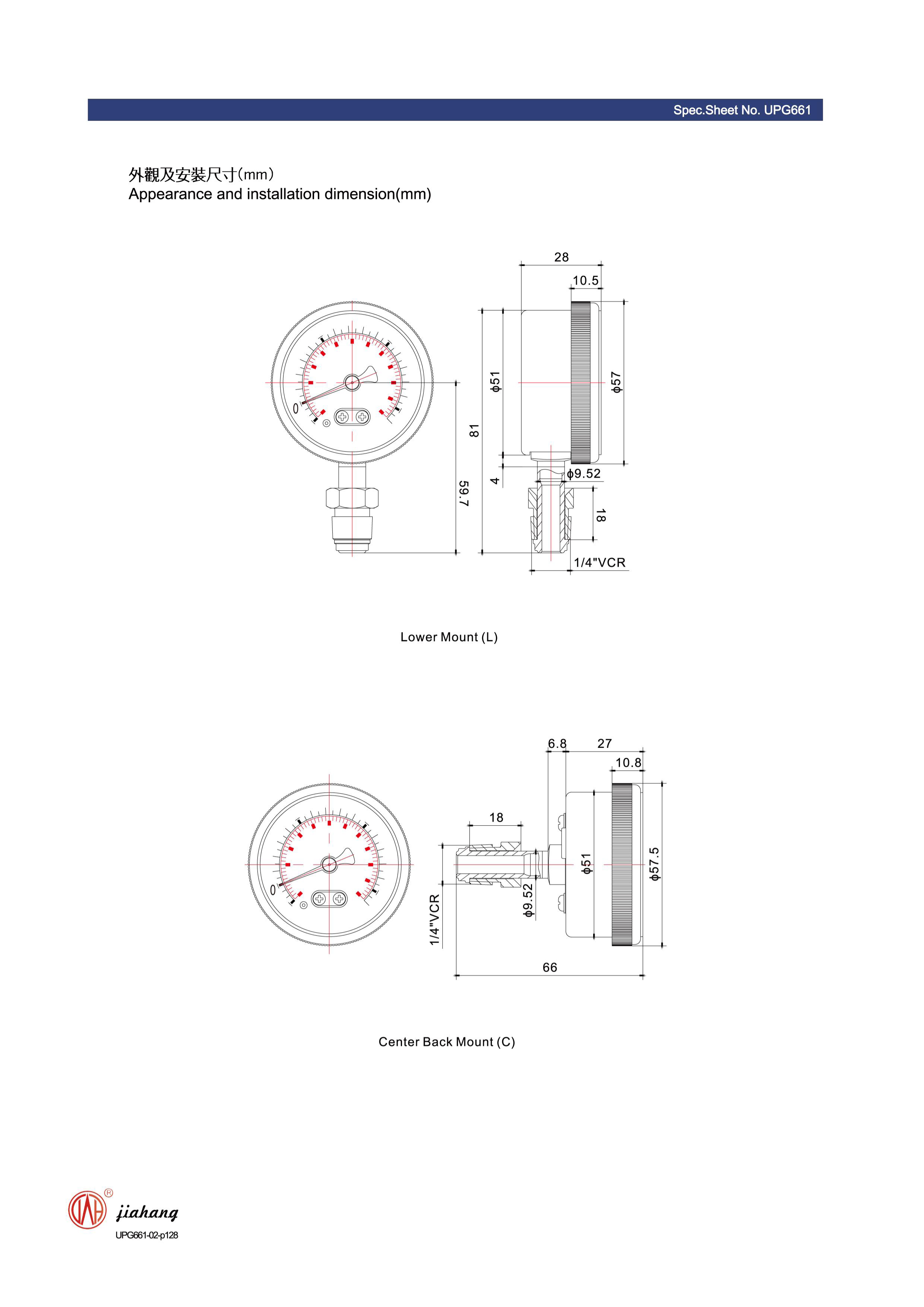

5. Connection Types These gauges come with various connection types, such as threaded or flange, allowing for easy integration into existing systems.

Common Applications

best low pressure diaphragm pressure gauges

Low pressure diaphragm pressure gauges are commonly used in several sectors

- HVAC Systems They help monitor pressure levels in heating and cooling systems, ensuring optimal performance and energy efficiency.

- Pump Systems These gauges provide critical feedback for pumps, especially in applications where precise pressure monitoring is essential.

- Food and Beverage Industry In processing plants, these gauges ensure that product quality standards are met by monitoring pressure during various stages of production.

- Pharmaceutical Manufacturing Accurate pressure measurements are vital for compliance with health regulations and ensuring product safety.

Benefits of Using Low Pressure Diaphragm Gauges

1. Enhanced Performance Monitoring Using diaphragm gauges allows for constant monitoring of pressure levels, leading to improved overall equipment performance and reliability.

2. Safety Accurate pressure readings help prevent over-pressurization and potential equipment failures, safeguarding both personnel and operations.

3. Cost-Effective Investing in quality low-pressure diaphragm gauges can lead to long-term savings by reducing the chances of equipment failure and downtime.

4. User-Friendly Many modern diaphragm gauges are designed for easy readability, with clear dials or digital displays, facilitating quick interpretation of measurements.

Conclusion

Choosing the best low-pressure diaphragm pressure gauge is crucial for ensuring efficient and safe operations across various industries. Their accuracy, durability, and versatility make them indispensable tools in monitoring and controlling pressure, ultimately contributing to enhanced performance and safety in numerous applications. By understanding the features and benefits of these gauges, businesses can make informed decisions, leading to successful operational outcomes. Whether in HVAC systems, pharmaceuticals, or manufacturing, the right low-pressure diaphragm pressure gauge can have a lasting impact on efficiency and effectiveness.

-

HD Fire Pressure Gauges High Accuracy & Durable Solutions

NewsMay.28,2025

-

Custom Singles Capsule Systems Top Exporters & Factories

NewsMay.28,2025

-

Piston-Style Differential Pressure Gauges Precision & Durability

NewsMay.28,2025

-

WIKA Differential Pressure Gauge 700.04 High-Accuracy Industrial Measurement

NewsMay.28,2025

-

Precision Differential Pressure Gauge Factory Custom Solutions & OEM Services

NewsMay.27,2025

-

Pressure Diaphragm Capsule Elements High-Accuracy & Durable Solutions

NewsMay.27,2025