Agu . 01, 2024 00:01 Back to list

Differential Pressure Gauge with Needle Indicator Designed for Efficient Water Filtration Monitoring System

Understanding Differential Pressure Gauges with Needle Valves for Water Filter Applications

In various industrial and municipal applications, maintaining the efficiency of water filtration systems is paramount. One of the crucial tools used to monitor the performance of these systems is the differential pressure gauge, often paired with a needle valve. This combination allows operators to ensure the effective functioning of water filters and to implement timely maintenance procedures.

What is a Differential Pressure Gauge?

A differential pressure gauge is a device designed to measure the difference in pressure between two points in a system. In the context of water filtration, it typically measures the pressure before and after a filter. This measurement is essential because it provides insights into the filter's condition. As a filter becomes clogged with contaminants, the pressure drop across it increases. By monitoring this differential pressure, operators can determine when maintenance or replacement of the filter is necessary, thus preventing system inefficiencies and potential failures.

The Role of the Needle Valve

A needle valve is a type of valve with a small port and a threaded, needle-like plunger. It is used to precisely control the flow of fluids in a system. When paired with a differential pressure gauge, the needle valve allows for fine-tuning of pressure readings. By adjusting the valve, operators can manipulate the flow of fluid through the gauge, ensuring that the readings are accurate and reflective of the actual pressure differential across the filter.

This precision is particularly important in water filter applications, where even slight variations in pressure can indicate significant changes in filter performance

. The needle valve facilitates the calibration of the gauge, allowing for adjustments based on the specific characteristics of the water system, such as flow rate and temperature.Importance in Water Filter Service

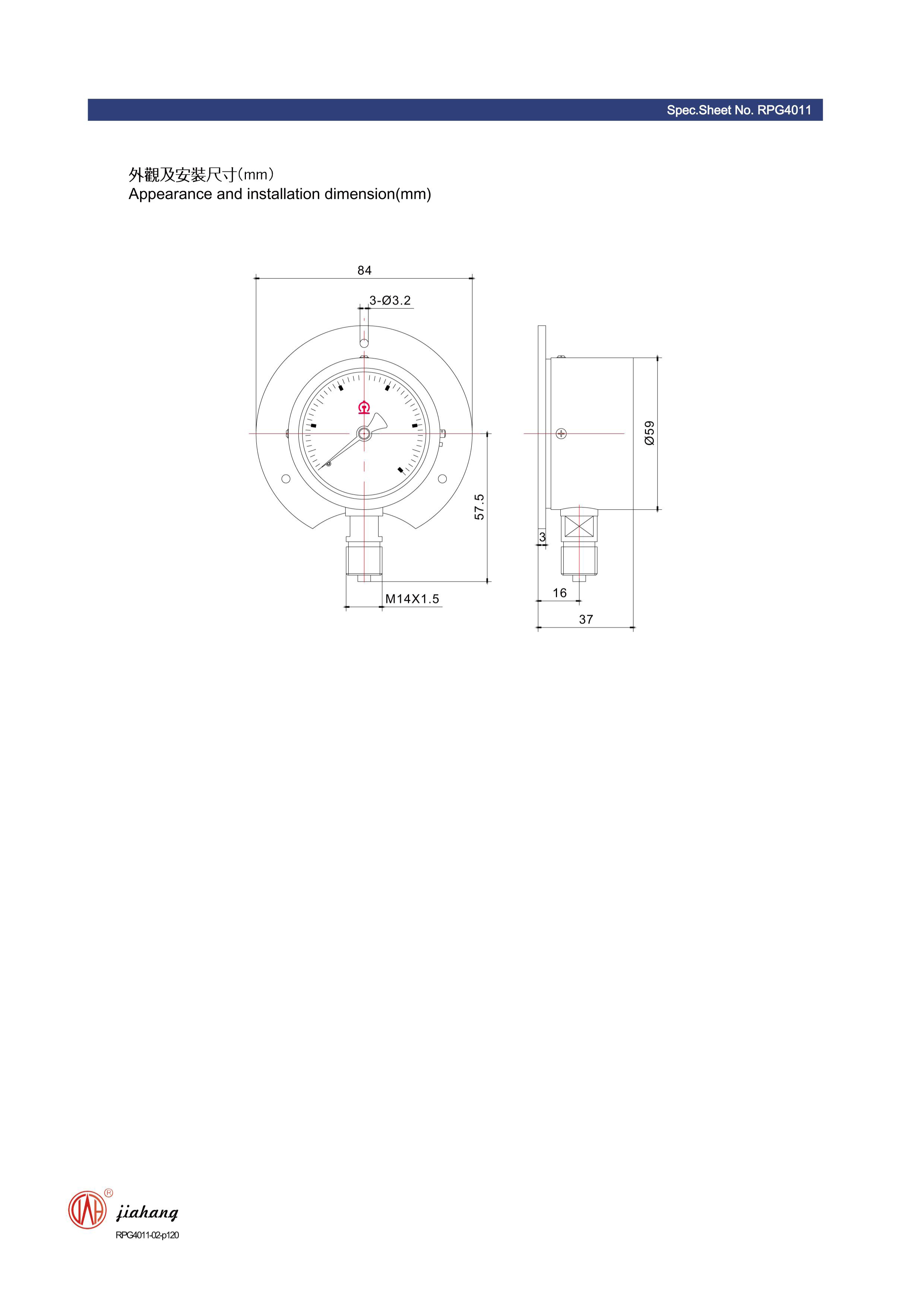

differential pressure gauge with needle for water filter service

In water filtration, maintaining optimal performance is crucial for various reasons, including compliance with health and safety standards, ensuring clean water supply, and prolonging the lifespan of the filtration equipment. Using a differential pressure gauge with a needle valve offers several advantages

1. Timely Maintenance By continuously monitoring the pressure differential, operators can detect clogged filters before they lead to system failure or water quality issues. This proactive approach facilitates timely maintenance, reducing downtime and repair costs.

2. Enhanced Efficiency Maintaining the correct pressure differential optimizes the filter's performance, ensuring that it operates within its designed capabilities. This leads to better filtration efficiency and improved water quality.

3. Cost Savings Regular monitoring and maintenance of filters prevent excessive strain on the system, which can lead to costly repairs or replacements. Additionally, optimizing filter performance can reduce energy consumption associated with pumping systems.

4. Data Tracking Many modern differential pressure gauges come with data logging capabilities. This technology allows for the tracking of pressure readings over time, enabling operators to identify trends and make informed decisions concerning system upgrades or replacements.

Conclusion

In summary, differential pressure gauges with needle valves are essential tools in the monitoring and maintenance of water filtration systems. By providing accurate measurements of pressure differences, these devices help ensure efficient filter operation, prolong equipment lifespan, and maintain water quality. For any organization dependent on clean water supply, investing in these technologies can lead to significant operational improvements and cost savings.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025