Agu . 06, 2024 08:26 Back to list

Exploring the Features and Applications of Low Range Differential Pressure Gauges in China

Understanding Low Range Differential Pressure Gauges in China

Differential pressure gauges are essential instruments used across various industries to measure pressure differences between two points in a system. In the context of China, the demand for low range differential pressure gauges has been growing due to the rapid industrialization and the increasing need for precise measurements in various applications such as HVAC systems, filtration processes, and process control in manufacturing.

What is a Low Range Differential Pressure Gauge?

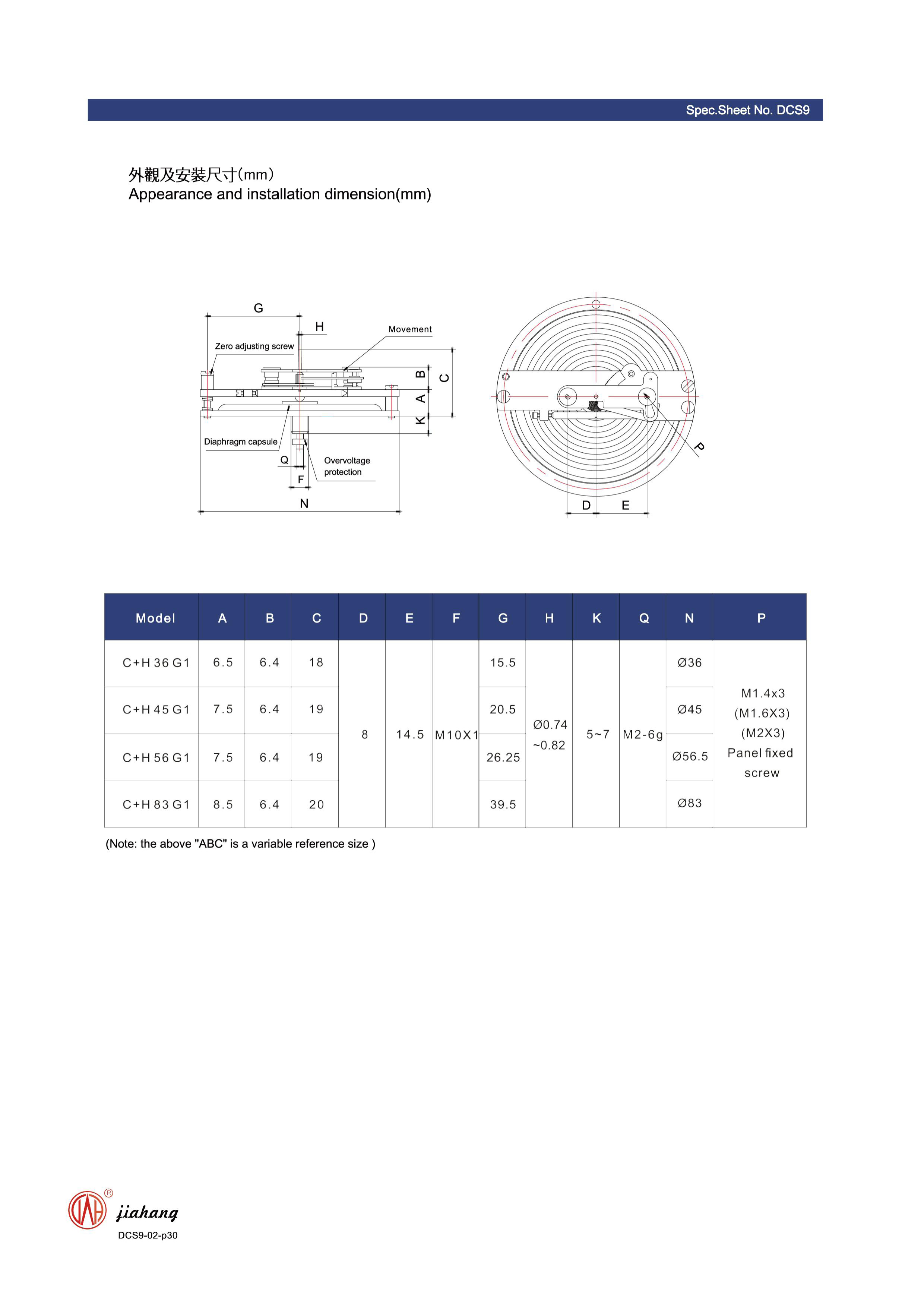

A low range differential pressure gauge is specifically designed to measure small pressure differences, typically in the range of 0 to 25 inches of water column (WC). These gauges use a diaphragm or a similar mechanism to sense the pressure difference, converting it into a readable output. The low range capability makes them particularly suitable for applications where high accuracy and sensitivity are crucial, such as in medical devices, air filtration monitoring, and environmental controls.

Applications in Industry

In China, low range differential pressure gauges find extensive applications in industries such as pharmaceuticals, food processing, and semiconductor manufacturing. For instance, in the pharmaceutical sector, maintaining sterile environments is critical. Low range gauges are employed to monitor the pressure differentials in cleanrooms and to ensure that contaminants do not enter these sensitive areas.

Moreover, in HVAC (Heating, Ventilation, and Air Conditioning) systems, these gauges are vital for ensuring proper airflow and filter performance. An increase in differential pressure may indicate that an air filter is becoming clogged, prompting maintenance before system efficiency declines. In semiconductor manufacturing, where contamination can be catastrophic, low range differential pressure gauges help maintain the integrity of clean zones.

Advantages of Low Range Differential Pressure Gauges

1. Accuracy Low range differential pressure gauges provide accurate and reliable measurements, which are crucial for processes that require stringent controls. Their sensitivity allows them to detect even minute pressure changes, making them indispensable in many applications.

china low range differential pressure gauge

2. Durability Modern low range differential pressure gauges are designed to withstand harsh environments, including high humidity and extreme temperatures, which is particularly important in industrial settings across China.

3. Ease of Use Many of these gauges come with digital displays, making them user-friendly. Operators can easily read and interpret the data, which can also be connected to computer systems for data logging and remote monitoring.

4. Cost-Effectiveness With their growing availability and the advent of digital technologies, low range differential pressure gauges have become more affordable. This cost-effectiveness encourages wider adoption across various sectors in China.

Challenges in the Market

Despite their advantages, the market for low range differential pressure gauges in China faces challenges. One major issue is the presence of several manufacturers producing low-quality gauges. This can lead to reliability issues and inaccurate readings, which can significantly impact operational efficiency and safety. Therefore, it is crucial for buyers to choose reputable suppliers who adhere to international standards.

Moreover, as industries move towards automation, there is a growing demand for smart differential pressure gauges that can integrate with IoT systems. Suppliers need to innovate and provide products that not only meet the traditional measurements but also offer advanced capabilities.

Conclusion

As the industrial landscape in China continues to evolve, the importance of low range differential pressure gauges cannot be overstated. Their application across various industries highlights a growing trend toward precision and efficiency in operations. By addressing challenges and embracing innovations, the market for these gauges is poised for significant growth, contributing to improved process control and safety in numerous applications. As industries increasingly rely on accurate data to make informed decisions, the role of differential pressure measurement will remain critical.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025