Nov . 06, 2024 22:06 Back to list

Popular Bellow Type Differential Pressure Gauges for Accurate Measurements

Understanding the Bellow Type Differential Pressure Gauge

Differential pressure gauges are essential instruments used across various industries to measure the difference in pressure between two points in a system. Among the different types of differential pressure gauges available, the bellow type stands out due to its design, precision, and wide range of applications. This article aims to provide an in-depth understanding of the bellow type differential pressure gauge, its working principles, advantages, and areas of application.

What is a Bellow Type Differential Pressure Gauge?

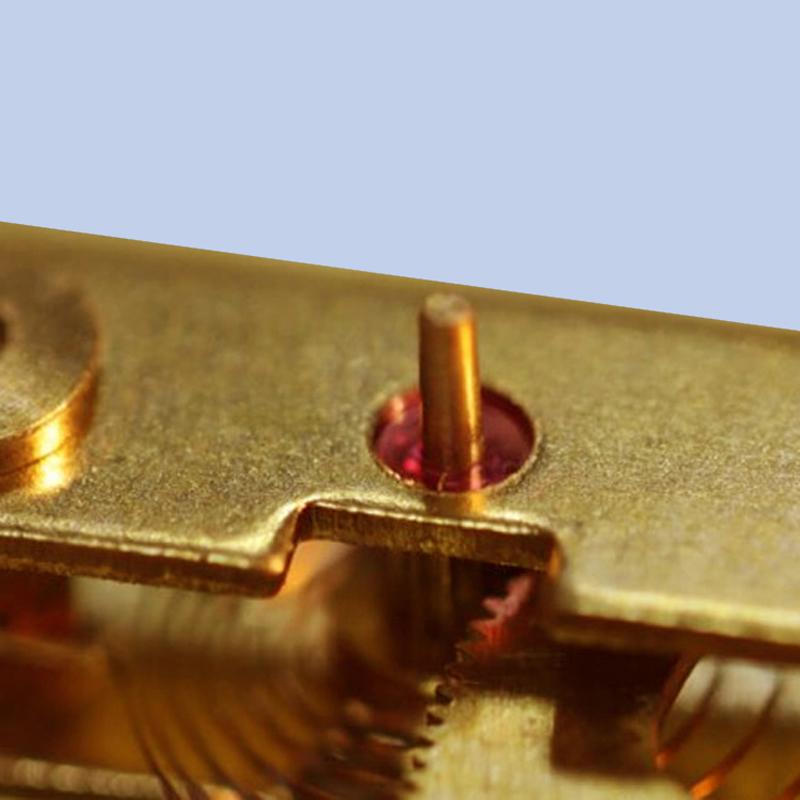

A bellow type differential pressure gauge utilizes a mechanical bellow element to measure pressure differences. The bellow is a flexible, typically cylindrical component made from materials such as stainless steel or bronze, designed to expand and contract in response to pressure changes. When pressure is applied to the bellow from two different sources, it causes the bellow to deform, which is then translated into a readable measurement on the gauge.

Working Principle

The working principle of the bellow type differential pressure gauge is relatively straightforward. The gauge consists of two inlet ports for connecting to the required pressure points. As the pressure enters the bellow, the difference in pressure causes one side of the bellow to expand more than the other. This movement is mechanically linked to a pointer that moves across a calibrated scale on the gauge, providing a direct reading of the pressure difference.

One key advantage of the design is its ability to handle both low and high pressures effectively. The bellow can measure small pressure changes with high accuracy, making it ideal for sensitive applications. The flexible nature of the bellow also allows for a more generous range of motion, which can enhance the readability of pressure changes.

Advantages of Bellow Type Gauges

1. Accuracy and Sensitivity Bellow type differential pressure gauges are known for their high precision and sensitivity. Their design enables them to detect minute changes in pressure, which is crucial in various applications where accuracy is paramount.

famous differential pressure gauge bellow type

2. Durable Construction Typically constructed from resilient materials, bellow type gauges offer a long service life. They can withstand harsh industrial conditions, including exposure to corrosive substances, high temperatures, and mechanical stress.

3. Minimal Maintenance These gauges require minimal maintenance when properly installed and used within their specified pressure ranges. Their simple mechanical design means there are fewer components that could fail or require servicing.

4. Versatile Applications Bellow type differential pressure gauges are suitable for a broad range of applications, including HVAC systems, filtration monitoring, and liquid level measurements in tanks. Their versatility extends to use in both gaseous and liquid media, making them a preferred choice in many industries.

5. Clear Readings The mechanical display feature of these gauges allows for easy and clear readings, without the need for electronic components. This can be particularly advantageous in environments where electronic devices may be prone to failure or interference.

Applications of Bellow Type Differential Pressure Gauges

The applications of bellow type differential pressure gauges span across numerous sectors. In the HVAC industry, they are often used to monitor air and water pressure differences, ensuring efficient system operation. In the oil and gas industry, these gauges play a critical role in monitoring line pressures and ensuring safety protocols are followed.

Furthermore, they are widely used in the pharmaceutical and food industries, where maintaining proper pressure differentials is essential for safety and quality assurance. In laboratories, bellow type gauges help maintain accurate pressure readings in various experimental setups.

Conclusion

In summary, bellow type differential pressure gauges are versatile instruments that offer high accuracy, durability, and minimal maintenance. Their mechanical design ensures reliability across various industrial applications, making them a preferred choice for engineers and technicians alike. As industries continue to evolve and demand greater precision and efficiency, the bellow type differential pressure gauge will undoubtedly remain a vital tool in maintaining optimal operational standards. Whether you are dealing with HVAC systems, fluid dynamics, or any other application requiring precise pressure measurement, these gauges stand out as a dependable solution.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025