Nov . 20, 2024 18:11 Back to list

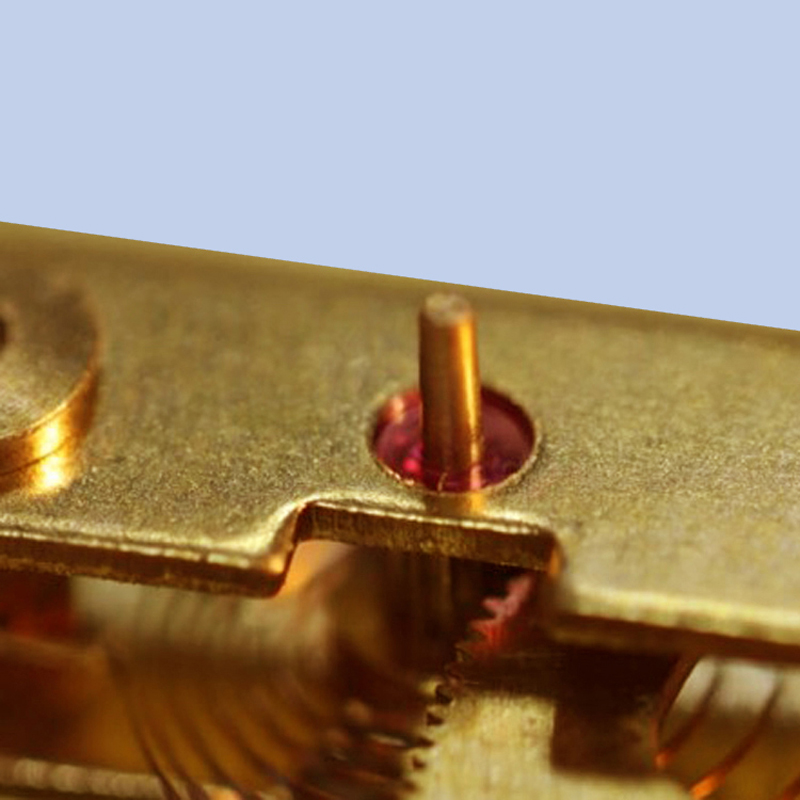

high quality diaphragm pressure element

The Importance of High-Quality Diaphragm Pressure Elements in Modern Applications

In many industrial and scientific applications, accurate pressure measurement and control are critical. One of the key components that facilitate these capabilities is the diaphragm pressure element. Understanding the significance of high-quality diaphragm pressure elements can provide insights into their impact on various industries, from manufacturing to pharmaceuticals.

What is a Diaphragm Pressure Element?

A diaphragm pressure element is a mechanical device used to measure changes in pressure, typically within fluid or gas systems. It consists of a flexible membrane or diaphragm that deforms in response to external pressure, translating this mechanical deformation into a measurable electrical signal. This allows for both absolute and gauge pressure measurements, making diaphragm pressure elements versatile for numerous applications.

Why Quality Matters

The performance of diaphragm pressure elements is heavily influenced by their quality. High-quality materials and manufacturing processes ensure that these devices have improved durability, stability, and precision. Here are several reasons why investing in high-quality diaphragm pressure elements is essential

1. Accuracy and Reliability High-quality diaphragm pressure elements provide precise measurements, which is crucial in applications where even minor deviations can lead to significant issues. For instance, in pharmaceuticals, incorrect pressure readings can result in unsafe product formulations. Reliable pressure readings ensure safety and efficacy in product development and production.

2. Durability and Longevity In harsh environments, such as those found in oil and gas industries, diaphragm pressure elements are exposed to extreme temperatures, corrosive substances, and high levels of vibration. High-quality elements are often made from advanced materials that resist degradation and wear, offering longer service life and reducing the need for frequent replacements. This durability translates to cost savings over time.

3. Temperature and Pressure Resistance The ability of a diaphragm pressure element to maintain accuracy across a range of temperatures and pressures is vital. High-quality elements are designed to operate effectively under varying conditions and can withstand significant pressure changes without losing their calibration integrity.

4. Minimized Hysteresis Hysteresis refers to the lag between input and output when the pressure changes. High-quality diaphragm pressure elements are engineered to minimize this effect, ensuring that the measurements are consistent and reliable across multiple cycles of pressure application. This characteristic is particularly important in closed-loop control systems where precise feedback is required.

high quality diaphragm pressure element

5. Ease of Integration Quality diaphragm pressure elements often come with standardized outputs (like 4-20 mA or digital signals) and can be easily integrated into existing systems. This compatibility simplifies installations and upgrades, making it easier for businesses to enhance their measurement and control capabilities.

Applications of Diaphragm Pressure Elements

Given their numerous advantages, high-quality diaphragm pressure elements are widely used across various sectors

- Chemical Processing In chemical manufacturing, pressure monitoring is critical for ensuring safe process operations. Diaphragm pressure elements help maintain optimal pressure levels, preventing dangerous situations caused by over or under-pressurization.

- Food and Beverage In this industry, maintaining precise pressure levels can directly impact product quality and safety. Diaphragm pressure elements can help monitor pressures in processes like pasteurization, ensuring compliance with health regulations.

- Medical Devices Pressure measurement is vital in many medical devices, such as respiratory equipment and infusion pumps. High-quality diaphragm pressure elements ensure patient safety by providing accurate pressure readings, crucial in therapeutic and diagnostic applications.

- Hydraulic Systems Hydraulic machinery depends on accurate pressure measurements to function properly. High-quality diaphragm pressure elements help in controlling the hydraulic systems, leading to improved operational efficiency and safety.

Conclusion

In summary, high-quality diaphragm pressure elements play a crucial role in ensuring accurate pressure measurement and control across a wide range of industries. Their ability to deliver reliable, precise, and durable performance makes them indispensable in applications where safety and efficiency are paramount. As technology continues to evolve, the demand for advanced diaphragm pressure elements will likely increase, further underscoring the importance of quality in pressure measurement devices. By investing in high-quality elements, businesses can enhance their operational effectiveness and ensure compliance with industry standards, ultimately leading to greater success in their respective fields.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025