Feb . 17, 2025 19:35 Back to list

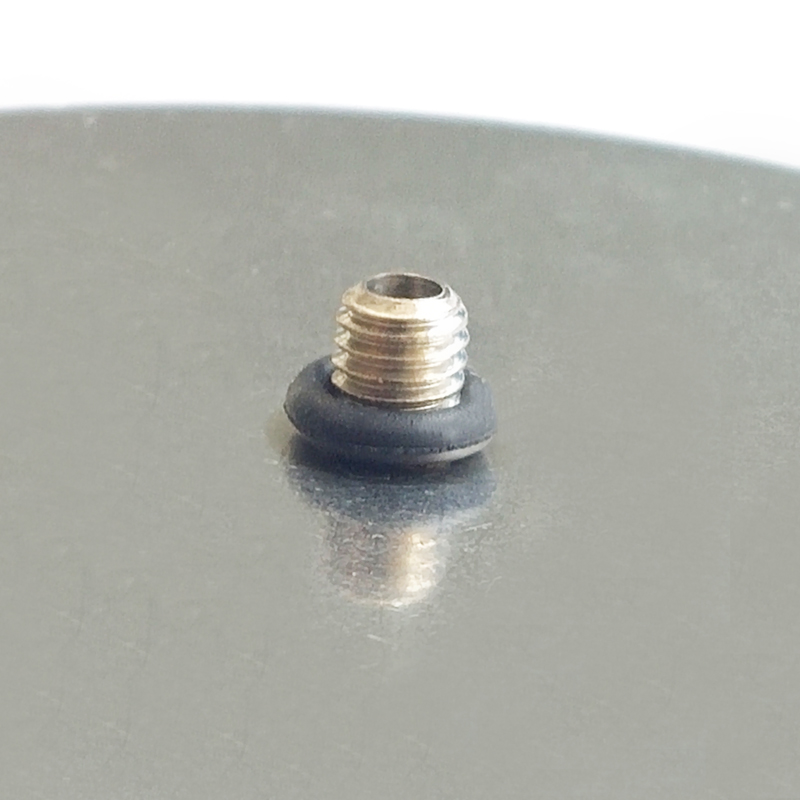

pressure diaphragm capsule element,

High-quality diaphragm pressure sensing elements have become essential components in various industrial applications where precise pressure measurements are crucial. Designed with advanced materials and innovative engineering, these sensing elements provide unmatched accuracy and reliability, making them indispensable for sectors such as pharmaceuticals, aerospace, and manufacturing.

Experts in the field emphasize the importance of choosing diaphragm pressure sensing elements from reputable manufacturers known for their adherence to stringent quality standards. These manufacturers conduct rigorous testing at every production stage, ensuring that each element can withstand the most challenging operational environments. They utilize state-of-the-art manufacturing techniques that enhance the durability and performance of the diaphragm, leading to longer lifespans and reduced maintenance costs for the end-users. Trust in high-quality diaphragm pressure sensing elements also stems from their compliance with international standards. Devices that meet or exceed standards such as ISO and ASME provide an additional layer of credibility, assuring users that these sensing elements have been evaluated and certified for performance under global benchmarks. This compliance not only enhances the element's reputation but also assures industries that they are investing in reliable and proven technology. Incorporating these sensing elements into industrial systems reflects a commitment to leveraging the best available technology. As industries increasingly prioritize efficiency and precision, the role of high-quality diaphragm pressure sensing elements has never been more critical. By ensuring accurate pressure measurements, they help optimize processes and improve system performance, leading to better outcomes and higher quality products. In summary, high-quality diaphragm pressure sensing elements represent the pinnacle of precision engineering in pressure measurement technology. Their design excellence, coupled with unwavering accuracy and reliability, make them a cornerstone for industries that cannot afford to compromise on safety and performance. Selecting these elements from trusted suppliers guarantees industries access to innovative, dependable tools that meet the demands of today's competitive environment, ensuring operational excellence and sustained success.

Experts in the field emphasize the importance of choosing diaphragm pressure sensing elements from reputable manufacturers known for their adherence to stringent quality standards. These manufacturers conduct rigorous testing at every production stage, ensuring that each element can withstand the most challenging operational environments. They utilize state-of-the-art manufacturing techniques that enhance the durability and performance of the diaphragm, leading to longer lifespans and reduced maintenance costs for the end-users. Trust in high-quality diaphragm pressure sensing elements also stems from their compliance with international standards. Devices that meet or exceed standards such as ISO and ASME provide an additional layer of credibility, assuring users that these sensing elements have been evaluated and certified for performance under global benchmarks. This compliance not only enhances the element's reputation but also assures industries that they are investing in reliable and proven technology. Incorporating these sensing elements into industrial systems reflects a commitment to leveraging the best available technology. As industries increasingly prioritize efficiency and precision, the role of high-quality diaphragm pressure sensing elements has never been more critical. By ensuring accurate pressure measurements, they help optimize processes and improve system performance, leading to better outcomes and higher quality products. In summary, high-quality diaphragm pressure sensing elements represent the pinnacle of precision engineering in pressure measurement technology. Their design excellence, coupled with unwavering accuracy and reliability, make them a cornerstone for industries that cannot afford to compromise on safety and performance. Selecting these elements from trusted suppliers guarantees industries access to innovative, dependable tools that meet the demands of today's competitive environment, ensuring operational excellence and sustained success.

Share

Latest news

-

Fire Extinguisher Pressure Gauge Manufacturers Reliable & Certified Suppliers

NewsMay.16,2025

-

Isolation Diaphragm Pressure Gauges High-Precision & Durable Solutions

NewsMay.16,2025

-

Premium Pressure Gauge Precision Instruments Reliable & Durable Solutions

NewsMay.16,2025

-

Differential Pressure Gauge Kits Precision Tools & Best Pricing

NewsMay.15,2025

-

Hydraulic Differential Pressure Gauge Accurate & Durable Industrial Solutions

NewsMay.15,2025

-

Pressure Gauges for Fire Protection Services Durable Air/Water Rated

NewsMay.15,2025