Feb . 17, 2025 20:30 Back to list

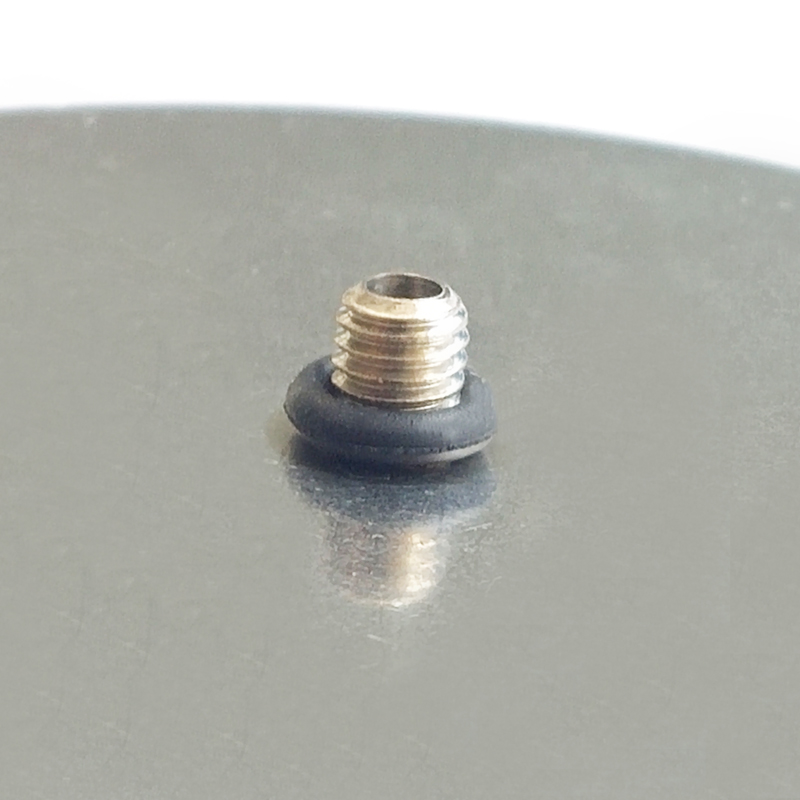

diaphragm capsule pressure gauge,

When it comes to ensuring accurate and reliable measurements in various industrial processes, the importance of choosing a high-quality diaphragm protection pressure gauge cannot be overstated. These instruments play a pivotal role in safeguarding pressure measurement systems from the damaging effects of corrosive or viscous fluids.

The evolution of smart technology has integrated pressure gauges with digital signal processing, enabling remote monitoring and diagnostics. This advancement not only increases operational efficiency but also provides predictive maintenance capabilities that greatly enhance the reliability of industrial systems. The growing adaptation of such technologies exemplifies the trajectory towards more sophisticated instrumentation solutions. Trustworthiness in diaphragm pressure gauge manufacturing is reflected through certifications and standards compliance, such as ISO 9001 for quality management systems and ATEX for equipment operating in explosive atmospheres. Ensuring these credentials not only assures the quality and safety of the product but also affirms the commitment of manufacturers to meet stringent industry standards. Lastly, maintenance and regular inspection play vital roles in the longevity and performance of diaphragm protection pressure gauges. Routine checks for signs of wear, damage to the diaphragm, or any visible leaks are critical tasks that, though often overlooked, can prevent costly downtime and ensure the continuous reliability of pressure measurement systems. In conclusion, the intricate balance of experience, expertise, authoritative insights, and trustworthiness forms the cornerstone of selecting a high-quality diaphragm protection pressure gauge. As industries continue to seek more reliable and efficient measurement solutions, these gauges stand out as exemplary tools that marry advanced technology with proven engineering, guaranteeing precision and safety across a multitude of demanding applications.

The evolution of smart technology has integrated pressure gauges with digital signal processing, enabling remote monitoring and diagnostics. This advancement not only increases operational efficiency but also provides predictive maintenance capabilities that greatly enhance the reliability of industrial systems. The growing adaptation of such technologies exemplifies the trajectory towards more sophisticated instrumentation solutions. Trustworthiness in diaphragm pressure gauge manufacturing is reflected through certifications and standards compliance, such as ISO 9001 for quality management systems and ATEX for equipment operating in explosive atmospheres. Ensuring these credentials not only assures the quality and safety of the product but also affirms the commitment of manufacturers to meet stringent industry standards. Lastly, maintenance and regular inspection play vital roles in the longevity and performance of diaphragm protection pressure gauges. Routine checks for signs of wear, damage to the diaphragm, or any visible leaks are critical tasks that, though often overlooked, can prevent costly downtime and ensure the continuous reliability of pressure measurement systems. In conclusion, the intricate balance of experience, expertise, authoritative insights, and trustworthiness forms the cornerstone of selecting a high-quality diaphragm protection pressure gauge. As industries continue to seek more reliable and efficient measurement solutions, these gauges stand out as exemplary tools that marry advanced technology with proven engineering, guaranteeing precision and safety across a multitude of demanding applications.

Share

Latest news

-

Fire Extinguisher Pressure Gauge Manufacturers Reliable & Certified Suppliers

NewsMay.16,2025

-

Isolation Diaphragm Pressure Gauges High-Precision & Durable Solutions

NewsMay.16,2025

-

Premium Pressure Gauge Precision Instruments Reliable & Durable Solutions

NewsMay.16,2025

-

Differential Pressure Gauge Kits Precision Tools & Best Pricing

NewsMay.15,2025

-

Hydraulic Differential Pressure Gauge Accurate & Durable Industrial Solutions

NewsMay.15,2025

-

Pressure Gauges for Fire Protection Services Durable Air/Water Rated

NewsMay.15,2025