Des . 07, 2024 07:05 Back to list

High Performance Diaphragm Pressure Gauge for Accurate Measurement and Reliability

The Importance of High-Quality Diaphragm Pressure Gauges

In various industrial and scientific applications, pressure measurement is paramount for ensuring safety, efficiency, and reliability. Among the tools available for this purpose, the diaphragm pressure gauge stands out as a particularly effective solution. Characterized by its use of a flexible diaphragm to sense pressure changes, these gauges offer superior performance compared to traditional mechanical pressure measuring devices. The focus on high-quality diaphragm pressure gauges has grown significantly, as they provide enhanced accuracy, durability, and overall functionality.

Understanding Diaphragm Pressure Gauges

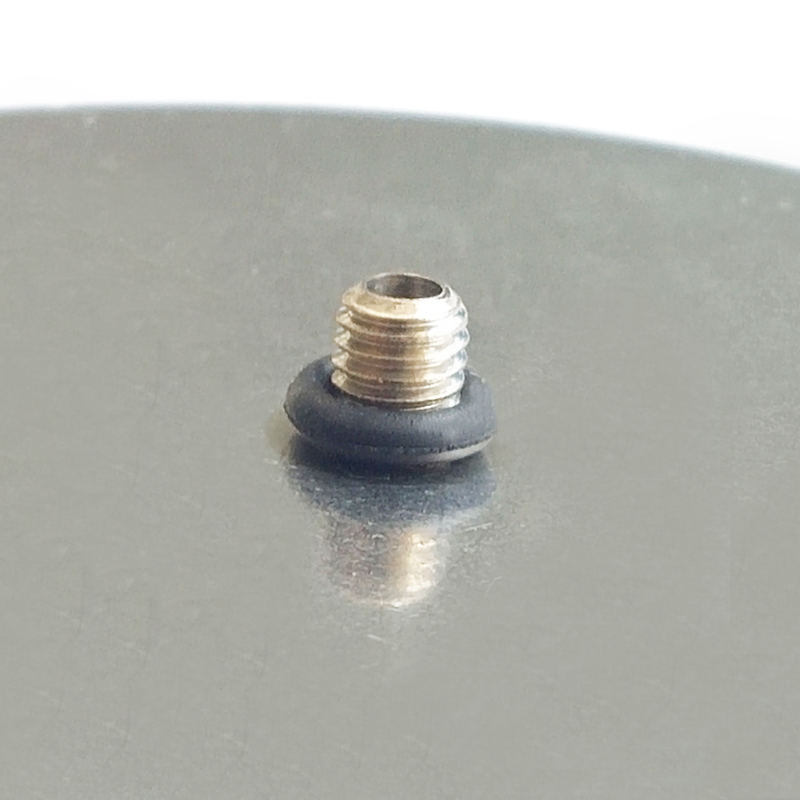

Diaphragm pressure gauges consist of a thin, flexible membrane that deforms in response to pressure changes. This deformation translates into a measurable displacement, which is then converted into a pressure reading. The diaphragm itself can be made from various materials depending on the application, such as stainless steel, brass, or elastomers, which helps to ensure compatibility with the medium being measured, whether it be gas, liquid, or steam.

Advantages of High-Quality Gauges

1. Accuracy and Precision One of the most critical factors in pressure measurement is accuracy. High-quality diaphragm gauges are designed to provide precise readings, typically within a narrow margin of error. This accuracy is essential in processes where exact pressure levels are critical, such as in chemical manufacturing or pharmaceutical production. The use of advanced manufacturing techniques and high-grade materials ensures stability and minimal hysteresis in readings.

2. Durability and Reliability Industrial environments can be harsh, with factors such as temperature fluctuations, vibration, and corrosive substances posing risks to measuring instruments. High-quality diaphragm pressure gauges are constructed to withstand these conditions, thereby enhancing their lifespan and reliability. The materials used for diaphragm construction are often resistant to corrosion, wear, and fatigue, making them suitable for long-term use.

high quality the diaphragm pressure gauge

3. Versatility Another significant advantage of diaphragm pressure gauges is their versatility. They can be used in a variety of applications, from monitoring the pressure of gases and liquids to measuring the pressure in sealed systems. Their ability to handle a wide range of pressures and environmental conditions further underscores their utility in numerous industries, including oil and gas, food and beverage, and HVAC.

4. Low Maintenance Requirements High-quality diaphragm gauges are often designed for low maintenance. Many models feature hermetically sealed designs that prevent dust and moisture ingress, reducing the need for frequent calibration or cleaning. This aspect is particularly beneficial in maintaining operational efficiency, as it minimizes downtime associated with equipment maintenance.

5. Enhanced Safety In many industries, inaccurate pressure readings can lead to catastrophic failures, making safety a top concern. High-quality diaphragm pressure gauges are integral to monitoring and controlling systems effectively, thus helping to prevent overpressure situations that could result in explosions or leaks. The reliability of these gauges contributes to a safer working environment for personnel and surrounding communities.

Conclusion

As industries strive for greater efficiency, accuracy, and safety in their operations, the demand for high-quality diaphragm pressure gauges continues to rise. Their ability to provide precise readings, coupled with durability and versatility, positions them as a critical component in modern pressure measurement applications. Investing in high-quality diaphragm pressure gauges not only enhances operational effectiveness but also ensures compliance with safety regulations and standards.

In summary, the significance of choosing high-quality diaphragm pressure gauges cannot be overstated. They offer a robust solution for accurate and reliable pressure measurement in a multitude of applications. By prioritizing quality in the selection of these instruments, companies can foster safe, efficient, and productive work environments, ultimately leading to increased operational success.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025