Des . 20, 2024 12:24 Back to list

metal diaphragm type pressure gauges suppliers

Metal Diaphragm Type Pressure Gauges An Overview for Suppliers

In the realm of industrial instrumentation, pressure gauges play a critical role in monitoring and controlling processes across various sectors. Among the different types of pressure measurement devices, metal diaphragm type pressure gauges have gained popularity due to their durability, reliability, and accurate performance in hostile environments. This article delves into the workings, advantages, and suppliers of metal diaphragm type pressure gauges.

Understanding Metal Diaphragm Pressure Gauges

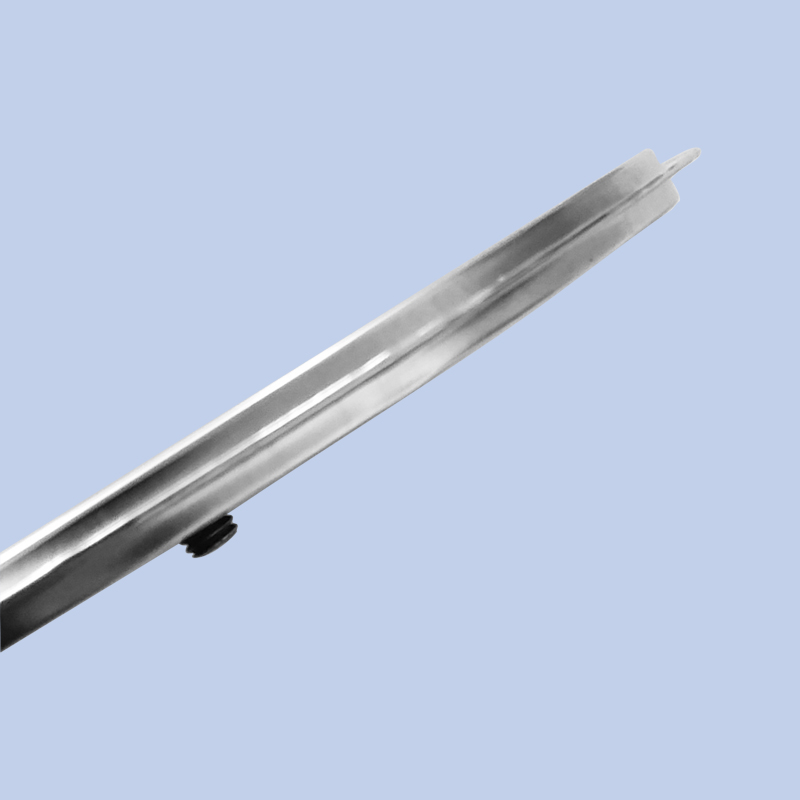

Metal diaphragm pressure gauges utilize a flexible metallic diaphragm as the sensing element to measure pressure. When pressure is applied, the diaphragm deflects, and this displacement is converted into a readable output, usually displayed on a dial or digital readout. These gauges can measure various types of pressures, including absolute, gauge, and differential pressures.

The construction of metal diaphragm pressure gauges involves high-quality materials like stainless steel, which provides excellent resistance to corrosion and temperature fluctuations. This robust design makes them suitable for demanding applications, including those in the oil and gas industry, pharmaceuticals, food processing, and chemical manufacturing.

Advantages of Metal Diaphragm Pressure Gauges

1. Durability and Longevity Metal diaphragm gauges are known for their ability to withstand harsh conditions, including extreme temperatures and high-pressure environments. The robust construction ensures that these gauges have a lengthy lifecycle, reducing the need for frequent replacements.

2. Versatile Applications These gauges can be used for a variety of media, including gases, liquids, and vapors. Their adaptability makes them an ideal choice for different industries, accommodating a wide range of process requirements.

3. High Accuracy Metal diaphragm pressure gauges provide precise pressure readings, which are crucial for maintaining safety and efficiency in industrial processes. The minimal wear and tear on the diaphragm contribute to consistent performance.

4. Minimal Maintenance With fewer moving parts compared to traditional liquid-filled gauges, metal diaphragm gauges require less maintenance. This feature is particularly beneficial in remote or hazardous locations where routine maintenance can be challenging.

metal diaphragm type pressure gauges suppliers

5. Compact Design Their smaller size and lightweight nature make metal diaphragm gauges easy to install in various setups, particularly in tight spaces where traditional gauges may not fit.

Choosing the Right Supplier

When it comes to sourcing metal diaphragm pressure gauges, selecting the right supplier is crucial for ensuring quality and reliability. Here are some factors to consider

1. Reputation Look for suppliers with a proven track record in the industry. Reading reviews and testimonials from other clients can provide valuable insights into the supplier’s product quality and customer service.

2. Product Range A reputable supplier should offer a wide array of products to cater to different industrial needs. This varies from gauges with different pressure ranges to those made for specific environments.

3. Certifications Ensure that the supplier’s products meet necessary industry standards and certifications. This ensures that the gauges are made with quality materials and adhere to safety protocols.

4. Technical Support Good suppliers often provide technical assistance and support, which can be essential during installation, calibration, and maintenance of the pressure gauges.

5. After-sales Service Opt for suppliers who offer warranty and after-sales service. This builds confidence in the quality of the products and assures the availability of assistance if issues arise.

Conclusion

Metal diaphragm type pressure gauges are an integral part of many industrial processes, offering durability, accuracy, and versatility. As industries continue to evolve, the demand for such high-performance instruments will likely increase. Suppliers play a vital role in matching the needs of industries with quality products, making it imperative for industry players to choose their partners wisely. By considering factors like reputation, product range, and support services, businesses can ensure they are equipped with the best tools for maintaining smooth operations. In an ever-competitive landscape, a reliable pressure gauge can make a significant difference in operational efficiency and safety.

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025

-

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

NewsMay.23,2025

-

Industrial Differential Pressure Gauges Global Supplier & Pricelist

NewsMay.23,2025

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025