Nov . 30, 2024 09:55 Back to list

Leading Manufacturers of Precision Instrumentation and Pressure Gauges for Accurate Measurements

Precision Instruments in Pressure Gauges Manufacturing

In the ever-evolving realm of industrial instrumentation, precision instruments play a pivotal role, particularly in the manufacturing of pressure gauges. Pressure gauges are essential tools used across various industries, providing critical measurements that ensure operational safety and efficiency. From oil and gas to pharmaceuticals, the demand for precision in pressure measurement cannot be overstated.

The Importance of Precision

In industries where pressure control is non-negotiable, even the slightest deviation in measurement can lead to catastrophic consequences. For instance, in the oil and gas sector, accurate pressure measurements are vital for the safe extraction and transportation of crude oil and natural gas. In pharmaceuticals, precise pressure readings are essential to maintain the integrity of sensitive chemical processes. Manufacturers of pressure gauges must therefore prioritize precision in their designs and production methods.

Advanced Manufacturing Techniques

Pressure gauge manufacturers have adopted advanced manufacturing techniques to enhance precision. Computer Numerical Control (CNC) machining, for example, allows for the creation of components with extreme accuracy. CNC machines can produce intricate parts that meet tight tolerances, ensuring that the gauges maintain their reliability under varying conditions.

Additionally, the use of automation in assembly processes minimizes human error, further enhancing the precision of the final product. Automation provides consistency and accuracy, allowing for mass production without sacrificing quality. Furthermore, advanced calibration methods help ensure that each gauge is finely tuned before it reaches the market, solidifying the manufacturer's commitment to precision.

Material Selection

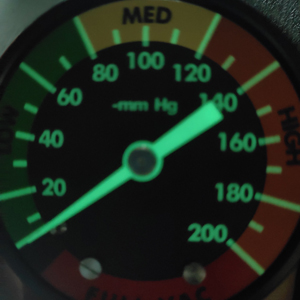

precision instruments pressure gauges manufacturers

The materials used in pressure gauge manufacturing also contribute significantly to precision. High-quality materials that can withstand extreme temperatures and pressures are paramount. Stainless steel and other high-grade alloys are commonly employed due to their durability and resistance to corrosion. These materials not only enhance the performance of the gauges but also extend their lifespan, which is crucial for maintaining operational reliability.

Technological Advancements

The industry has seen a surge in technological advancements that further improve the accuracy of pressure gauges. Digital pressure gauges, for instance, offer superior precision compared to traditional analog models. Equipped with advanced sensors and microprocessors, these gauges provide real-time data with high resolution. This technology allows for easier interpretation of results and enables predictive maintenance, which can prevent unexpected failures.

Moreover, the integration of IoT (Internet of Things) technologies has transformed pressure monitoring. Smart pressure gauges can relay data to centralized systems, allowing for continuous monitoring and analysis. This real-time data collection is invaluable for industries that require immediate responses to pressure changes, thus enhancing operational safety.

Quality Control

Quality control is another critical aspect of pressure gauge manufacturing. Manufacturers implement rigorous testing procedures to verify the accuracy and reliability of their products. This includes pressure testing, where gauges are subjected to various pressure levels to ensure they respond accurately. Continuous improvement of quality control processes is essential for maintaining high standards in production, which in turn assures customers of the precision and reliability of the gauges they purchase.

Conclusion

In conclusion, the manufacturing of pressure gauges is a testament to the significance of precision in industrial instrumentation. As industries continue to advance and demand for accuracy grows, manufacturers must invest in advanced technologies, robust materials, and stringent quality control measures. By doing so, they can produce pressure gauges that not only meet but exceed industry standards, ensuring safety and efficiency across various applications. As we move forward, the focus on precision in pressure gauge manufacturing will remain a cornerstone for innovation and reliability in the industrial sector.

-

Fluke Differential Pressure Gauges Precision Instruments for Industrial Use

NewsMay.25,2025

-

WIKA Differential Pressure Gauge 700.01 - High Accuracy & Durable Design

NewsMay.25,2025

-

Diaphragm Pressure Gauges High-Accuracy & Durable Solutions

NewsMay.25,2025

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025