Set . 07, 2024 08:44 Back to list

Barton Differential Pressure Gauge Exporters - Precision Measurement Solutions

The Role of Barton Differential Pressure Gauges in Industry

In the realm of industrial measurement and instrumentation, the demand for accurate and reliable devices is paramount. Among these, Barton differential pressure gauges stand out as essential tools in various sectors, including oil and gas, pharmaceuticals, and HVAC systems. These gauges are designed to measure the difference in pressure between two points in a system, providing critical insights that can help operators maintain efficiency and safety.

Barton differential pressure gauges are renowned for their robust construction and precise measurement capabilities. Made from high-quality materials, these gauges can withstand harsh environments and extreme conditions, making them suitable for demanding applications. Whether monitoring pressure in pipelines, tanks, or filtration systems, these gauges deliver accurate readings that are vital for maintaining the integrity of the process.

One of the key advantages of Barton differential pressure gauges is their versatility. They are available in a variety of styles and specifications, allowing them to be tailored to specific industry needs. For instance, models can vary based on pressure ranges, mounting options, and connection sizes, ensuring that every application is covered. This adaptability is critical in industries where precise pressure management can affect product quality and operational efficiency.

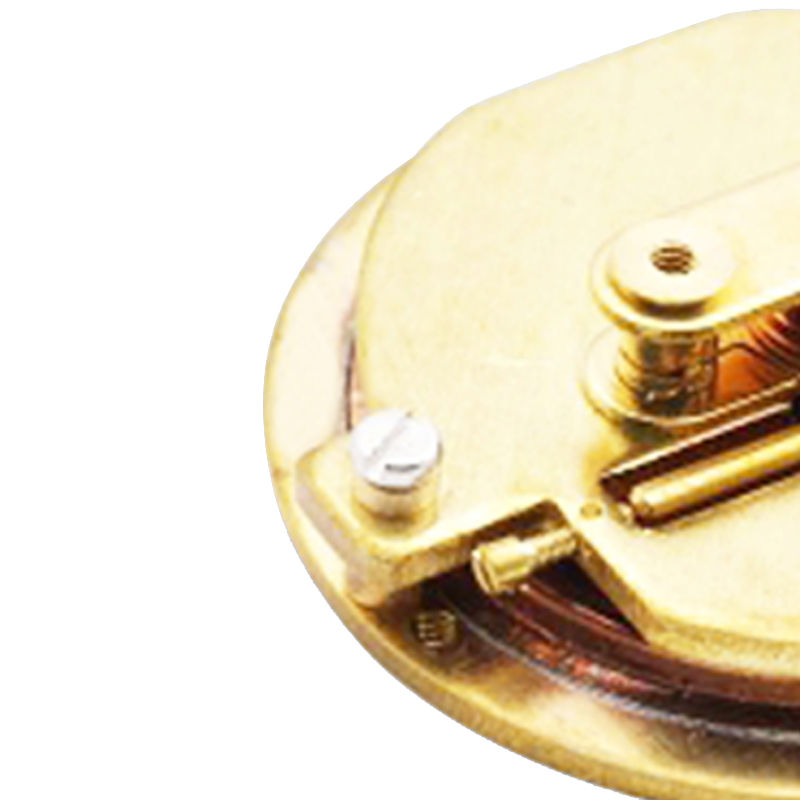

barton differential pressure gauge exporters

The export of Barton differential pressure gauges has seen a significant rise in recent years, reflecting the growing global demand for high-quality measurement instruments. Manufacturers are increasingly focusing on optimizing their production processes to meet this demand, ensuring that they uphold the high standards associated with the Barton brand. This global outreach not only helps in expanding market share but also fosters innovation and improvement in product design and functionality.

In addition to their practical applications, Barton differential pressure gauges are also valued for their ease of installation and maintenance. Many models feature user-friendly designs that allow for quick installation and minimal downtime during maintenance. This is particularly important for industries where any disruption can lead to significant financial losses.

Furthermore, the integration of advanced technologies into these gauges is paving the way for smarter operational strategies. With the advent of digital pressure gauges, data logging, and remote monitoring capabilities, operators can now obtain real-time data that enhances decision-making processes. This advancement reflects a broader trend in industrial measurements, where digital solutions are transforming traditional practices.

In conclusion, Barton differential pressure gauges are indispensable instruments in various industrial applications. Their reliability, versatility, and evolving technology make them a preferred choice for many organizations worldwide. As the demand for these gauges continues to grow in the global market, so too does the commitment of manufacturers to innovate and deliver products that meet the highest standards of excellence. Investing in such technology not only enhances operational efficiency but also contributes to safer and more effective industrial practices.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025