Dic . 04, 2024 07:14 Back to list

China's Advanced Digital Precision Pressure Measurement Technology and Applications

Understanding China’s Digital Precision Pressure Gauge Technology

In today’s rapidly advancing technological landscape, instrumentation and measurement tools play a critical role across various industries. Among these, digital precision pressure gauges have gained significant prominence, particularly in China, reflecting the country's commitment to high-quality manufacturing and innovative solutions. This article delves into the features, applications, and benefits of digital precision pressure gauges, as well as the implications of China’s advancement in this field.

What is a Digital Precision Pressure Gauge?

A digital precision pressure gauge is an electronic instrument used to measure fluid or gas pressure precisely. Unlike traditional analog gauges, which rely on mechanical components to display pressure readings, digital gauges utilize electronic sensors and digital displays. This transition to digital technology allows for enhanced accuracy, ease of reading, and additional functionalities.

Features of Digital Precision Pressure Gauges

1. High Accuracy and Sensitivity Digital pressure gauges typically offer better accuracy levels, often up to ±0.1% of the full scale. This high precision is essential for processes where pressure measurements need to be exact, such as in pharmaceuticals and aerospace industries.

2. Easy Readability The digital display eliminates the difficulty of interpreting needle positions on analog gauges. Users can easily read the pressure values, often supplemented with features like backlighting for visibility in low-light conditions.

3. Data Logging and Connectivity Modern digital gauges can store measurements, which can be invaluable for tracking trends over time. Many models also offer connectivity options via Bluetooth or Wi-Fi, allowing for real-time data transfer to computers or smartphones for further analysis.

4. Robust Design Many digital pressure gauges designed in China are built to withstand harsh environments, including extreme temperatures and corrosive conditions. They are often designed to meet international standards, ensuring reliability in various applications.

5. Customization and Versatility Chinese manufacturers provide a wide range of models tailored for different industries, allowing for customization based on the specific needs of users. This versatility makes them suitable for applications ranging from HVAC systems to food processing.

Applications of Digital Precision Pressure Gauges

Digital precision pressure gauges are employed across numerous sectors, reflecting their versatility and reliability

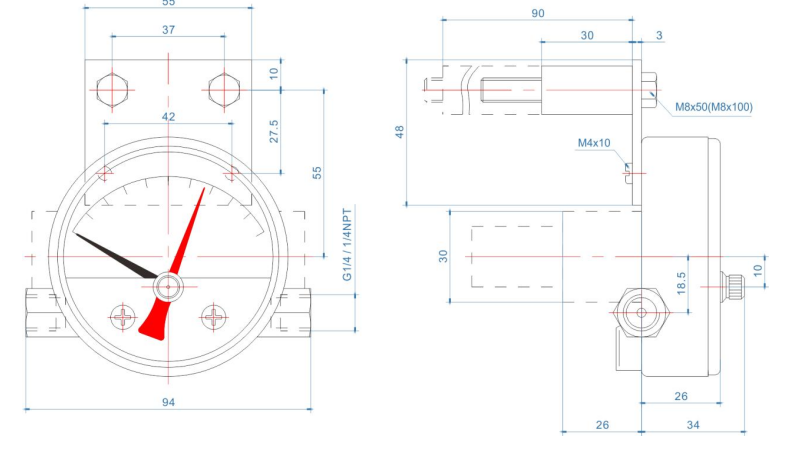

china digital precision pressure gauge

- Manufacturing In manufacturing processes, maintaining precise pressure levels is crucial for product quality

. Digital gauges help monitor and control pressure in systems involving fluids and gases.- Oil and Gas Within the oil and gas industry, pressure measurements are vital for safety and operational efficiency. Digital gauges enable monitoring of pipeline pressures, tank levels, and various other critical parameters.

- Medical and Pharmaceutical Accuracy is paramount in healthcare settings, where digital pressure gauges are used in pressure chambers, oxygen delivery systems, and more. They contribute significantly to ensuring patient safety and treatment efficacy.

- Automotive In automotive applications, these gauges help in monitoring tire pressure and evaluating engine performance metrics, promoting both safety and efficiency.

Benefits of Embracing Digital Precision Pressure Gauges

1. Increased Efficiency The rapid and accurate measurements provided by digital gauges facilitate smoother operations, reducing downtime caused by pressure-related issues.

2. Enhanced Safety By offering real-time monitoring and alerts, digital pressure gauges contribute to safer operational environments, allowing for prompt responses to pressure fluctuations.

3. Cost-Effective Solutions Although the initial investment in digital technology may be higher than traditional gauges, the long-term benefits—including reduced maintenance and increased efficiency—often offset these costs.

4. Support for Industry 4.0 Digital gauges are integral to connecting machinery and equipment to data analytics systems in the context of Industry 4.0. They support automation and smart manufacturing initiatives by providing crucial real-time data.

Conclusion

China’s advancements in digital precision pressure gauge technology highlight the nation’s dedication to improving industrial instrumentation. With high accuracy, robust design, and versatile applications, digital pressure gauges are becoming indispensable tools in modern industry. As technology continues to evolve, these instruments are poised to play an even greater role in enhancing efficiency, safety, and productivity across diverse sectors. Embracing such innovations is essential for businesses aiming to thrive in a competitive global market.

-

Fluke Differential Pressure Gauges Precision Instruments for Industrial Use

NewsMay.25,2025

-

WIKA Differential Pressure Gauge 700.01 - High Accuracy & Durable Design

NewsMay.25,2025

-

Diaphragm Pressure Gauges High-Accuracy & Durable Solutions

NewsMay.25,2025

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025