Dic . 11, 2024 12:55 Back to list

Custom Differential Pressure Gauges Supplier with Diverse Applications and Solutions for Your Needs

Custom Differential Pressure Gauges Distributor Meeting Diverse Industry Needs

In an era where accuracy and reliability are paramount in industrial operations, differential pressure gauges have become indispensable instruments. These devices measure the difference in pressure between two points, providing critical data for various applications in industries such as HVAC, water treatment, oil and gas, and pharmaceuticals. The demand for custom differential pressure gauges is increasing, leading to a growing market for specialized distributors who can cater to unique specifications and requirements.

Understanding Differential Pressure Gauges

Differential pressure gauges are designed to monitor pressure differences within a system. They operate by utilizing two pressure ports; one measures the pressure of a certain point while the other gauge measures another point. The difference between these readings can indicate various system parameters, such as flow rates, filter conditions, and equipment performance. This capability makes them vital for maintaining optimal conditions in processes and ensuring safety standards are met.

The Role of Customization

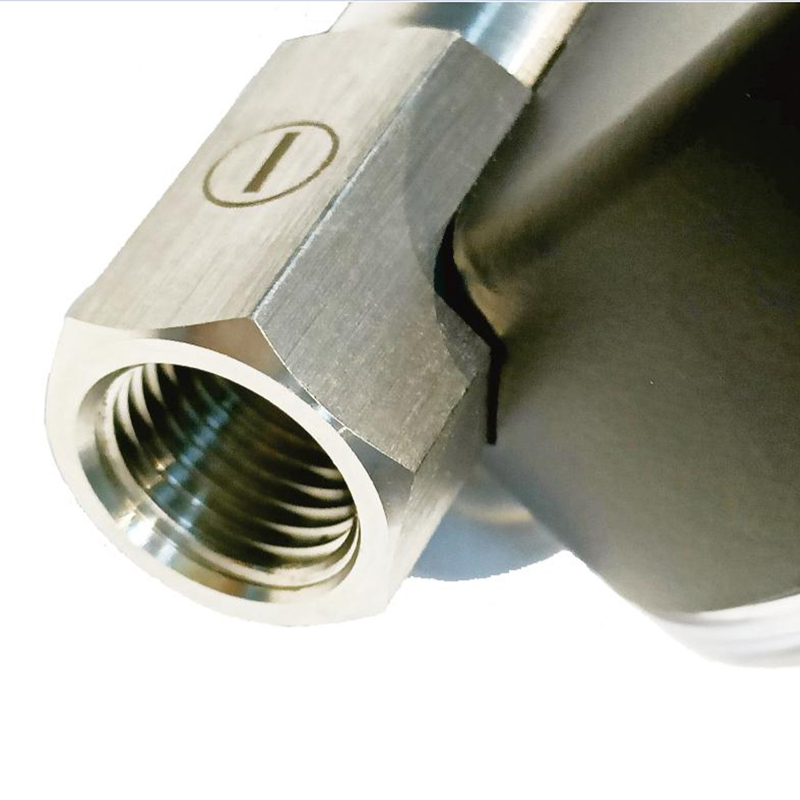

Many sectors require specific features and attributes from their measurement tools. Custom differential pressure gauges can be tailored regarding size, construction materials, pressure range, and even display types. For instance, in corrosive environments, a manufacturer might opt for materials like stainless steel or special alloys to prevent degradation. Similarly, industries with rigorous sanitation standards, such as pharmaceuticals, may require gauges that are easy to clean and meet stringent hygiene regulations.

Distributors specializing in custom gauges ensure that clients receive products that perfectly fit their systems and operational concerns. These distributors work closely with clients to understand their applications and challenges, recommending the most suitable configurations that will enhance performance and efficiency.

Selecting a Reliable Distributor

Choosing the right distributor for custom differential pressure gauges involves careful consideration. Here are a few key factors to take into account

1. Industry Expertise A distributor should have extensive knowledge of the specific industries they serve. This level of expertise allows them to provide tailored advice and solutions.

custom differential pressure gauges distributor

2. Quality Assurance Quality control is crucial in manufacturing pressure gauges. Distributors should represent brands that follow stringent quality assurance protocols and possess the necessary certifications, such as ISO or AGA.

3. Technical Support A knowledgeable distributor will offer technical support to help clients install, operate, and maintain their custom gauges. This support can be invaluable in preventing downtime and ensuring accuracy in measurements.

4. Responsive Service Timely responses to inquiries and an understanding of the urgency in various industrial applications are essential qualities in a distributor.

5. Comprehensive Inventory A well-stocked distributor can offer a range of differential pressure gauges and related accessories. They should also have the capability to manufacture custom orders efficiently, reducing lead times for specialized products.

The Future of Differential Pressure Gauges

As industries evolve, the need for enhanced monitoring and control continues to grow. Innovations in technology, such as digital displays, wireless connectivity, and advanced materials, are shaping the future of differential pressure measurements. Distributors who keep pace with these advancements will provide significant value to their clients.

Moreover, with growing emphasis on industrial automation and data analytics, integrating differential pressure gauges with smart systems will allow for real-time monitoring and predictive maintenance capabilities. Distributors partaking in these developments will help their clients make better-informed decisions, driving efficiency and cost savings.

Conclusion

In conclusion, the role of custom differential pressure gauges and their distributors is crucial in ensuring operational excellence across various industries. By choosing the right distributor that offers tailored solutions, quality products, and expert support, businesses can enhance their monitoring capabilities and maintain stringent standards in their operations. The future promises exciting advancements in this area, making it an opportune time to invest in custom differential pressure gauges that meet the unique needs of each application.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025