Set . 28, 2024 17:43 Back to list

Tailored Diaphragm Seal Pressure Gauge Solutions for Optimal Performance and Reliability

Customized Diaphragm Seal Pressure Gauge Products Enhancing Measurement Precision in Challenging Environments

In today’s industrial landscape, the need for precise and reliable pressure measurement has become increasingly crucial. Various sectors, including oil and gas, chemical processing, pharmaceuticals, and food and beverage, require instruments that can withstand harsh conditions while maintaining accuracy. Customized diaphragm seal pressure gauge products have emerged as a solution to these demanding requirements, offering specialized features that enhance performance and reliability.

Understanding Diaphragm Seal Pressure Gauges

A diaphragm seal pressure gauge operates by isolating the pressure measurement element from the process media using a flexible diaphragm. This design is particularly beneficial in scenarios where the fluid being measured is corrosive, viscous, or contains particulate matter. The diaphragm effectively protects the measurement element, extending the lifespan of the gauge and ensuring accurate readings.

The customization of diaphragm seal pressure gauges allows manufacturers to modify various aspects, including materials, sizes, and configurations, to meet specific application needs. For instance, industries processing highly corrosive chemicals may require components made from exotic alloys or materials resistant to chemical attacks, such as PTFE or Hastelloy. Similarly, applications involving high-temperature processes might necessitate gauges designed to handle significant thermal variations.

Benefits of Customized Solutions

1. Enhanced Accuracy and Performance Customized diaphragm seals can be tailored to align perfectly with the process conditions, ensuring that the pressure readings are accurate. Since the diaphragm is specifically designed for the type of media and pressure levels encountered in the application, there is a reduced risk of measurement errors due to media interference.

2. Protection Against Contamination In applications where cleanliness is paramount, such as in the pharmaceutical and food industries, the design customizations can include ensuring that the diaphragm seal effectively prevents contamination. The minimal dead space helps in avoiding residue build-up, thereby improving hygiene and compliance with industry regulations.

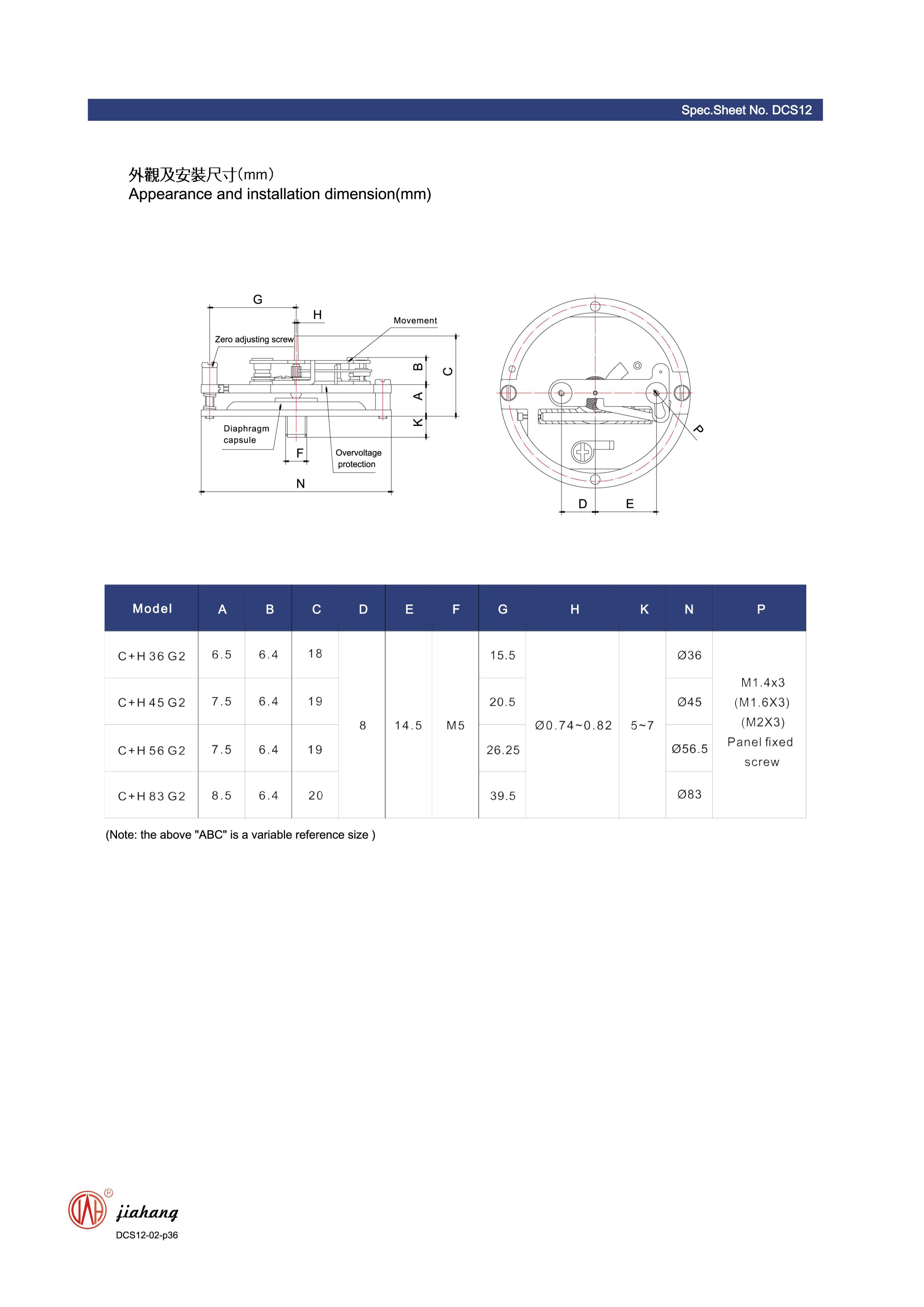

customized diaphragm seal pressure gauge products

3. Ability to Handle Extreme Conditions Customized diaphragm seal pressure gauges can be designed to operate in extreme temperatures and pressures. This makes them suitable for use in varied environments, from high-pressure industrial settings to high-temperature applications in steam processes.

4. Improved Longevity and Reliability By selecting specific materials and designs that cater to the operating environment, customized diaphragm gauges tend to have a longer lifespan. This reduces the need for frequent replacement, thereby saving costs in the long run and minimizing downtime in production processes.

5. Flexibility in Application Customization opens the possibility of using diaphragm seal pressure gauges in non-standard applications. For example, in applications with specific mounting requirements or in unusual geometries, tailored designs can ensure that the gauges fit perfectly, thus optimizing their functionality.

Implementation and Considerations

When considering customized diaphragm seal pressure gauges, it’s essential for companies to engage closely with manufacturers or suppliers. Detailed discussions about the specific application requirements, including media types, temperature ranges, pressure limits, and environmental conditions, can help in the design process.

Additionally, it’s advisable to request samples or prototypes to evaluate the performance of the customized gauges in real-time conditions before committing to large orders. Collaboration with experienced engineers can also enhance the effectiveness of the selection process, ensuring that the final product not only meets but exceeds expectations.

Conclusion

Customized diaphragm seal pressure gauge products represent a vital component for industries demanding high levels of precision under challenging conditions. Their ability to provide accurate measurements while offering protection against adverse media makes them indispensable tools in various applications. As industries continue to evolve, the customization of these gauges will likely play an increasingly pivotal role in enhancing operational efficiency and reliability, demonstrating that tailored solutions truly make a difference in the world of pressure measurement.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025