Nov . 08, 2024 22:04 Back to list

custom parker differential pressure gauge

Understanding Custom Parker Differential Pressure Gauges An In-Depth Look

In the realm of industrial instrumentation, differential pressure gauges play a crucial role in monitoring and controlling processes. Among the leading manufacturers of such instruments is Parker, a company well-known for its commitment to quality and innovation. This article delves into the specifics of custom Parker differential pressure gauges, exploring their design, applications, and advantages.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument used to measure the difference in pressure between two points. This difference can indicate various conditions in systems such as filtration, pumping, and HVAC systems. By providing a direct reading of pressure differences, these gauges allow operators to monitor system performance, detect system anomalies, and ensure optimal functioning.

The Importance of Customization

While standard differential pressure gauges serve many applications, custom gauges can provide tailored solutions that meet specific requirements of various industries. Customization in Parker differential pressure gauges often involves adjusting parameters such as gauge range, materials, connections, mounting options, and display formats.

Applications of Custom Parker Differential Pressure Gauges

Custom Parker differential pressure gauges are utilized across different sectors

1. Oil and Gas In the oil and gas industry, differential pressure gauges are essential for monitoring filters, separators, and flow restrictions. Custom gauges can be designed to withstand harsh environments and corrosive chemicals.

2. Water Treatment Water treatment plants use differential pressure gauges to monitor filtration processes, ensuring clean water production. Custom gauges enable precise measurements that influence operational efficiency.

3. HVAC Systems In heating, ventilation, and air conditioning systems, these gauges help maintain airflow by measuring the pressure difference across filters and ducts. Custom solutions can integrate seamlessly with existing systems.

4. Pharmaceuticals In the pharmaceutical industry, maintaining sterile environments is critical. Custom differential pressure gauges help monitor the integrity of clean rooms and controlled environments.

5. Food and Beverage The food industry relies on these gauges for monitoring processes like filtration and carbonation. Custom designs ensure that the gauges can handle the specific conditions of food production.

Key Features of Custom Parker Differential Pressure Gauges

custom parker differential pressure gauge

1. Material Selection Custom gauges can be made from various materials such as stainless steel, brass, or plastic, allowing them to resist corrosion and wear in specific environments.

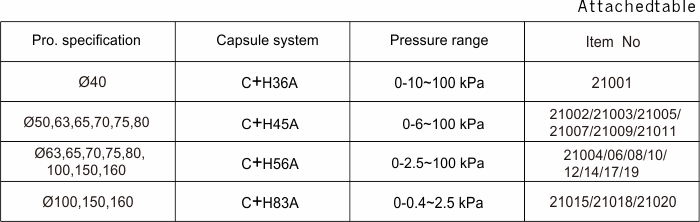

2. Pressure Range Custom gauges can be calibrated for specific pressure ranges, making them suitable for low-pressure applications or high-pressure scenarios, depending on the industry needs.

3. Connection Options Different industries may require various connection types. Custom Parker differential pressure gauges can be equipped with threaded, flanged, or sanitary connections to fit specific installation requirements.

4. Display Options Customization also allows for different display styles, including dial, digital readouts, or even remote monitoring capabilities that enhance usability and data acquisition.

5. Temperature Tolerance In processes that involve extreme temperatures, gauges can be tailored to withstand high thermal stress, ensuring accurate readings no matter the operating conditions.

Advantages of Using Custom Parker Differential Pressure Gauges

1. Precision Custom gauges are built to meet specific application demands, providing accurate and reliable data essential for operational success.

2. Durability With materials and designs tailored to specific environments, custom differential pressure gauges are more durable, reducing maintenance needs and downtime.

3. Enhanced Performance By using gauges that are specifically designed for particular applications, industries can optimize their processes, leading to better efficiency and productivity.

4. Improved Safety Monitoring pressure differences accurately helps to prevent system failures or accidents, ensuring a safer working environment.

5. Cost-Effectiveness Although custom solutions may have a higher upfront cost, the long-term benefits of reduced maintenance, downtime, and improved efficiency can lead to significant savings.

Conclusion

Custom Parker differential pressure gauges represent a blend of engineering excellence and adaptable design. By addressing the unique needs of various industries, these gauges enhance operational effectiveness, safety, and reliability. For businesses operating in demanding environments, investing in bespoke differential pressure gauges leads to better process management and improved outcomes, making them an essential tool in industrial instrumentation.

-

Fluke Differential Pressure Gauges Precision Instruments for Industrial Use

NewsMay.25,2025

-

WIKA Differential Pressure Gauge 700.01 - High Accuracy & Durable Design

NewsMay.25,2025

-

Diaphragm Pressure Gauges High-Accuracy & Durable Solutions

NewsMay.25,2025

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025