Set . 22, 2024 02:44 Back to list

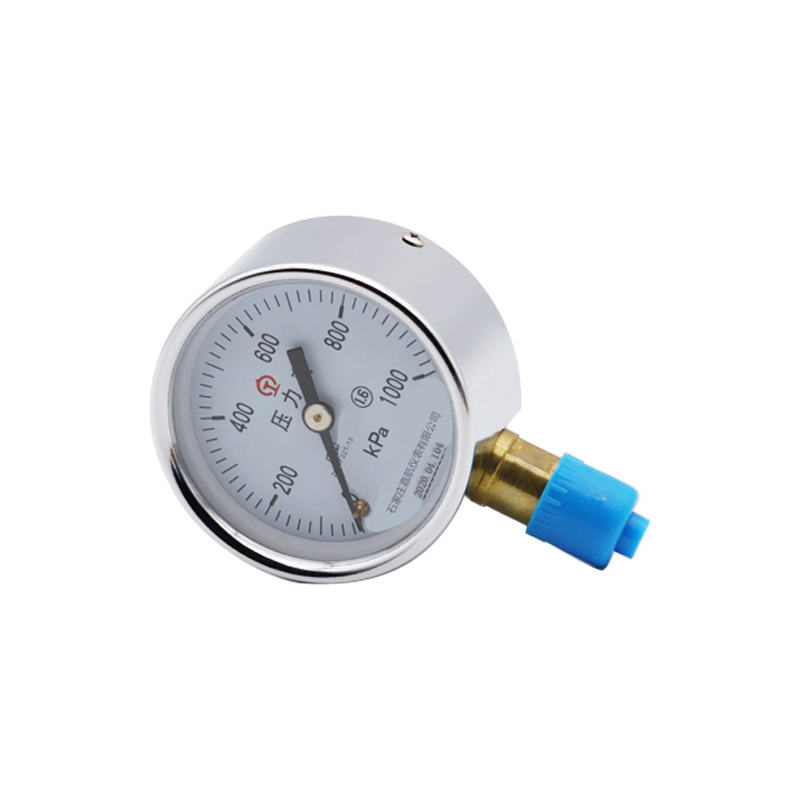

diaphragm type pressure gauges factory

Diaphragm Type Pressure Gauges A Comprehensive Overview

Diaphragm type pressure gauges are essential instruments used in various industrial applications to measure the pressure of gases and liquids. Their design enables accurate readings while maintaining operational integrity even in challenging environments. This article will explore the features, advantages, and applications of diaphragm-type pressure gauges, highlighting why they are a preferred choice in many industries.

At the core of diaphragm type pressure gauges is the diaphragm itself, which is a flexible membrane typically made from materials such as stainless steel or elastomers. When pressure is applied, the diaphragm deflects, translating pressure into mechanical movement. This movement drives the gauge's pointer to indicate the pressure level on a dial or digital display. The design can be adapted to handle different ranges of pressure, making these gauges versatile tools for monitoring systems.

One of the primary advantages of diaphragm type pressure gauges is their ability to handle fluctuating pressure conditions. Their construction allows them to withstand pulsation and vibration, which can often lead to inaccurate readings in other types of pressure measurement devices. Additionally, the diaphragm isolates the measuring mechanism from the medium being measured, reducing the risk of damage and contamination, making these gauges ideal for harsh environments.

diaphragm type pressure gauges factory

Diaphragm type pressure gauges are widely used in various industries including chemical processing, oil and gas, food and beverage, and pharmaceuticals. In chemical processing, for example, these gauges are essential for ensuring that processes remain within safe pressure limits, helping to prevent potentially hazardous situations. Similarly, in the food and beverage industry, they monitor pressure during production processes to ensure product quality and adherence to safety standards.

Besides their reliability and accuracy, diaphragm type pressure gauges are also customizable. They can be fitted with different mounting options, such as back or side connections, and can be equipped with additional features like transmitters or electrical outputs for automated systems. As such, these gauges can easily integrate into existing systems, enhancing operational efficiency.

In conclusion, diaphragm type pressure gauges are indispensable tools across a multitude of sectors, providing accurate and reliable pressure readings. Their unique design and robust construction make them well-suited for various applications, ensuring safety and efficiency. As industries continue to evolve, the demand for precise pressure measurement will only grow, further solidifying the role of diaphragm type pressure gauges in industrial applications. Their versatility and resilience make them an essential instrument in any operation requiring thorough pressure management.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025