Nov . 27, 2024 15:50 Back to list

Manufacturers of Differential Pressure Gauges with 1 2 NPT Connections and Specifications

Understanding Differential Pressure Gauges An Insight into NPT Factories

In industrial settings, where precise measurement of pressure is critical, differential pressure gauges play a vital role. Often used in a variety of applications, these instruments measure the difference in pressure between two points, providing valuable data for monitoring system performance and ensuring safety. This article delves into differential pressure gauges, especially focusing on those manufactured in factories using National Pipe Taper (NPT) standards.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument designed to measure pressure differences between two locations in a system. The gauge can indicate whether there is a buildup of pressure, which can be crucial in processes involving liquids, gases, and vapors. By assessing the difference in pressure, operators can identify blockages in pipes, monitor filter conditions, and regulate flow rates.

How Differential Pressure Gauges Work

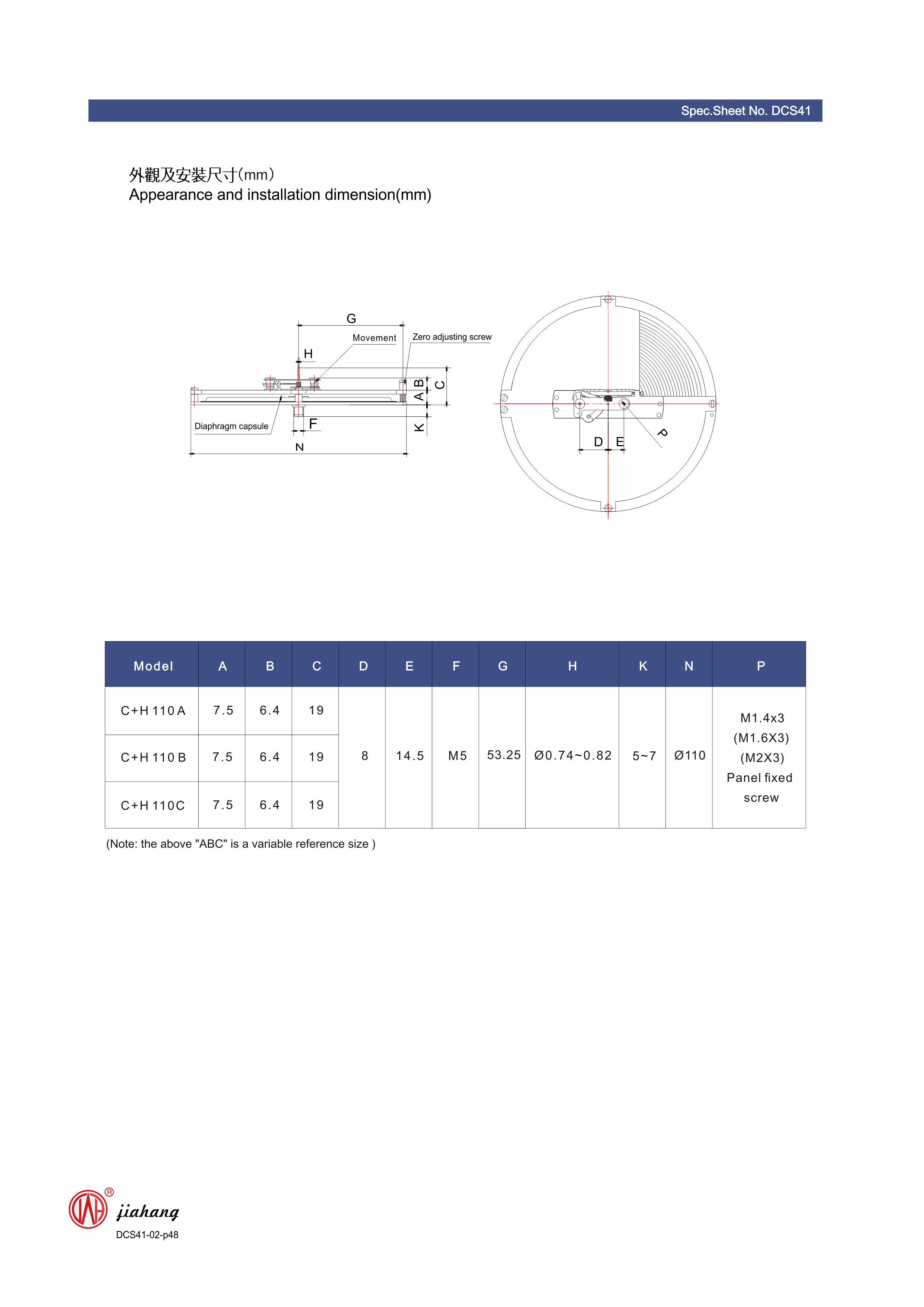

At its core, a differential pressure gauge consists of two pressure ports one connected to the high-pressure side of a system and the other to the low-pressure side. These ports lead to a diaphragm or a sensing element within the gauge. When there’s a difference in pressure, the diaphragm flexes, causing a mechanical movement that translates into a readable value on the display. The design ensures that operators receive real-time data to make informed decisions about the system's health.

Importance of NPT Factories in Manufacturing

National Pipe Taper (NPT) is a standardized thread design used mainly for connecting pipes and fittings in various applications. In the manufacturing of differential pressure gauges, NPT standards ensure a consistent and secure connection between the gauge and the piping system. This uniformity is crucial for preventing leaks, maintaining accurate measurements, and upholding safety mechanisms in high-pressure environments.

Factories specializing in NPT production adhere to strict manufacturing guidelines to ensure compatibility with a range of pipe sizes and materials. This adaptability makes NPT-fitted differential pressure gauges indispensable across many industries, including oil and gas, pharmaceuticals, water treatment, and HVAC systems.

Features of NPT Differential Pressure Gauges

differential pressure gauge 1 2 npt factories

1. Accuracy and Reliability Instruments manufactured with NPT connections are known for their reliability and precision in readings, which are essential for maintaining the integrity of industrial processes.

2. Durable Construction NPT gauges are often made from robust materials resistant to corrosion and high temperatures, ensuring longevity and reduced maintenance costs.

3. Variety of Options These gauges come in various sizes and pressure ranges, making it easier for industries to find a product that fits their unique requirements.

4. Easy Installation The standardized threading of NPT connections simplifies the installation process, allowing for quick integration into existing systems without the need for specialized tools.

Applications of Differential Pressure Gauges

Differential pressure gauges find applications in numerous fields

- HVAC Systems Monitoring air filters and ensuring optimal airflow. - Oil and Gas Measuring pressure drops across filters and separators to enhance operational efficiency. - Pharmaceuticals Ensuring sterile conditions by monitoring pressure differentials in fluid systems. - Water Treatment Tracking the efficiency of membrane filtration systems.

Conclusion

Differential pressure gauges are indispensable tools in modern industrial applications, ensuring systems operate efficiently and safely. Their construction in NPT factories highlights a commitment to quality and standardization, providing operators with accurate and reliable performance. Understanding the functionalities and applications of these gauges allows industries to optimize their processes and enhance overall system performance. As technology advances and industries evolve, the role of differential pressure gauges will undoubtedly remain critical, fostering innovation and maintaining safety across diverse operational landscapes.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025