Ott . 30, 2024 10:45 Back to list

flanged diaphragm seal pressure gauge service

Flanged Diaphragm Seal Pressure Gauge Service

Flanged diaphragm seal pressure gauges are critical components in many industrial applications where accurate pressure measurement is essential. These specialized devices are designed to provide precise readings even under challenging conditions, making them indispensable in industries such as oil and gas, chemical processing, and pharmaceuticals.

The primary function of a flanged diaphragm seal is to isolate the pressure gauge from the process fluid. This is crucial in situations where the fluid is corrosive, viscous, or contains particulates that could damage the gauge. The diaphragm acts as a barrier, allowing the pressure to be transmitted through a liquid-filled cavity, which ensures that only the pressure—rather than the fluid itself—affects the gauge readings. This not only extends the lifespan of the pressure gauge but also maintains the integrity of the measurement.

One of the key features of flanged diaphragm seals is their ability to handle extreme temperatures and pressures. The flanged connection allows for a secure and leak-proof installation, making them reliable in high-stress environments. Additionally, these seals can be customized to meet specific process requirements, including different materials that can withstand various corrosive substances.

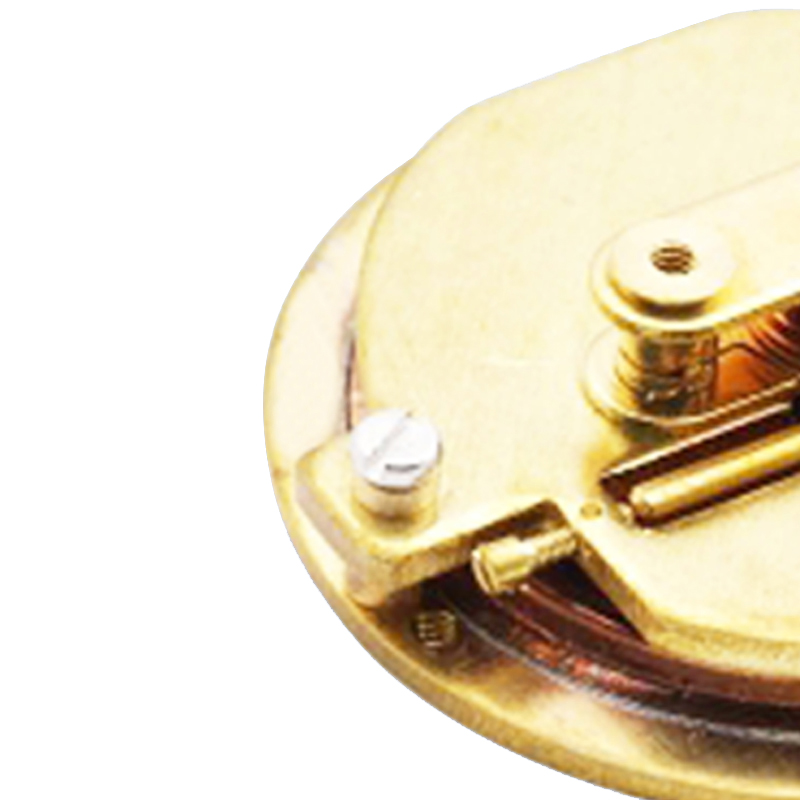

flanged diaphragm seal pressure gauge service

When selecting a flanged diaphragm seal pressure gauge, it is essential to consider several factors, including the type of fluid being measured, temperature ranges, and the desired accuracy. The material of the diaphragm should be compatible with the process fluid to prevent chemical reactions that could compromise the readings or damage the equipment. Common materials include stainless steel, Teflon, and various alloys, each selected based on the specific application needs.

Regular maintenance and calibration of flanged diaphragm seal pressure gauges are crucial for ensuring long-term reliability and accuracy. Routine checks can identify potential issues before they escalate, such as leaks or blockages in the diaphragm seal. Additionally, recalibrating the gauge periodically can help maintain its accuracy, ensuring that the measurements remain consistent over time.

In summary, flanged diaphragm seal pressure gauges are vital for accurate pressure measurement in demanding industrial environments. Their design allows them to withstand harsh conditions while protecting sensitive measurement components, leading to improved reliability and performance. Investing in high-quality flanged diaphragm seals and implementing a regular maintenance schedule is essential for any operation that relies on precise pressure readings.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025