Ago . 12, 2024 16:46 Back to list

High Precision Differential Pressure Gauge for Enhanced Measurement Accuracy and Performance in Various Applications

Understanding Jah High Accuracy Differential Pressure Gauges

In various industrial applications, precise measurement of pressure differentials is crucial for ensuring operational efficiency and safety. The Jah High Accuracy Differential Pressure Gauge stands out as an essential instrument for obtaining reliable and accurate readings in a variety of settings, including HVAC systems, filtration processes, and process control systems.

What is a Differential Pressure Gauge?

A differential pressure gauge measures the difference in pressure between two points within a system. This measurement is critical for monitoring processes such as air and gas flow, liquid levels, and filter conditions. The ability to accurately detect slight variations in pressure can prevent equipment failures, optimize process conditions, and enhance overall operational efficiency.

Features of Jah High Accuracy Differential Pressure Gauges

One of the key advantages of the Jah High Accuracy Differential Pressure Gauge is its precision. These gauges are designed using advanced technology that minimizes errors and enhances the accuracy of measurements. Some essential features include

1. High Sensitivity The gauges are built to detect minute changes in pressure, making them suitable for applications where precision is paramount.

2. Durability Constructed with robust materials, Jah gauges can withstand extreme environmental conditions. They are resistant to corrosion and can function effectively in harsh industrial settings.

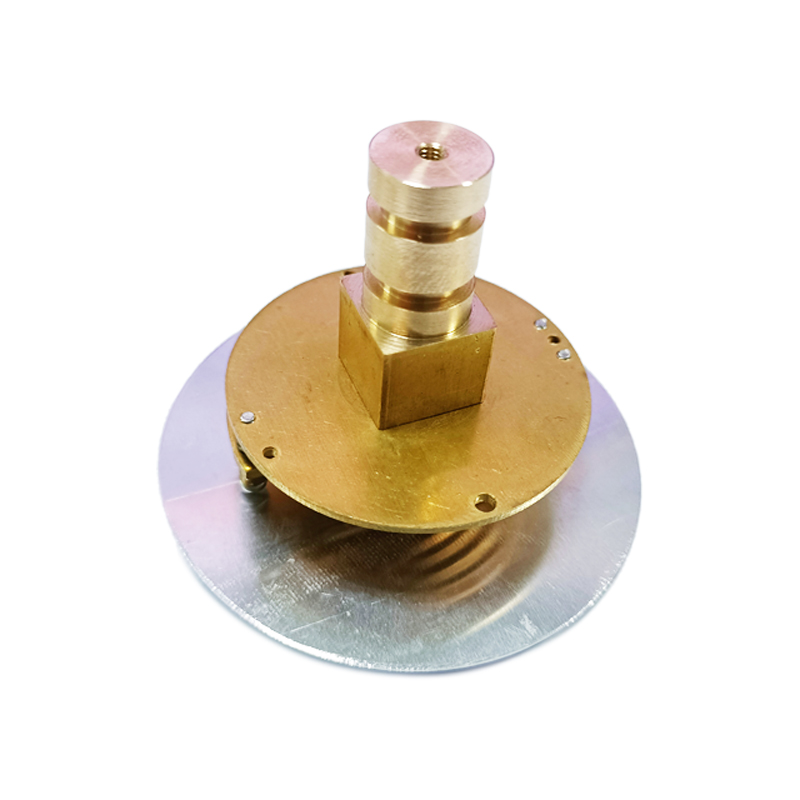

jah high accuracy differential pressure gauge

4. User-Friendly Interface Many models come with digital displays, making it easier for operators to read measurements. This feature enhances usability and reduces the likelihood of human error.

5. Calibration and Maintenance Regular calibration is vital for maintaining accuracy. Jah gauges are designed for easy calibration, allowing operators to ensure consistent performance.

Importance of Accuracy

Accuracy in differential pressure measurement is essential for several reasons. In HVAC systems, for example, accurate readings help maintain optimal airflow, leading to better energy efficiency and indoor air quality. In filtration processes, monitoring differential pressure can signal when a filter needs replacement, thus preventing costly downtime and potential contamination.

Moreover, in processes involving fluid dynamics, accurate differential pressure readings allow for precise control of flow rates, which is critical for maintaining the integrity of chemical reactions and achieving desired product qualities.

Conclusion

In conclusion, the Jah High Accuracy Differential Pressure Gauge represents a sophisticated solution for industries that rely on precise pressure measurement. With its superior accuracy, user-friendly features, and robust construction, it helps organizations optimize their operations, enhance safety, and minimize costs associated with equipment failures and inefficiencies.

As industries continue to evolve and demand higher standards for measurement and control, instruments like the Jah High Accuracy Differential Pressure Gauge will play a pivotal role in driving technological advancements and improving operational excellence. Investing in such high-performance measurement equipment is not just a choice but a necessity for businesses aiming to stay competitive in today's fast-paced environment.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025