Dic . 13, 2024 05:51 Back to list

OEM Wika Diaphragm Seal Pressure Gauge for Accurate Measurement Solutions

Understanding OEM WIKA Pressure Gauge with Diaphragm Seal

Pressure measurement is an essential aspect of various industrial processes, ensuring safety and efficiency in operations. Among the tools used for this purpose, the OEM WIKA pressure gauge with a diaphragm seal stands out due to its precision, reliability, and versatility in harsh environments. In this article, we will explore the features, advantages, applications, and maintenance of this specialized pressure gauge.

What is a Diaphragm Seal?

A diaphragm seal is a pressure measuring device that isolates the pressure sensing element from the process medium. It consists of a flexible membrane, typically made from materials such as stainless steel or special alloys, which separates the measuring fluid from the process fluid. This configuration protects the internal components of the pressure gauge from corrosive, viscous, or high-temperature fluids, ensuring that the measurement remains accurate and that the gauge itself has an extended lifespan.

Features of OEM WIKA Pressure Gauge

WIKA, a renowned manufacturer in the field of pressure and temperature measurement, provides OEM (Original Equipment Manufacturer) client solutions, including customized pressure gauges tailored to specific industrial requirements. The OEM WIKA pressure gauge with diaphragm seal boasts several noteworthy features

1. Material Compatibility These gauges are designed with materials that can withstand corrosive substances, high temperatures, and extreme pressures, making them suitable for a wide range of applications.

2. Temperature Range The gauges can operate effectively over a broad temperature range, ensuring accuracy in varying environmental conditions.

3. Pressure Range OEM WIKA pressure gauges are available for different pressure ranges, providing options suitable for low, medium, and high-pressure applications.

4. Hygienic Design For industries requiring high hygiene standards, such as food and pharmaceuticals, WIKA offers hygienic diaphragm seals that comply with relevant regulations.

5. Customizable Options The versatility of OEM solutions means that clients can have gauges tailored to meet their specific requirements in terms of dimensions, pressure range, and materials.

Advantages of Using OEM WIKA Pressure Gauge with Diaphragm Seal

1. Protection of Internal Components The diaphragm seal protects the gauge's internals from damaging pressures and aggressive fluids, thus enhancing durability.

2. Enhanced Accuracy By isolating the pressure sensor from direct contact with the process medium, the diaphragm seal minimizes the risk of measurement errors due to fluctuations in temperature and pressure.

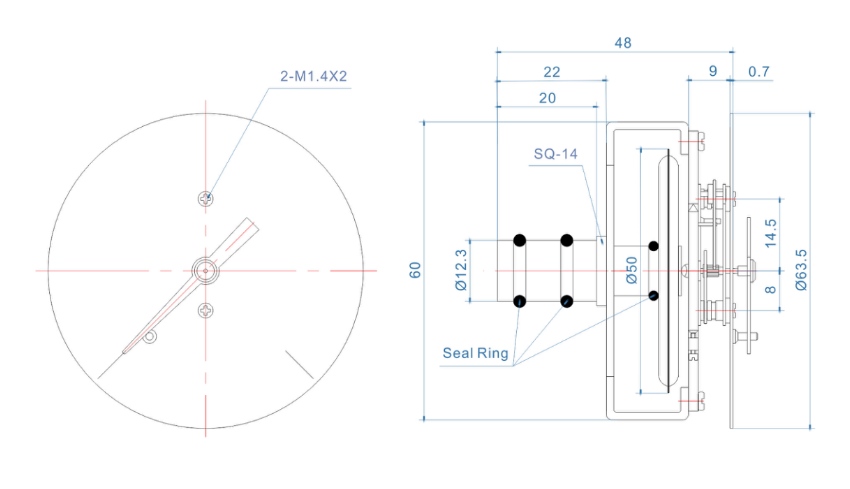

oem wika pressure gauge with diaphragm seal

4. Versatility Across Industries These gauges find applications in various sectors, including chemical processing, oil and gas, pharmaceuticals, food and beverage, and HVAC systems, due to their adaptable design.

Applications of OEM WIKA Pressure Gauge with Diaphragm Seal

Due to their robust construction and ability to handle harsh conditions, OEM WIKA pressure gauges are widely used in numerous applications

- Chemical Processing Monitoring and controlling pressures in chemical reactors, preventing hazardous situations.

- Pharmaceuticals Ensuring the integrity of the manufacturing process by accurately measuring pressures in sterile environments.

- Oil and Gas Providing reliable pressure readings in exploration and production areas where exposure to extreme conditions is common.

- Food and Beverage Measuring pressures in processes involving cleaning, sterilization, and pasteurization without risk of contamination.

Maintenance of OEM WIKA Pressure Gauge

To ensure optimal performance and longevity, regular maintenance of the OEM WIKA pressure gauge with diaphragm seal is necessary. Key maintenance practices include

1. Periodic Calibration Regular calibration against known standards to ensure accuracy.

2. Visual Inspections Checking for any visible signs of wear, corrosion, or damage to the gauge and diaphragm seal.

3. Cleaning Keeping the pressure gauge clean, especially in hygienic applications, to prevent contamination that could affect measurements.

4. Proper Installation Ensuring that the gauge is installed according to the manufacturer's recommendations to avoid unnecessary stress and potential failure.

Conclusion

The OEM WIKA pressure gauge with diaphragm seal is an indispensable instrument in various industries. Its combination of precision, durability, and protection from harsh environments makes it an ideal choice for ensuring safety and efficiency in pressure measurement tasks. By understanding its features and maintaining it properly, industries can significantly enhance their operational reliability and effectiveness.

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025

-

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

NewsMay.23,2025

-

Industrial Differential Pressure Gauges Global Supplier & Pricelist

NewsMay.23,2025

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025