Set . 28, 2024 16:53 Back to list

High-Quality Pressure Gauges from Leading Precision Instruments Manufacturer

The Role of Precision Instruments in Pressure Gauges A Deep Dive

In today's ever-evolving industrial landscape, precision and reliability are paramount. Among the myriad of tools that ensure operational excellence, pressure gauges stand out as essential instruments, providing vital readings that influence safety, efficiency, and performance across various sectors. At the heart of this technology are companies specializing in precision instruments, dedicated to manufacturing pressure gauges that meet stringent industry standards.

Pressure gauges are devices used to measure the pressure of gases or liquids, and they find applications in various fields, including manufacturing, automotive, HVAC systems, and even medical equipment. The accuracy of these devices is critical. An incorrect pressure reading can lead to catastrophic failures, reduced efficiency, or even accidents. This is where precision instruments come into play, offering advanced technology and meticulous craftsmanship to ensure that pressure readings are both accurate and reliable.

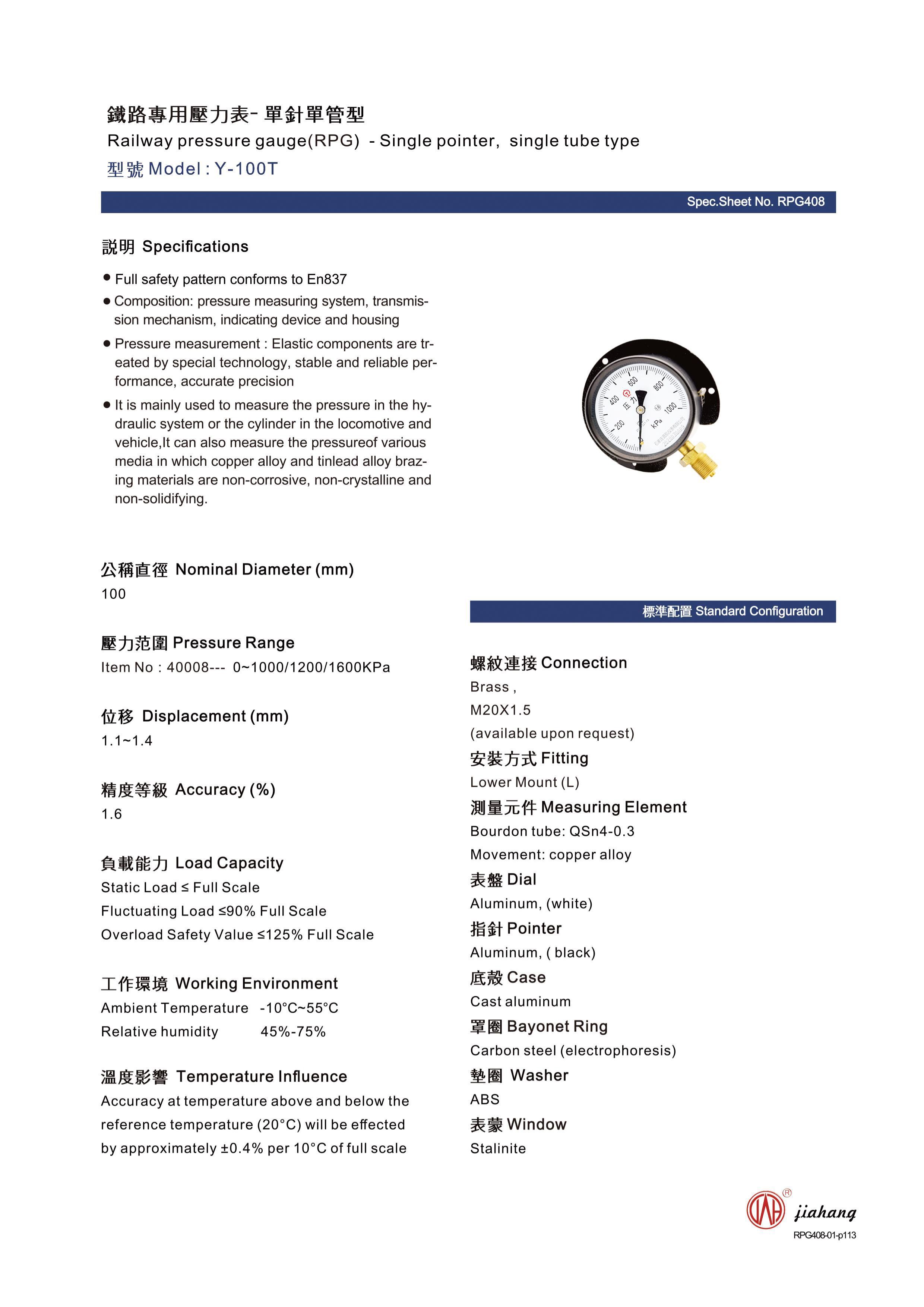

One of the key features that set high-quality pressure gauges apart is their construction and materials. Precision instrument manufacturers typically use high-grade materials such as stainless steel and brass, which not only enhance durability but also improve resistance to corrosion and extreme environmental conditions. This durability is crucial, especially in industries like oil and gas, where gauges are subjected to harsh operational environments.

Moreover, the heart of a pressure gauge—the sensing element—plays a pivotal role in its performance. Different types of sensing elements, such as bourdon tubes, diaphragm sensors, or piezoresistive sensors, are employed based on the specific application and required accuracy level. For instance, bourdon tube gauges are widely used for measuring high pressures, while diaphragm gauges are preferred for low-pressure applications or corrosive substances due to their ability to prevent contact between the process media and the mechanical parts of the gauge.

precision instruments pressure gauges company

Another critical aspect of precision in pressure gauges is calibration. Companies specializing in precision instruments often have in-house calibration labs equipped with advanced technology to ensure that their gauges deliver accurate measurements. Since pressure can be affected by environmental variables such as temperature and humidity, regular recalibration is necessary to maintain the accuracy of these devices. A reliable precision instrument manufacturer will provide detailed calibration certificates, guaranteeing the performance and accuracy of each gauge sold.

In an era where data-driven decisions are pivotal, integration of digital technology in pressure measurement has become increasingly significant. Many modern pressure gauges now come equipped with digital displays and smart features that allow for real-time monitoring and data logging. This advancement not only improves accuracy but also facilitates integration into automated systems, providing operators with instant feedback and the ability to make informed decisions.

Precision instruments in pressure gauges are not just limited to industrial applications; they also find their way into research laboratories and other specialized fields where precise measurements are crucial. In these settings, high-performance pressure gauges enable scientists and researchers to conduct experiments and tests with a level of accuracy that was previously difficult to achieve.

In conclusion, the significance of precision instruments in the realm of pressure gauges cannot be overstated. As industries continue to push for higher efficiency and safety standards, the demand for accurate and reliable pressure measurement will only grow. Companies that specialize in manufacturing precision instruments will play an indispensable role in meeting these needs, contributing not only to the reliability of various applications but also to the overall advancement of technology across sectors. As we move forward, the integration of digital features alongside traditional mechanical gauges will shape the future of pressure measurement, driving innovation and ensuring that industries are equipped with the best tools available.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025