Ago . 14, 2024 05:28 Back to list

Understanding the Design and Functionality of Differential Pressure Gauges in Chinese Industries

Understanding the Construction of Pressure Differential Gauges in China

Differential pressure gauges are essential instruments widely used in various industries to measure the pressure difference between two points in a system. These devices are crucial in process control, fluid dynamics, and other applications where maintaining specific pressure levels is paramount. In China, the construction of these gauges involves a combination of advanced technology, high-quality materials, and stringent manufacturing standards.

Components of Differential Pressure Gauges

A differential pressure gauge typically consists of several key components. At its core are two pressure sensing elements, which detect the pressure from the two different points. These sensing elements are often filled with a fluid or gas that transmits the pressure changes to a readout mechanism. The most common types of sensing elements include diaphragm cells and Bourdon tubes, each offering unique advantages in responsiveness and accuracy.

In addition to the sensing elements, differential pressure gauges include a housing, usually made from stainless steel or other durable materials to withstand harsh environments. The casing not only protects the internal components but also ensures the gauge remains operable in high-pressure or corrosive conditions. Furthermore, many gauges are equipped with a calibrated scale or digital display, allowing for easy reading of the pressure differential.

Manufacturing Process

The construction of differential pressure gauges in China adheres to rigorous manufacturing protocols. The process begins with the selection of high-grade materials. For instance, stainless steel is preferred for housing due to its strength and corrosion resistance, which enhances the durability of the gauges.

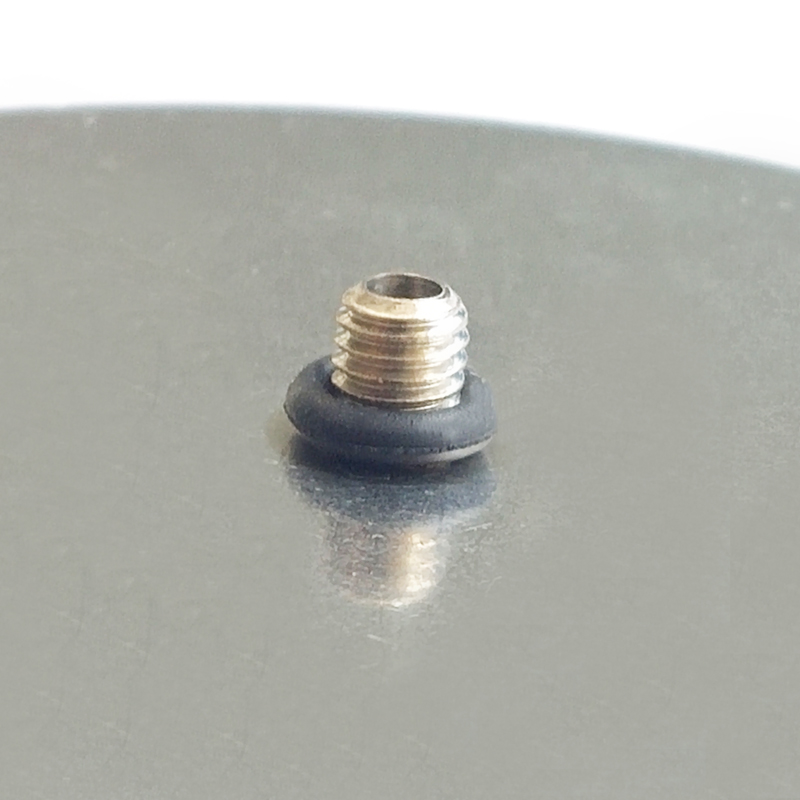

china differential pressure gauge construction

Once materials are secured, the manufacturing process involves precision engineering techniques. The production of sensing elements, such as Bourdon tubes, requires exact calibration to ensure accuracy. Skilled technicians utilize computer numerical control (CNC) machines for high precision in the machining process, creating components that fit together seamlessly.

After assembling the components, quality control tests are vital. Differential pressure gauges undergo various tests to assess their accuracy, responsiveness, and overall performance under different conditions. These tests may include pressure cycling, calibrations against standards, and environmental tests to simulate actual working conditions.

Applications and Importance

In China, differential pressure gauges are used across multiple sectors including oil and gas, water treatment, HVAC systems, and pharmaceuticals. For instance, in the oil and gas industry, these gauges help monitor the pressure across pipelines to ensure the safe transport of crude oil and natural gas. In HVAC applications, they play a crucial role in ensuring that the air pressure within ducts is maintained at desired levels, promoting energy efficiency and comfort.

Another important application is in filtration systems, where differential pressure gauges monitor filter conditions. A significant change in differential pressure can indicate a blocked filter, prompting timely maintenance and preventing operational disruptions. The ability of these gauges to ensure process efficiency and safety highlights their critical role in industrial applications.

Conclusion

The construction of differential pressure gauges in China exemplifies a blend of traditional craftsmanship and modern technology. By utilizing advanced manufacturing processes and adhering to strict quality standards, these instruments provide reliable and accurate measurements essential for various industrial applications. As industries continue to evolve, the demand for high-quality differential pressure gauges will remain strong, fostering innovations in design and technology that will ultimately improve operational efficiencies across the board.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025