Nov . 22, 2024 15:01 Back to list

wika 4 differential pressure gauge factories

Understanding the Importance of Differential Pressure Gauges in Industrial Applications

Differential pressure gauges are crucial instruments in various industrial applications, providing critical measurements that ensure the safe and efficient operation of systems. Understanding their function and the role they play in different sectors—such as oil and gas, chemicals, and water treatment—can significantly enhance operational efficiency and safety.

What is a Differential Pressure Gauge?

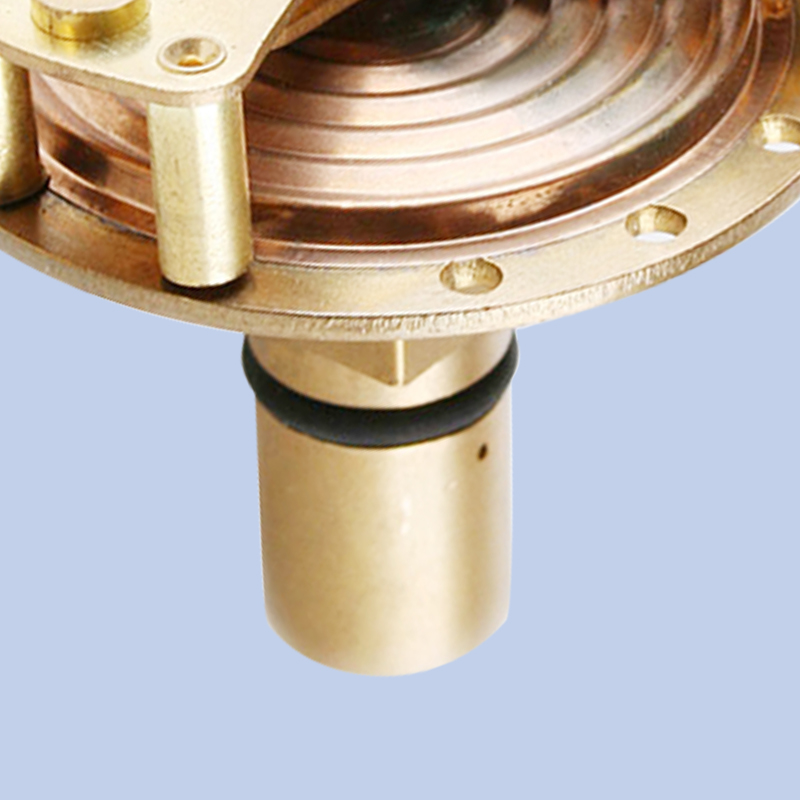

A differential pressure gauge measures the difference in pressure between two points in a system. This capability makes them invaluable in numerous applications. Typically, these gauges feature two pressure ports one connected to a high-pressure side and the other to a low-pressure side. The device then displays the pressure difference, allowing users to monitor and control processes effectively.

Applications Across Industries

1. Oil and Gas Sector In the oil and gas industry, maintaining the right pressure differential is essential for safety and efficiency. Differential pressure gauges are used to monitor pressure drops across filters and separators. If pressure drops below a certain threshold, it can indicate blockages or other issues that could lead to operational failures.

2. Chemical Processing The chemical industry often operates under varying pressure conditions. Differential pressure gauges help monitor reactors, distillation columns, and pipelines. By understanding these pressure differentials, operators can ensure optimal flow rates, prevent overpressures, and maintain product quality.

3. Water Treatment Facilities In water treatment applications, differential pressure gauges are utilized to monitor the performance of filtration systems and maintain efficient operation. They provide essential data for detecting fouling and blockages in filters, allowing for timely maintenance and ensuring clean water supply.

Key Benefits of Differential Pressure Gauges

- Operational Efficiency By providing real-time data on pressure differentials, these gauges help optimize processes and reduce downtime. This capability leads to significant savings in operational costs and enhances overall system performance.

wika 4 differential pressure gauge factories

- Safety Monitoring differential pressures is vital for preventing overpressurization, which can lead to catastrophic failures and safety hazards. In industries where pressure control is paramount, differential pressure gauges act as a first line of defense against potential accidents.

- Predictive Maintenance Differential pressure readings can be used to forecast maintenance needs. A sudden change in pressure differential may indicate wear, blockages, or other issues requiring attention. By facilitating predictive maintenance, these gauges can minimize unscheduled outages and extend the lifespan of equipment.

Choosing the Right Differential Pressure Gauge

When selecting a differential pressure gauge, several factors must be considered

1. Measurement Range The gauge must be capable of measuring the required range of pressure differentials specific to the application.

2. Fluid Compatibility Different materials are used in the construction of gauges, affecting compatibility with various fluids. It is crucial to select a gauge that withstands the chemical and physical properties of the fluid being measured.

3. Installation Conditions The environment where the gauge will be installed—such as temperature extremes, humidity, and potential for physical impact—will influence the choice of gauge.

4. Accuracy and Calibration The accuracy of the gauge is vital for reliable measurements. Regular calibration is also necessary to maintain accuracy over time, ensuring that the gauge provides valid data for decision-making.

Conclusion

Differential pressure gauges are indispensable tools across numerous industries. Their ability to monitor pressure differences and provide real-time insights plays a vital role in enhancing operational efficiency, safety, and predictive maintenance. By understanding the importance of these gauges and selecting the right equipment, industries can ensure smoother operations and mitigate risks effectively. As technology advances, the evolution of differential pressure measurement will continue to support innovations across various sectors, demonstrating their integral role in modern industrial processes.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025