Ott . 11, 2024 00:16 Back to list

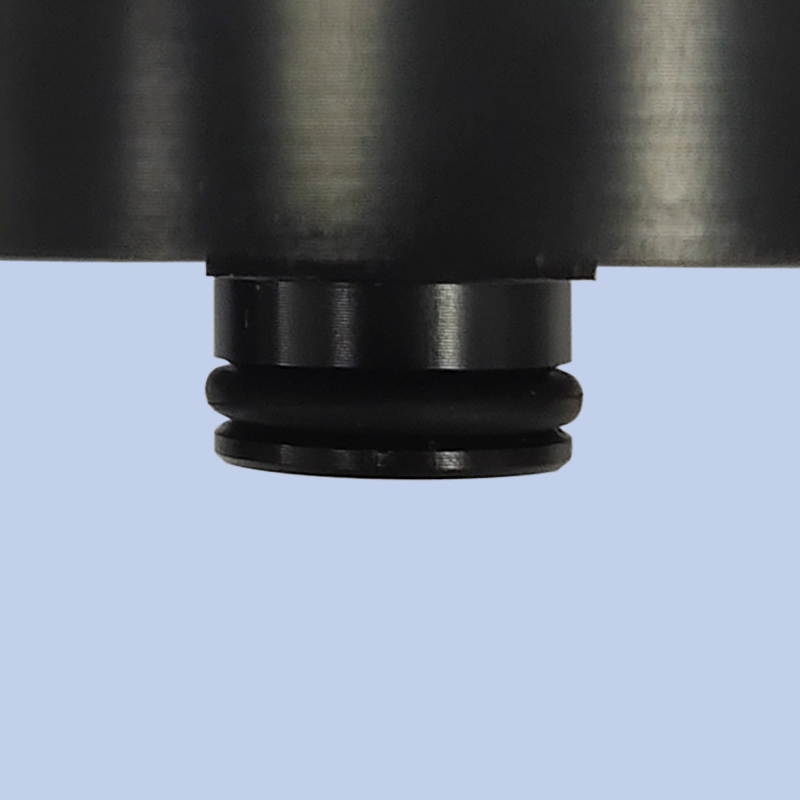

wika diaphragm seal type pressure gauge jah

Understanding the WIKA Diaphragm Seal Type Pressure Gauge

Pressure measurements are vital in numerous industrial applications, and the accuracy of these measurements is paramount for maintaining process efficiency, safety, and reliability. Among the various types of pressure measurement devices available, the WIKA diaphragm seal type pressure gauge stands out due to its distinctive features and advantages, particularly in challenging environments.

What is a Diaphragm Seal?

A diaphragm seal is a mechanical device designed to isolate the pressure sensing element from the process medium, ensuring that the pressure gauge can operate without being directly influenced by the medium's properties. This is especially beneficial in cases where the medium may be corrosive, viscous, or contain particulates that could damage standard pressure gauges. The diaphragm is made of materials such as stainless steel, PTFE, or Hastelloy, chosen based on compatibility with the process fluid.

Advantages of the WIKA Diaphragm Seal Pressure Gauge

1. Protection from Corrosion and Contamination One of the primary advantages of using a diaphragm seal is its ability to protect the pressure sensing element from corrosive and aggressive fluids. The diaphragm acts as a barrier, preventing direct contact with the fluid and extending the life of the gauge.

2. Improved Accuracy and Reliability By isolating the pressure measurement from the process medium, the diaphragm seal helps maintain accuracy even in fluctuating environmental conditions. This ensures that readings are reliable and consistent, which is crucial for applications in industries like pharmaceuticals, food and beverage, and chemical processing.

3. Adaptability to Various Conditions The WIKA diaphragm seal pressure gauge can be used in a wide range of applications and environments, including high temperatures and pressures. Its versatility makes it suitable for diverse industries, from oil and gas to water treatment.

4. Reduced Maintenance Needs Since the diaphragm seal prevents direct contact with the process medium, the wear and tear on the pressure gauge is significantly reduced. This results in lower maintenance requirements and less frequent replacement, contributing to overall cost savings for organizations.

wika diaphragm seal type pressure gauge jah

5. Customization Options WIKA offers a variety of diaphragm seal configurations tailored to specific industrial needs. Customers can select from different materials, sizes, and connection types, ensuring that the gauge fits perfectly into their system requirements and meets the specific characteristics of their unique applications.

Applications of WIKA Diaphragm Seal Pressure Gauges

The versatility of the WIKA diaphragm seal type pressure gauge allows it to be utilized across various sectors

- Chemical and Petrochemical Industries These industries often deal with hazardous and corrosive materials. A diaphragm seal protects the gauge while providing accurate pressure readings crucial for process control and safety.

- Food and Beverage Industry Ensuring the integrity of food products is paramount. Diaphragm seals help maintain the hygiene and cleanliness of the system while preventing contamination from the process fluid.

- Pharmaceutical Manufacturing In this sector, strict regulatory standards must be met. Accurate and reliable pressure measurements are essential to ensure product quality and safety.

- Water Treatment Plants Monitoring pressure in water treatment systems is critical for efficient operation. Diaphragm seals help protect gauges in these environments, where the presence of particulates could lead to inaccurate readings.

Conclusion

The WIKA diaphragm seal type pressure gauge is a robust and reliable solution for pressure measurement in diverse industrial applications. Its design not only ensures the longevity and accuracy of pressure readings but also facilitates compliance with safety and quality standards across various sectors. By choosing diaphragm seal technology, companies can enhance their process reliability, reduce maintenance costs, and ultimately achieve a more efficient operational workflow. As industries continue to evolve and face new challenges, the WIKA diaphragm seal pressure gauge stands as a testament to innovation in pressure measurement technology.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025