12月 . 03, 2024 16:26 Back to list

Custom Inline Differential Pressure Gauge Solutions for Accurate Process Measurement

Custom Differential Pressure Gauge in Line An In-Depth Look

In various industrial applications, monitoring fluid or gas flow is crucial for operational efficiency, safety, and regulatory compliance. One of the critical instruments used for this purpose is the differential pressure gauge. Custom differential pressure gauges in line offer specific solutions tailored to meet the unique needs of various industries, ensuring accurate measurements while enhancing productivity and safety.

What is a Differential Pressure Gauge?

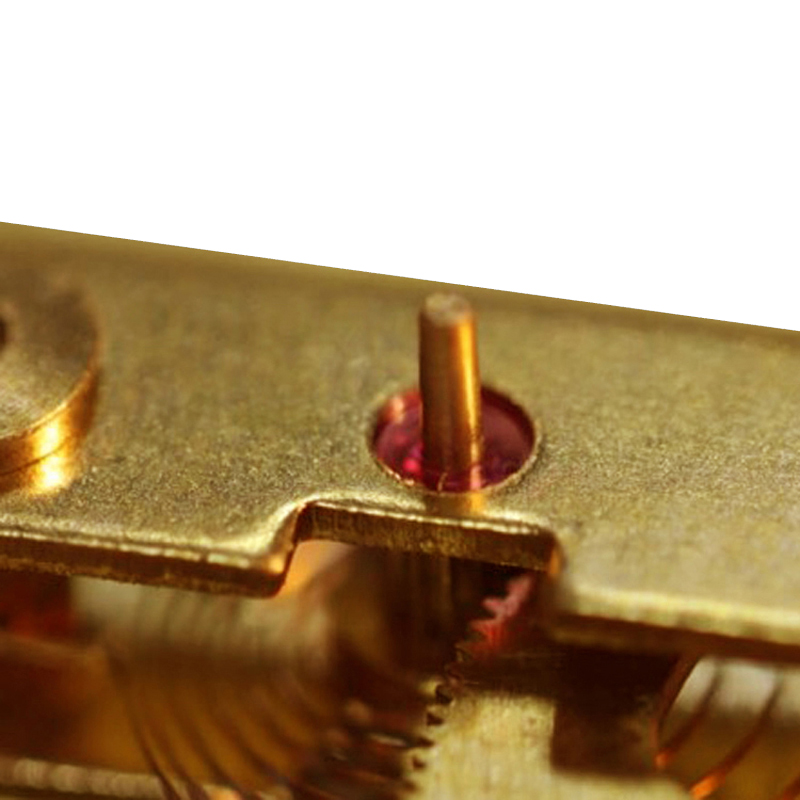

A differential pressure gauge is an instrument that measures the difference in pressure between two points in a system. This measurement is vital for assessing flow rates, detecting blockages, and ensuring that processes operate within safe parameters. The design of a differential pressure gauge typically includes two inputs one to measure the pressure of the fluid entering the system and another to assess the pressure downstream, thus allowing for the calculation of the pressure differential.

Importance of Customization

While standard differential pressure gauges are widely used, customizing these instruments can yield significant benefits. Custom gauges are designed with specific parameters in mind, allowing them to cater to particular applications, environments, or industry standards. Such customization might involve considerations for pressure ranges, material compatibility, size constraints, and specific calibration requirements.

For instance, a chemical processing plant dealing with corrosive fluids may require a differential pressure gauge built from specialized materials like Hastelloy or Teflon. These materials can withstand hostile environments, ensuring longevity and reliable readings. Similarly, a food processing facility might need gauges that meet stringent hygiene standards, which would involve custom designs that minimize dead spaces and facilitate easy cleaning.

Applications of Custom Differential Pressure Gauges

Custom differential pressure gauges are versatile instruments found in numerous industries, including

1. Oil and Gas They monitor pressure differentials in pipelines and tanks, helping to prevent leaks and ensuring system integrity. 2. Water Treatment Gauges are used to measure the pressure drop across filters, assisting in timely maintenance to ensure optimal performance.

custom differential pressure gauge in line

3. HVAC Systems In heating, ventilation, and air conditioning systems, these gauges monitor air pressure across filters and ductwork, enabling efficient airflow management.

4. Pharmaceuticals Custom gauges comply with regulatory requirements and quality control by monitoring critical pressure differentials in manufacturing processes.

5. Power Generation In this sector, they measure pressure differentials in steam and gas systems, providing critical information for performance optimization.

Benefits of In-Line Installation

When differential pressure gauges are installed in-line, they allow for continuous monitoring without disrupting the flow of the system. This installation method offers real-time data, leading to immediate response capabilities in operational anomalies. Continuous monitoring assists operators in identifying trends and anomalies, enabling predictive maintenance practices. Furthermore, by integrating these gauges into the control system, operators can automate responses to pressure fluctuations, enhancing safety and efficiency.

Selecting the Right Custom Differential Pressure Gauge

Choosing the right custom differential pressure gauge requires careful consideration of various factors

- Operating Environment Understand the temperature and pressure conditions, as well as the media being measured. - Size and Space Constraints Custom solutions can be designed to fit within specific spatial limitations. - Calibration and Accuracy Requirements Depending on the application, specific thresholds for accuracy may need to be met. - Compliance Standards Different industries may have varying regulatory requirements, driving the need for tailored solutions.

Conclusion

In conclusion, custom differential pressure gauges in line are indispensable tools across various industries. They offer precise measurements that contribute to safety, efficiency, and adherence to industry standards. By investing in custom solutions, companies can ensure that their operational needs are met while also gaining a competitive edge. With technology improving and the increasing complexity of industrial systems, the demand for tailored solutions is likely to rise, making the role of custom differential pressure gauges increasingly important in the years to come.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025