9月 . 30, 2024 06:35 Back to list

Custom Flanged Diaphragm Pressure Gauge for Accurate Pressure Measurement Solutions

Custom Flanged Diaphragm Pressure Gauge Enhancing Precision and Performance

In industrial settings, the measurement of pressure is critical for ensuring operational efficiency, safety, and compliance with regulations. One of the most reliable tools for this purpose is the diaphragm pressure gauge, particularly the custom flanged diaphragm pressure gauge. This specialized instrumentation is designed to provide highly accurate pressure readings in a variety of applications, from manufacturing to oil and gas drilling.

Understanding Diaphragm Pressure Gauges

A diaphragm pressure gauge measures the pressure of gases and liquids by monitoring the deflection of a flexible diaphragm. As pressure is applied, the diaphragm bends, causing a connected mechanism to indicate the pressure level on a calibrated scale. The diaphragm's design allows it to respond quickly to changes in pressure, making it ideal for dynamic systems where pressure fluctuations are common.

Advantages of Flanged Connections

Flanged connections in pressure gauges provide numerous benefits. Flanges allow for a secure and leak-proof connection to pipes and other equipment, facilitating quick installation and maintenance. They are especially advantageous in high-pressure applications where the reliability of joints is crucial. Custom flanged diaphragm pressure gauges are tailored to meet specific industry standards and requirements, ensuring compatibility with various piping systems.

Customized Solutions for Diverse Applications

One of the primary benefits of using a custom flanged diaphragm pressure gauge is the ability to tailor the product to specific needs. Industries such as chemical processing, pharmaceuticals, and food and beverage require pressure gauges that can withstand harsh environments and fluctuating conditions. Custom gauges can be designed with specialized materials, ranges, and features to meet these stringent requirements.

For example, gauges can be equipped with corrosion-resistant materials for chemical applications or hygienic designs for food processing. Additionally, customization might include different pressure ranges, allowing operators to select a gauge that aligns perfectly with their operational needs. This flexibility ensures higher accuracy and minimizes the risk of instrument failure.

Precision Engineering for Accurate Measurements

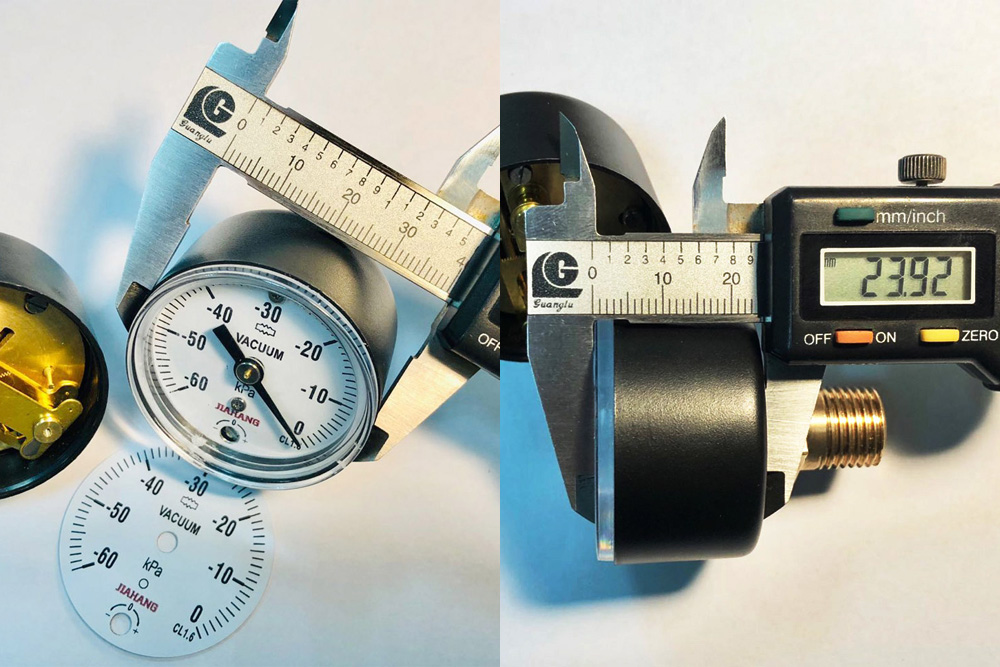

custom flanged diaphragm pressure gauge

The performance of a pressure gauge directly influences the efficiency and safety of industrial processes. Custom flanged diaphragm pressure gauges are engineered with precision to provide reliable and accurate measurements. They undergo rigorous testing and quality assurance processes to maintain high standards.

The accuracy of these gauges can be crucial in preventing overpressure situations, which can lead to catastrophic failures and safety hazards. By providing real-time data, custom gauges allow operators to make informed decisions and maintain optimal operating conditions.

Ensuring Safety and Compliance

In many industries, compliance with safety regulations and standards is non-negotiable. Custom flanged diaphragm pressure gauges can be designed to comply with specific industry codes, such as ASME (American Society of Mechanical Engineers) or API (American Petroleum Institute) standards, ensuring that they are suitable for a range of applications.

Moreover, these gauges can integrate safety features, such as pressure relief systems or alarms, that alert operators to abnormal pressure conditions. Such features are instrumental in safeguarding equipment and personnel.

The Importance of Regular Maintenance

Even the most advanced custom flanged diaphragm pressure gauges require regular maintenance to ensure sustained performance. Routine calibration, inspection for wear and tear, and cleaning of the diaphragm are essential to maintain accuracy and reliability. Manufacturers often provide guidelines and support for maintenance routines to maximize the lifespan and performance of the gauges.

Conclusion

In conclusion, custom flanged diaphragm pressure gauges represent a vital component in the toolbox of industries reliant on precise pressure measurements. Their combination of accurate readings, robust design, and customizable features make them indispensable in environments where operational conditions can be challenging. By ensuring adherence to safety standards and facilitating continuous monitoring, these gauges play a critical role in enhancing overall system performance. Investing in high-quality, custom solutions not only guarantees better measurement accuracy but also promotes a safer and more efficient working environment.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025