8月 . 10, 2024 12:30 Back to list

Factories Specializing in Manufacturing Diaphragm-Sealed Pressure Gauges for Various Applications and Industries

The Role of Diaphragm-Sealed Pressure Gauges in Industrial Applications

In various industries, the need for accurate and reliable pressure measurement is paramount. One of the most effective instruments for this job is the diaphragm-sealed pressure gauge. These specialized devices are designed to handle extreme conditions, making them ideal for a wide array of applications, including those involving corrosive fluids and gases, viscous materials, and high-purity processes.

What is a Diaphragm-Sealed Pressure Gauge?

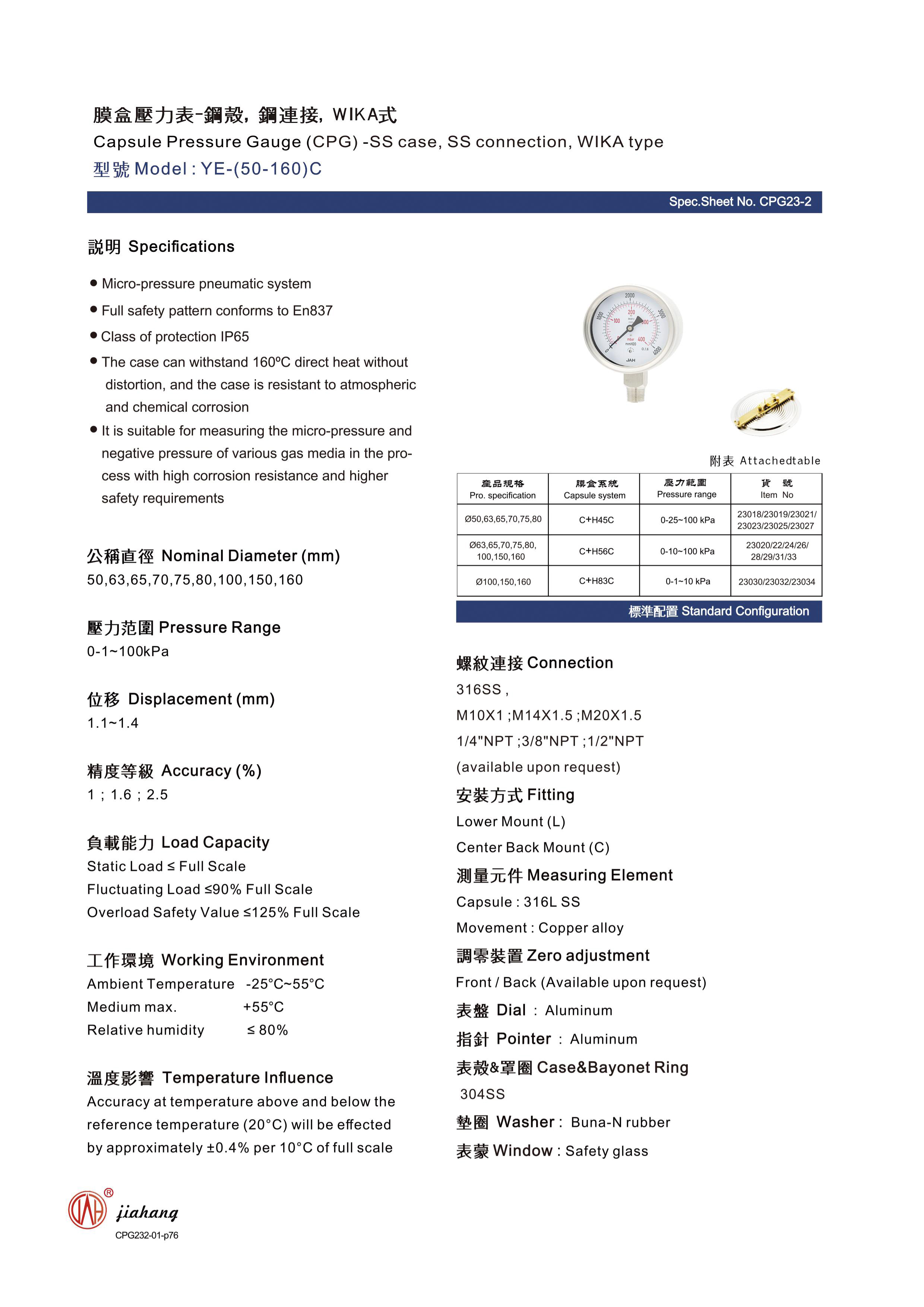

A diaphragm-sealed pressure gauge consists of a pressure gauge that is separated from the process medium by a flexible diaphragm. This diaphragm is usually made from materials resistant to corrosion, such as stainless steel, Hastelloy, or Monel, ensuring the gauge's functionality even when exposed to highly corrosive substances. When pressure from the process medium acts on the diaphragm, it flexes, converting this pressure into a mechanical displacement that can be measured by the gauge's internal mechanism.

Advantages of Diaphragm-Sealed Pressure Gauges

1. Protection Against Contamination Diaphragm seals provide a barrier between the process fluid and the measuring element. This is particularly important in industries like pharmaceuticals and food and beverage, where contamination is a significant concern. The use of diaphragm seals helps maintain the integrity of the process while ensuring accurate pressure readings.

2. Versatility These gauges can be used in a variety of environments, from high-pressure systems to vacuum applications. They can also measure pressure in both gas and liquid mediums, making them incredibly versatile tools for engineers and operators.

3. Long-term Reliability The construction of diaphragm-sealed pressure gauges is robust, allowing them to withstand harsh conditions, including temperature extremes and high levels of pressure. This durability translates to longer service life and lower maintenance costs.

4. Ease of Installation Many diaphragm-sealed gauges are designed for easy installation, often featuring flanged connections. This allows for straightforward integration into existing systems, reducing downtime during installation.

diaphragm sealed pressure gauge factories

Applications in Industry

Diaphragm-sealed pressure gauges are used across numerous sectors, including

- Chemical Manufacturing These gauges are crucial in monitoring chemical processes where the materials used can be aggressive or corrosive. The diaphragm seal prevents chemical exposure to the gauge mechanism, enhancing its longevity.

- Oil and Gas Sector In oil and gas applications, where pressures can vary significantly, diaphragm-sealed gauges provide precise measurements essential for safe operations and regulatory compliance.

- Pharmaceuticals The high standards for cleanliness in pharmaceutical production make diaphragm-sealed gauges indispensable. They ensure that the measurement system does not introduce contaminants, which could affect product quality.

- Food and Beverage Processing In this industry, maintaining hygiene and avoiding cross-contamination is critical. Diaphragm-sealed gauges help monitor processes without compromising cleanliness.

Conclusion

In conclusion, diaphragm-sealed pressure gauges are an essential tool in a broad range of industries. Their unique design, which separates the measuring element from the process media, provides numerous advantages, including protection against contamination, durability, and versatility. As industries continue to seek innovative solutions for maintaining process integrity and operational efficiency, diaphragm-sealed pressure gauges will remain a critical component in achieving these goals. Whether in chemical plants, oil rigs, or food production facilities, these gauges ensure accurate pressure measurement, ultimately contributing to safer and more effective industrial operations.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025