6月 . 21, 2024 13:29 Back to list

Low-pressure diaphragm gauge for monitoring air pressure.

Understanding Low Pressure Diaphragm Pressure Gauges Precision Meets Sensitivity

Low pressure diaphragm pressure gauges have carved a niche in the world of industrial instrumentation due to their exceptional precision and sensitivity in measuring minute pressure variations. These specialized devices are designed to accurately monitor and indicate low-pressure ranges, typically below 600 psi, making them indispensable tools in various sectors such as chemical processing, pharmaceuticals, and HVAC systems.

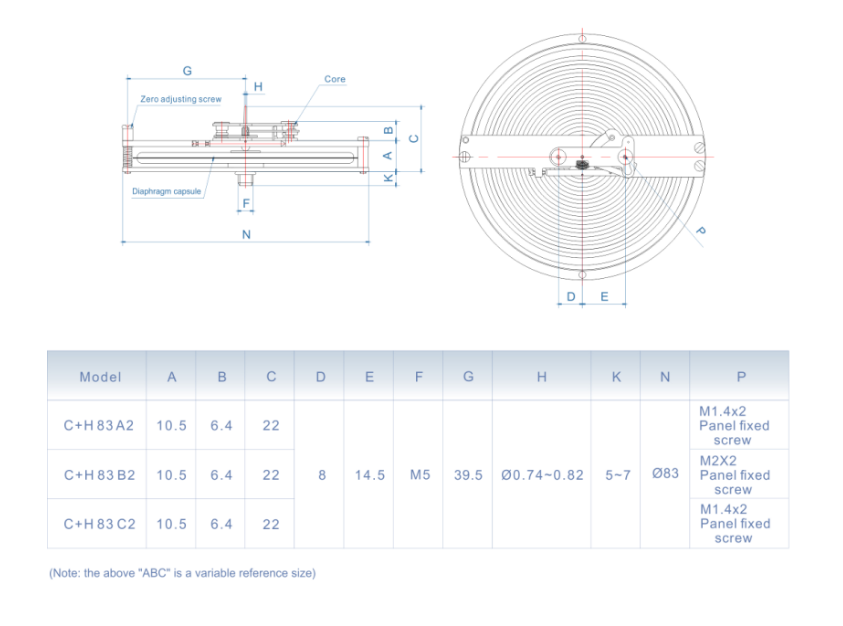

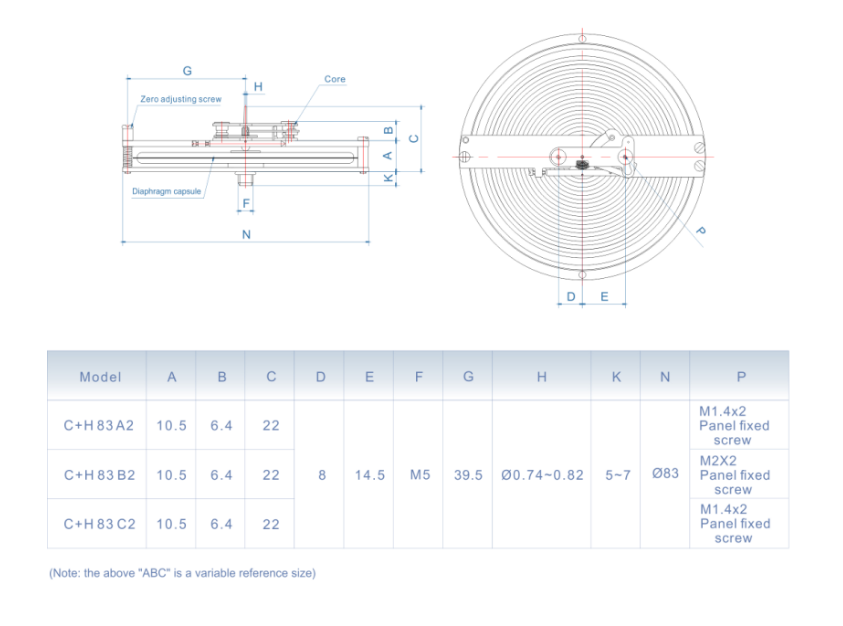

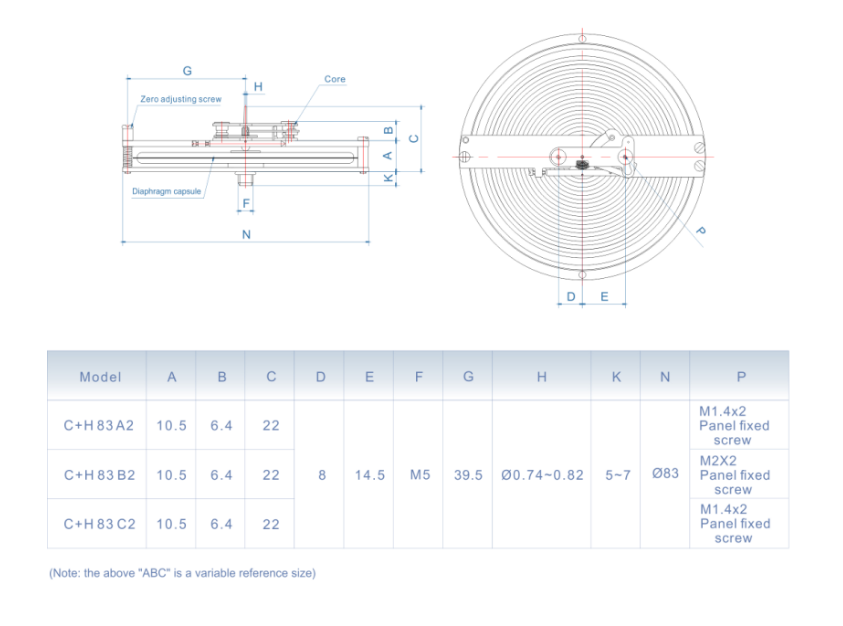

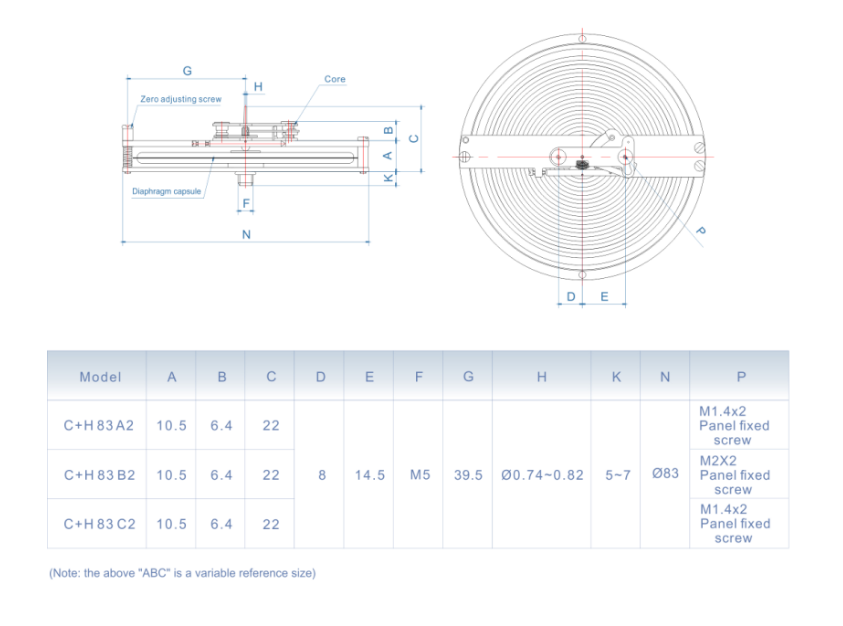

A diaphragm pressure gauge operates on the principle of deflection. It consists of a flexible diaphragm, which acts as a barrier between the process fluid and the internal mechanism of the gauge. When pressure is applied to the diaphragm, it deforms proportionally to the applied force. This deformation is then translated into a measurable mechanical movement, indicating the pressure reading on the dial.

The advantage of a low pressure diaphragm gauge lies in its sensitivity. The thin, flexible diaphragm is highly responsive to even the slightest changes in pressure, ensuring accurate readings in applications where minute pressure fluctuations can significantly impact process efficiency or safety. For instance, in the pharmaceutical industry, precise control of pressure during manufacturing processes is crucial to maintain product quality and consistency.

Moreover, these gauges offer enhanced protection against contamination. The diaphragm acts as a, preventing process fluids from coming into contact with the gauge's internal components, thus prolonging the instrument's lifespan and ensuring reliability in corrosive or hazardous environments The diaphragm acts as a, preventing process fluids from coming into contact with the gauge's internal components, thus prolonging the instrument's lifespan and ensuring reliability in corrosive or hazardous environments The diaphragm acts as a, preventing process fluids from coming into contact with the gauge's internal components, thus prolonging the instrument's lifespan and ensuring reliability in corrosive or hazardous environments The diaphragm acts as a, preventing process fluids from coming into contact with the gauge's internal components, thus prolonging the instrument's lifespan and ensuring reliability in corrosive or hazardous environments

The diaphragm acts as a, preventing process fluids from coming into contact with the gauge's internal components, thus prolonging the instrument's lifespan and ensuring reliability in corrosive or hazardous environments The diaphragm acts as a, preventing process fluids from coming into contact with the gauge's internal components, thus prolonging the instrument's lifespan and ensuring reliability in corrosive or hazardous environments low pressure diaphragm pressure gauges.

Low pressure diaphragm pressure gauges also come in different materials, such as stainless steel, brass, or Monel, to suit varying application requirements. The choice of material is critical, as it influences the gauge's resistance to corrosion, temperature tolerance, and overall durability.

In addition to standard designs, custom-engineered diaphragm pressure gauges are available for specific applications. These tailored solutions can incorporate features like remote seals, digital displays, or special connections to meet unique process demands.

Despite their complexity, low pressure diaphragm gauges require minimal maintenance, adding to their cost-effectiveness. Regular calibration and inspection are necessary to ensure continued accuracy and prevent potential failures.

In conclusion, low pressure diaphragm pressure gauges are vital instruments in industries that rely on precise pressure measurement. Their sensitivity, contamination resistance, and adaptability make them an ideal choice for monitoring delicate processes where small pressure changes can have significant consequences. As technology advances, we can expect further improvements in their design and functionality, enhancing their role in ensuring process integrity and safety.

low pressure diaphragm pressure gauges.

Low pressure diaphragm pressure gauges also come in different materials, such as stainless steel, brass, or Monel, to suit varying application requirements. The choice of material is critical, as it influences the gauge's resistance to corrosion, temperature tolerance, and overall durability.

In addition to standard designs, custom-engineered diaphragm pressure gauges are available for specific applications. These tailored solutions can incorporate features like remote seals, digital displays, or special connections to meet unique process demands.

Despite their complexity, low pressure diaphragm gauges require minimal maintenance, adding to their cost-effectiveness. Regular calibration and inspection are necessary to ensure continued accuracy and prevent potential failures.

In conclusion, low pressure diaphragm pressure gauges are vital instruments in industries that rely on precise pressure measurement. Their sensitivity, contamination resistance, and adaptability make them an ideal choice for monitoring delicate processes where small pressure changes can have significant consequences. As technology advances, we can expect further improvements in their design and functionality, enhancing their role in ensuring process integrity and safety.

The diaphragm acts as a, preventing process fluids from coming into contact with the gauge's internal components, thus prolonging the instrument's lifespan and ensuring reliability in corrosive or hazardous environments The diaphragm acts as a, preventing process fluids from coming into contact with the gauge's internal components, thus prolonging the instrument's lifespan and ensuring reliability in corrosive or hazardous environments

The diaphragm acts as a, preventing process fluids from coming into contact with the gauge's internal components, thus prolonging the instrument's lifespan and ensuring reliability in corrosive or hazardous environments The diaphragm acts as a, preventing process fluids from coming into contact with the gauge's internal components, thus prolonging the instrument's lifespan and ensuring reliability in corrosive or hazardous environments low pressure diaphragm pressure gauges.

Low pressure diaphragm pressure gauges also come in different materials, such as stainless steel, brass, or Monel, to suit varying application requirements. The choice of material is critical, as it influences the gauge's resistance to corrosion, temperature tolerance, and overall durability.

In addition to standard designs, custom-engineered diaphragm pressure gauges are available for specific applications. These tailored solutions can incorporate features like remote seals, digital displays, or special connections to meet unique process demands.

Despite their complexity, low pressure diaphragm gauges require minimal maintenance, adding to their cost-effectiveness. Regular calibration and inspection are necessary to ensure continued accuracy and prevent potential failures.

In conclusion, low pressure diaphragm pressure gauges are vital instruments in industries that rely on precise pressure measurement. Their sensitivity, contamination resistance, and adaptability make them an ideal choice for monitoring delicate processes where small pressure changes can have significant consequences. As technology advances, we can expect further improvements in their design and functionality, enhancing their role in ensuring process integrity and safety.

low pressure diaphragm pressure gauges.

Low pressure diaphragm pressure gauges also come in different materials, such as stainless steel, brass, or Monel, to suit varying application requirements. The choice of material is critical, as it influences the gauge's resistance to corrosion, temperature tolerance, and overall durability.

In addition to standard designs, custom-engineered diaphragm pressure gauges are available for specific applications. These tailored solutions can incorporate features like remote seals, digital displays, or special connections to meet unique process demands.

Despite their complexity, low pressure diaphragm gauges require minimal maintenance, adding to their cost-effectiveness. Regular calibration and inspection are necessary to ensure continued accuracy and prevent potential failures.

In conclusion, low pressure diaphragm pressure gauges are vital instruments in industries that rely on precise pressure measurement. Their sensitivity, contamination resistance, and adaptability make them an ideal choice for monitoring delicate processes where small pressure changes can have significant consequences. As technology advances, we can expect further improvements in their design and functionality, enhancing their role in ensuring process integrity and safety. Share

Latest news

-

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

NewsMay.23,2025

-

Industrial Differential Pressure Gauges Global Supplier & Pricelist

NewsMay.23,2025

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025