11月 . 22, 2024 13:09 Back to list

piston type differential pressure gauge suppliers

Understanding Piston Type Differential Pressure Gauges A Guide for Buyers

In industrial applications where fluid dynamics play a crucial role, accurate measurement of pressure differences is essential. One of the most reliable instruments for this purpose is the piston type differential pressure gauge. This device measures the pressure difference between two points in a fluid system, providing vital information for various processes. As businesses look to enhance their operational efficiency, understanding how to choose the right suppliers for these gauges becomes imperative.

What is a Piston Type Differential Pressure Gauge?

A piston type differential pressure gauge operates based on the mechanical movement of a piston within a chamber. When there is a pressure differential across the gauge, the piston moves in response to this pressure change, enabling the gauge to provide a precise reading. These gauges are known for their durability, accuracy, and ability to function in high-pressure environments, making them suitable for sectors such as oil and gas, water treatment, and chemical processing.

Key Features to Consider

When selecting a piston type differential pressure gauge, there are several features and specifications that buyers should consider

1. Accuracy Different models have varying levels of accuracy, often expressed as a percentage of full scale. It's important to select a gauge that meets the precision requirements of the specific application.

2. Pressure Range The pressure range defines the minimum and maximum pressures that the gauge can measure. Buyers should ensure that the gauge’s range aligns with their operational needs.

3. Material Construction The materials used in the gauge's construction greatly affect its durability and resistance to corrosion. Depending on the fluid being measured, gauges made from stainless steel, brass, or specialized alloys may be more appropriate.

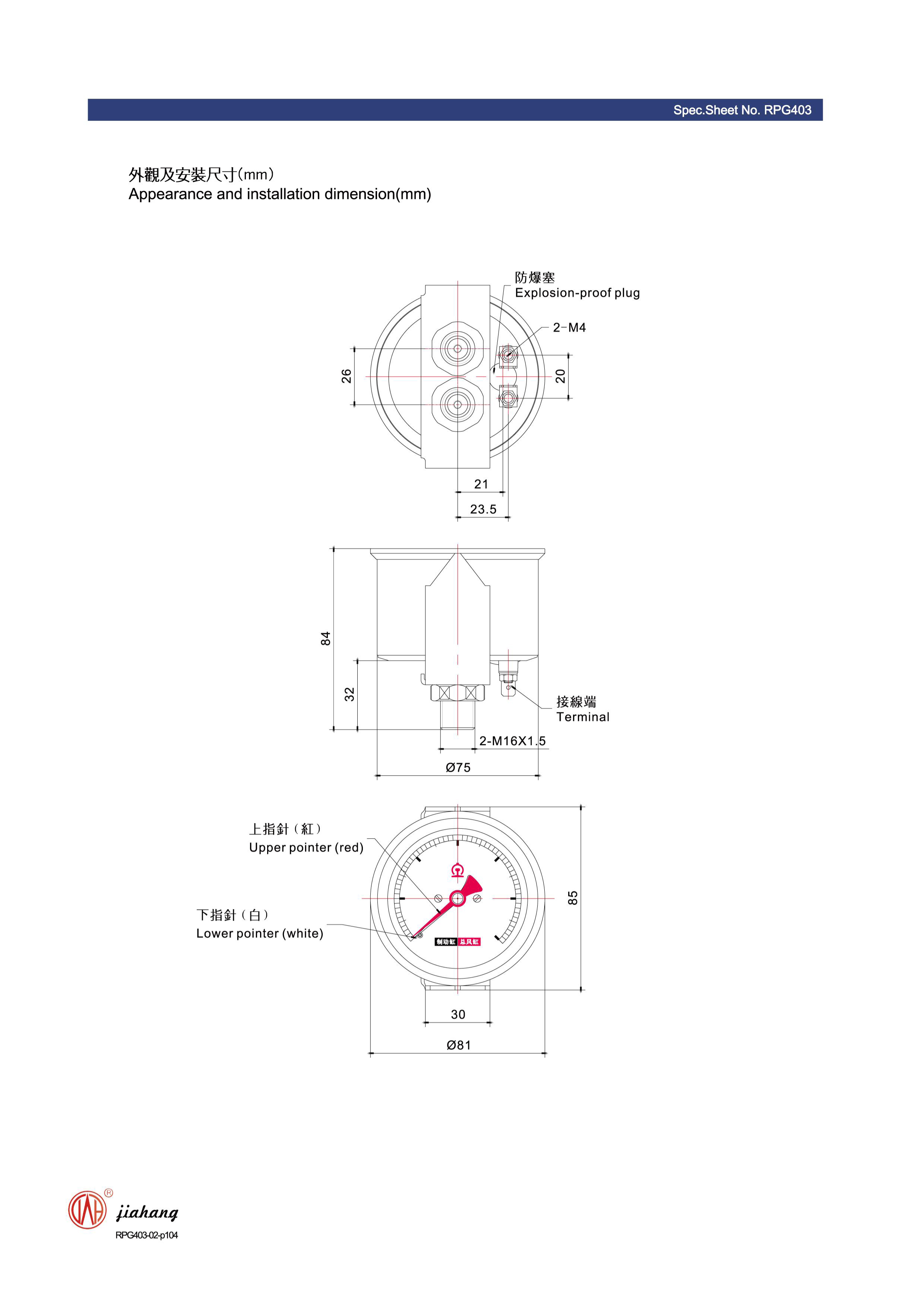

4. Size and Configuration The physical size and layout of the gauge can also influence its installation options. Buyers should consider where the gauge will be installed and what dimensions will fit best within their systems.

piston type differential pressure gauge suppliers

5. Calibration and Maintenance Understanding how to calibrate and maintain the gauge is crucial for long-term performance. Opt for suppliers that provide clear guidelines and support for maintenance.

Choosing the Right Supplier

Finding the right supplier for piston type differential pressure gauges is a crucial step in ensuring optimal performance and reliability of the measurement equipment. Here are some tips for selecting a suitable supplier

1. Reputation and Experience Research potential suppliers to understand their market reputation and years of experience in the industry. Established suppliers often have a proven track record of delivering quality products.

2. Product Range A supplier that offers a wide range of gauges will give you more options and flexibility in choosing the right product for your needs. It's advantageous if they provide customization for specific requirements.

3. Customer Support Quality customer service is essential for addressing any questions or issues that may arise after purchase. Consider suppliers that offer robust technical support and after-sales services.

4. Certifications Check if the supplier’s products are certified by recognized industry standards. This will ensure that the gauges meet certain quality and safety requirements.

5. Pricing and Warranty Evaluate the pricing in relation to the quality of the product. In addition, a good warranty can provide peace of mind regarding the longevity of your investment.

Conclusion

Piston type differential pressure gauges are indispensable tools in various industrial settings. By understanding their features and choosing the right suppliers, businesses can enhance the accuracy and reliability of their pressure measurements. Investing time in research and selection can lead to significant improvements in operational efficiency and safety, ultimately supporting a company’s bottom line. Whether you're a seasoned professional or new to the field, making informed decisions about your differential pressure gauges will have lasting benefits.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025