12月 . 10, 2024 07:22 Back to list

wika differential pressure gauge with switch

Understanding Differential Pressure Gauges with Switches

In industrial applications, the precise measurement of pressure differences between two points is crucial for ensuring operational efficiency and safety. One of the most effective tools for this purpose is the differential pressure gauge with a built-in switch. This article will explore the functionality, applications, and benefits of using such devices in various industries.

What is a Differential Pressure Gauge?

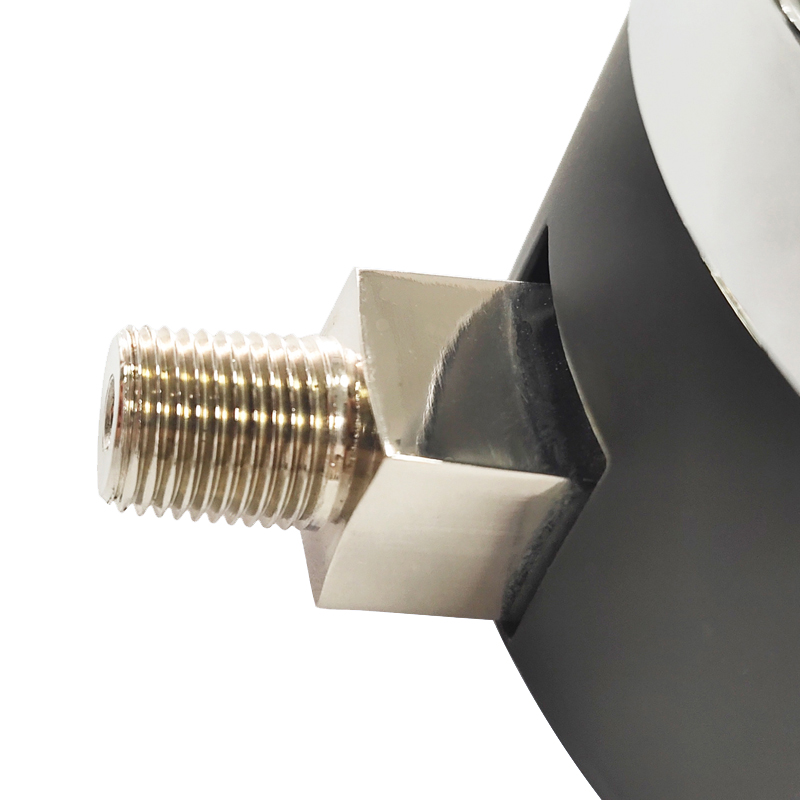

A differential pressure gauge is an instrument that measures the pressure difference between two points in a system. It consists of two pressure inputs, which can sense and report the pressure both upstream and downstream of a component, such as a filter, pump, or valve. The primary function of this gauge is to provide insights into the performance of a system, allowing operators to make informed decisions regarding maintenance and operations.

The Role of the Switch

A differential pressure gauge with a switch combines the pressure measuring capabilities with the functionality of an electrical switch. As the pressure difference reaches a predetermined level, the switch activates or deactivates a circuit, triggering an alarm, shutting down equipment, or initiating other safety measures. This feature enhances the gauge's usability by enabling automatic responses to specific pressure conditions without the need for constant monitoring by operators.

How Does it Work?

The working principle of a differential pressure gauge with a switch is relatively straightforward. The device typically consists of a sensing element (which may be a diaphragm or a capsule) connected to the two pressure inputs. When there is a pressure difference, the sensing element deforms, and this deformation is translated into a reading on the gauge.

The switch component is connected to the gauge's sensing mechanism. When the pressure difference surpasses or falls below a specified threshold, the switch is activated. This activation can control various equipment in the system, effectively serving as a safety measure to prevent potential failures due to excessive pressure differentials.

Applications in Industry

Differential pressure gauges with switches have a myriad of applications across various sectors

wika differential pressure gauge with switch

1. HVAC Systems In heating, ventilation, and air conditioning systems, these gauges monitor air pressure drops across filters. A significant pressure drop indicates that a filter is clogged and needs replacement. The switch can trigger an alarm for maintenance intervention.

2. Oil and Gas In the oil and gas industry, these gauges help monitor the pressure levels in pipelines and process equipment. Excessive differential pressure could signify blockage or failure in the pipelines, prompting immediate attention to prevent hazardous situations.

3. Water Treatment In water treatment plants, differential pressure gauges play an essential role in monitoring sand filters and membranes. A significant change in pressure can indicate fouling, guiding operators on when to initiate backwashing or cleaning processes.

4. Pharmaceutical Manufacturing In cleanroom environments, maintaining specific air pressure differentials is crucial for contamination control. Differential pressure gauges with switches provide real-time monitoring, ensuring that any deviations trigger alerts for immediate corrective action.

Benefits of Differential Pressure Gauges with Switches

1. Safety Improvement The integration of a switch enhances the safety of operations. By automatically triggering alarms or shutdowns, these gauges help prevent catastrophic failures due to excessive pressure differentials.

2. Operational Efficiency Continuous monitoring enables operators to optimize maintenance schedules and operations. Timely alerts can prevent unnecessary downtime and reduce repair costs.

3. Versatile Applications Their adaptability across various industries signifies that differential pressure gauges with switches can be tailored to meet diverse operational needs.

4. User-Friendly Many modern differential pressure gauges come with digital displays and easy installation features, making them user-friendly and accessible even for operators with minimal technical training.

Conclusion

Differential pressure gauges with switches are indispensable tools for many industries, providing critical data on pressure variations essential for operational safety and efficiency. By integrating pressure measurement with automatic switch functionality, these devices not only enhance monitoring capabilities but also enable proactive maintenance strategies. In an era where operational reliability and safety are paramount, understanding and implementing differential pressure gauges is a step towards achieving operational excellence.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025