7월 . 27, 2024 22:23 Back to list

Design and Application of Customized Diaphragm Pressure Sensors for Enhanced Accuracy and Performance

Custom Diaphragm Pressure Elements Precision Measurement Solutions for Diverse Applications

In various industrial and scientific fields, accurate pressure measurement is critical for ensuring safety, efficiency, and reliability. Among the technologies employed for this purpose, custom diaphragm pressure elements have emerged as a versatile solution tailored to meet the specific needs of different applications. These devices utilize a flexible diaphragm as a primary sensing element to convert pressure changes into measurable signals, offering precision and responsiveness.

Understanding Diaphragm Pressure Elements

At its core, a diaphragm pressure element comprises a thin, flexible membrane—typically made from materials such as stainless steel, polymer, or elastomers—that deforms in response to pressure variations. As pressure is applied to one side of the diaphragm, it flexes, creating a mechanical displacement that is then translated into an electrical signal by means of various transduction methods, such as strain gauges, capacitive sensors, or piezoelectric elements.

Diaphragm pressure elements are favored in numerous applications because they can be designed to withstand extreme conditions, including high temperatures, corrosive environments, and significant pressure ranges. Their compact design and reliability make them suitable for measuring gases and liquids in diverse industries, from pharmaceuticals and food processing to oil and gas and aerospace.

Customization for Unique Requirements

One of the most significant advantages of diaphragm pressure elements is the ability to customize them to fit specific requirements. Different applications may necessitate unique dimensions, materials, or configurations. For example, in the food industry, sanitary construction materials are crucial to prevent contamination, while offshore oil applications may require devices that can withstand high pressure and corrosive seawater.

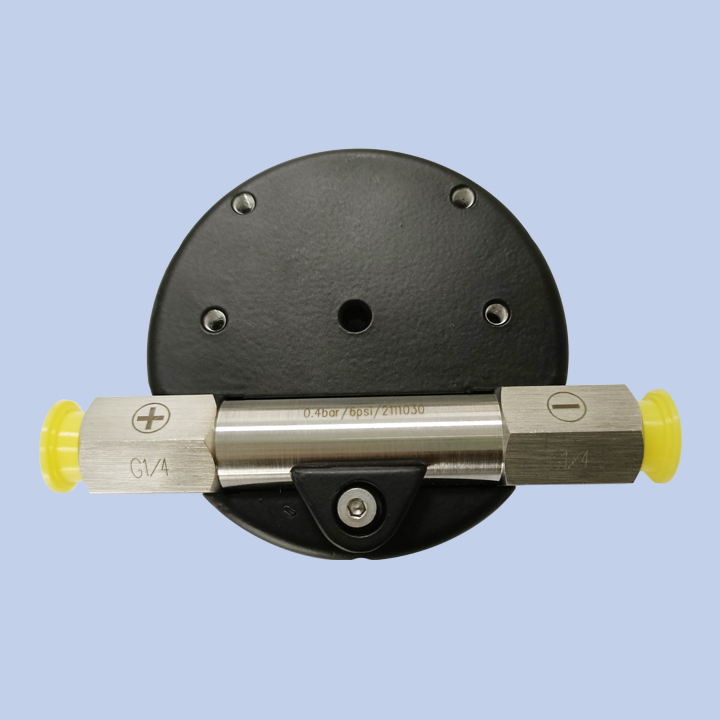

custom diaphragm pressure element

Customization can also extend to electrical interfaces, enabling seamless integration with existing systems. By tailoring the output signals to match industry standards or particular equipment compatibility, manufacturers can ensure that the diaphragm pressure element operates effectively within a broader system architecture.

Moreover, some applications demand enhanced accuracy and zero point stability. Manufacturers of custom diaphragm pressure elements can incorporate advanced sensing technology, such as high-precision strain gauges or temperature compensation, to meet these stringent performance criteria.

Applications Across Industries

The versatility of custom diaphragm pressure elements leads to their adoption across various sectors. In the oil and gas industry, these sensors are vital for monitoring pressure in pipelines and storage tanks, helping to detect leaks or overpressurization that could lead to catastrophic failures. In medical devices, diaphragm pressure sensors are employed in ventilators and infusion pumps, where maintaining precise pressure is essential for patient safety.

Moreover, in the environmental sector, these sensors are utilized for monitoring atmospheric pressure, water levels, and even industrial emissions. Their robust design allows them to perform well in harsh outdoor conditions, providing reliable data for environmental monitoring and management.

Conclusion

Custom diaphragm pressure elements are indispensable components in the realm of pressure measurement, offering both versatility and precision across a range of industries. As technology continues to evolve and industries demand higher standards of accuracy and reliability, the customization of diaphragm pressure elements will play a crucial role in shaping the future of pressure sensing. By leveraging advanced materials and technologies, manufacturers can deliver solutions that not only meet but exceed industry requirements, ensuring safety and efficiency in critical applications. Whether in a laboratory, a manufacturing facility, or an offshore platform, custom diaphragm pressure elements stand as a testament to the importance of precision in modern engineering and technology.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025