7월 . 01, 2024 01:50 Back to list

Diaphragm and Capsule Pressure Gauges Maintenance and Service Essentials

Understanding Diaphragm and Capsule Pressure Gauges Their Service and Importance

Pressure gauges play a crucial role in various industries, from manufacturing to engineering, by providing essential information about the pressure levels within a system. Two common types of pressure measurement devices are diaphragm and capsule pressure gauges. These instruments are designed to withstand different conditions and offer accurate readings, making them indispensable in numerous applications.

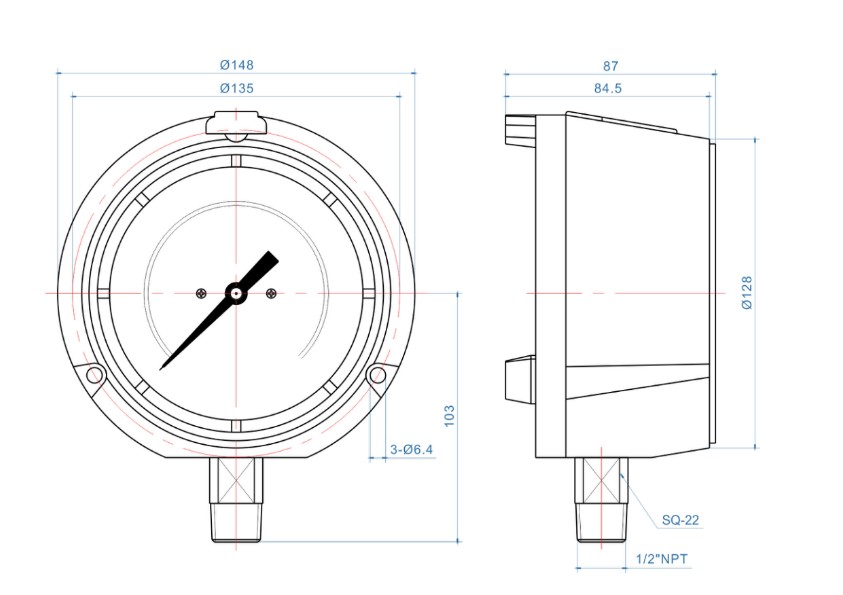

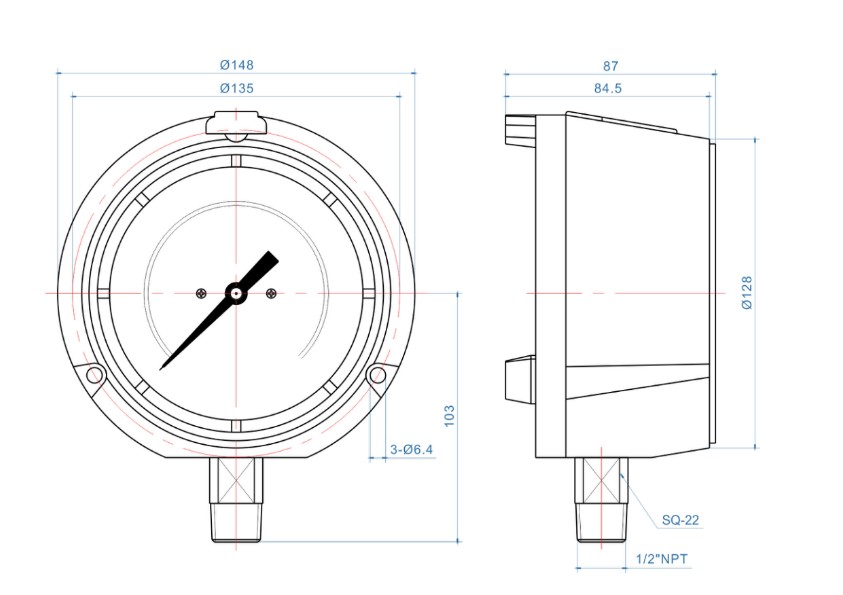

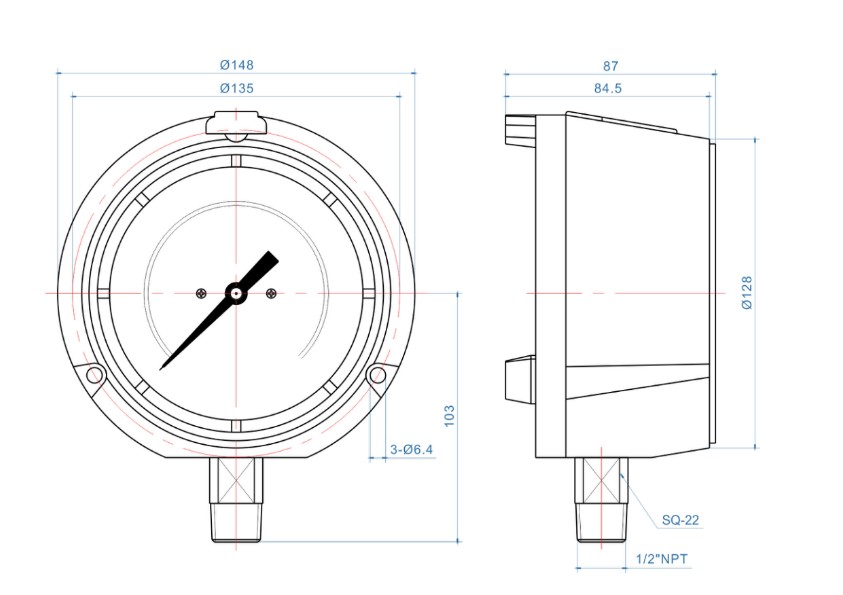

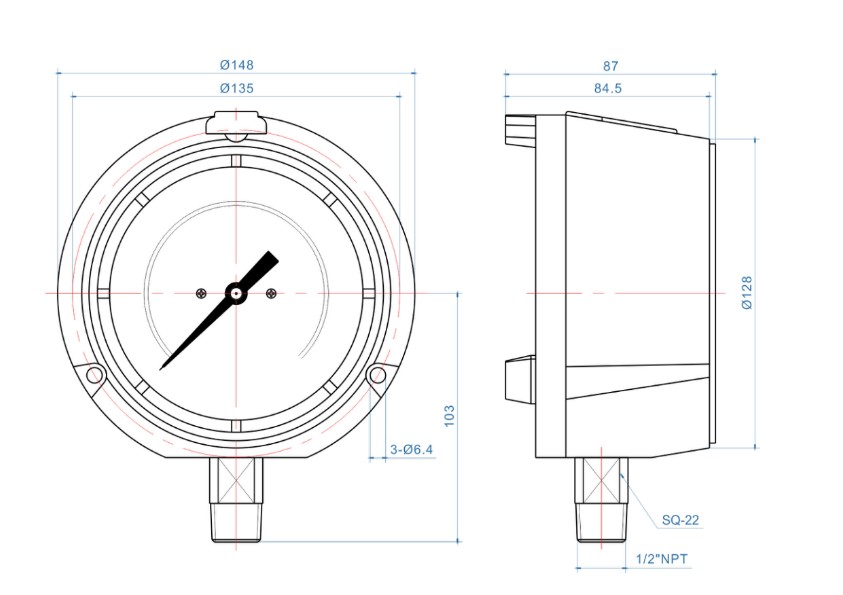

A diaphragm pressure gauge operates on the principle of a flexible diaphragm that deforms under the influence of pressure. The diaphragm, usually made of stainless steel or other durable materials, separates the process fluid from the measuring mechanism. When pressure is applied, the diaphragm deflects, and this movement is translated into a mechanical indication of the pressure. These gauges are ideal for low-pressure applications, such as in the chemical and pharmaceutical industries, where precision and protection against contamination are paramount. Regular service and maintenance, including calibration, ensure the continued accuracy and reliability of diaphragm pressure gauges.

On the other hand, capsule pressure gauges combine aspects of both diaphragm and Bourdon tube gauges. They consist of two diaphragms sealed together, creating a 'capsule' that houses a filling fluid. Pressure acting on one side of the capsule causes it to bend, transmitting the force to the mechanical indicator. Capsule gauges are well-suited for moderate pressure applications and environments with aggressive media due to their robust construction Capsule gauges are well-suited for moderate pressure applications and environments with aggressive media due to their robust construction Capsule gauges are well-suited for moderate pressure applications and environments with aggressive media due to their robust construction Capsule gauges are well-suited for moderate pressure applications and environments with aggressive media due to their robust construction

Capsule gauges are well-suited for moderate pressure applications and environments with aggressive media due to their robust construction Capsule gauges are well-suited for moderate pressure applications and environments with aggressive media due to their robust construction diaphragm and capsule pressure gauges service. Like diaphragm gauges, regular servicing, including cleaning and checking for leaks, is crucial for optimal performance.

Both diaphragm and capsule pressure gauges serve as vital safety tools, preventing over-pressurization and ensuring system integrity. Their selection depends on factors such as the operating pressure, process media, environmental conditions, and the level of accuracy required. A professional understanding of these gauges and their service requirements is essential for efficient system operation and safety.

In conclusion, diaphragm and capsule pressure gauges are integral components in numerous industrial processes. Their ability to provide accurate pressure readings under diverse conditions is invaluable. However, their proper service and maintenance cannot be overstated. Regular checks, timely repairs, and calibration are necessary to maintain their accuracy and extend their operational lifespan. By doing so, businesses can minimize downtime, enhance productivity, and ensure compliance with safety regulations. The importance of diaphragm and capsule pressure gauges, along with their dedicated service, underscores the significance of investing in quality measurement technology.

diaphragm and capsule pressure gauges service. Like diaphragm gauges, regular servicing, including cleaning and checking for leaks, is crucial for optimal performance.

Both diaphragm and capsule pressure gauges serve as vital safety tools, preventing over-pressurization and ensuring system integrity. Their selection depends on factors such as the operating pressure, process media, environmental conditions, and the level of accuracy required. A professional understanding of these gauges and their service requirements is essential for efficient system operation and safety.

In conclusion, diaphragm and capsule pressure gauges are integral components in numerous industrial processes. Their ability to provide accurate pressure readings under diverse conditions is invaluable. However, their proper service and maintenance cannot be overstated. Regular checks, timely repairs, and calibration are necessary to maintain their accuracy and extend their operational lifespan. By doing so, businesses can minimize downtime, enhance productivity, and ensure compliance with safety regulations. The importance of diaphragm and capsule pressure gauges, along with their dedicated service, underscores the significance of investing in quality measurement technology.

Capsule gauges are well-suited for moderate pressure applications and environments with aggressive media due to their robust construction Capsule gauges are well-suited for moderate pressure applications and environments with aggressive media due to their robust construction

Capsule gauges are well-suited for moderate pressure applications and environments with aggressive media due to their robust construction Capsule gauges are well-suited for moderate pressure applications and environments with aggressive media due to their robust construction diaphragm and capsule pressure gauges service. Like diaphragm gauges, regular servicing, including cleaning and checking for leaks, is crucial for optimal performance.

Both diaphragm and capsule pressure gauges serve as vital safety tools, preventing over-pressurization and ensuring system integrity. Their selection depends on factors such as the operating pressure, process media, environmental conditions, and the level of accuracy required. A professional understanding of these gauges and their service requirements is essential for efficient system operation and safety.

In conclusion, diaphragm and capsule pressure gauges are integral components in numerous industrial processes. Their ability to provide accurate pressure readings under diverse conditions is invaluable. However, their proper service and maintenance cannot be overstated. Regular checks, timely repairs, and calibration are necessary to maintain their accuracy and extend their operational lifespan. By doing so, businesses can minimize downtime, enhance productivity, and ensure compliance with safety regulations. The importance of diaphragm and capsule pressure gauges, along with their dedicated service, underscores the significance of investing in quality measurement technology.

diaphragm and capsule pressure gauges service. Like diaphragm gauges, regular servicing, including cleaning and checking for leaks, is crucial for optimal performance.

Both diaphragm and capsule pressure gauges serve as vital safety tools, preventing over-pressurization and ensuring system integrity. Their selection depends on factors such as the operating pressure, process media, environmental conditions, and the level of accuracy required. A professional understanding of these gauges and their service requirements is essential for efficient system operation and safety.

In conclusion, diaphragm and capsule pressure gauges are integral components in numerous industrial processes. Their ability to provide accurate pressure readings under diverse conditions is invaluable. However, their proper service and maintenance cannot be overstated. Regular checks, timely repairs, and calibration are necessary to maintain their accuracy and extend their operational lifespan. By doing so, businesses can minimize downtime, enhance productivity, and ensure compliance with safety regulations. The importance of diaphragm and capsule pressure gauges, along with their dedicated service, underscores the significance of investing in quality measurement technology. Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025