10월 . 11, 2024 14:34 Back to list

diaphragm pressure sensing element exporters

Diaphragm Pressure Sensing Elements An Overview of Exporters

Diaphragm pressure sensing elements are critical components in various industrial applications, including process control, HVAC systems, and automotive industries. These sensors are designed to measure pressure and transmit that information into usable data for monitoring and control systems. As the demand for precision and reliability in pressure measurement rises across global markets, the role of exporters specializing in diaphragm pressure sensing elements becomes increasingly significant.

What are Diaphragm Pressure Sensing Elements?

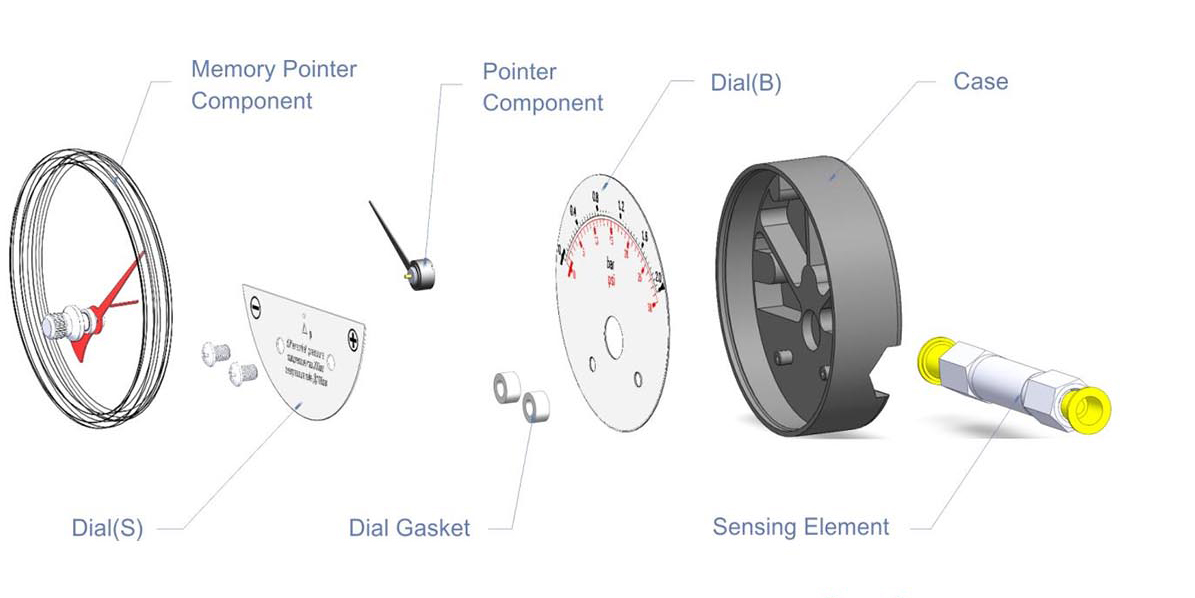

At their core, diaphragm pressure sensing elements consist of a flexible membrane (the diaphragm) that deflects in response to pressure changes. This deflection is then converted into an electrical signal. The accuracy of these sensors is vital for operations in fields such as oil and gas, pharmaceuticals, and water treatment, where precise pressure measurements can prevent hazards and enhance efficiency.

Key Features of Diaphragm Pressure Sensors

1. High Accuracy Diaphragm sensors are known for their ability to deliver high levels of accuracy in pressure measurement. This is essential in applications where slight fluctuations in pressure can lead to significant consequences. 2. Wide Range of Pressure Measurement These sensors can measure both high and low pressures, making them versatile for different types of applications. 3. Compatibility with Various Fluids Diaphragm pressure sensing elements can be designed to withstand corrosive environments, allowing them to be used with a variety of gases and liquids without compromising their integrity.

4. Compact Design Their relatively small size enables easy integration into systems where space is constrained, providing flexibility in design.

The Role of Exporters in the Market

Exporters of diaphragm pressure sensing elements often play a crucial role in the supply chain, facilitating the availability of technology across borders. They connect manufacturers with industries that require these essential components. Here are several key aspects of their role

1. Diverse Supply Sources Exporters often source diaphragm pressure sensing elements from a range of manufacturers, ensuring a wide variety of products that can meet specific client needs. This diversity allows clients to select sensors based on their unique operational specifications and regulatory requirements.

diaphragm pressure sensing element exporters

2. Market Expansion By exporting diaphragm pressure sensing elements to international markets, these companies help manufacturers expand their reach. As industries across the globe continue to modernize their operations, the demand for reliable pressure sensing elements grows, creating opportunities for exporters.

3. Knowledge and Support Experienced exporters provide not only products but also technical support and insights into the best applications for various diaphragm pressure sensors. This guidance can aid companies in selecting the appropriate sensors that align with their process requirements.

4. Quality Assurance Many established exporters conduct rigorous quality checks and certifications to ensure that the diaphragm pressure sensing elements meet international standards. This commitment to quality is essential in sectors where safety and accuracy are paramount.

Challenges Faced by Exporters

Despite the opportunities present in the diaphragm pressure sensing elements market, exporters also face several challenges

1. Regulatory Compliance Different countries have varying regulations concerning the import and export of industrial components. Navigating these regulations can be complex and requires expertise.

2. Supply Chain Disruptions Global events, such as pandemics or trade disputes, can disrupt supply chains and impact the availability of products, leading to potential delays in delivery.

3. Technological Advancements Keeping pace with rapidly changing technologies in pressure sensing can be challenging. Exporters must continuously update their offerings to include the latest advancements.

Conclusion

Diaphragm pressure sensing elements are indispensable in many industries, and exporters play a fundamental role in delivering these critical components to the market. Their ability to connect manufacturers with global demand, ensure quality, and provide valuable insights makes them key players in the expansion and innovation of pressure measurement technology. As industries continue to advance and require more sophisticated solutions, the influence of exporters in this field will undoubtedly grow, presenting both opportunities and challenges that need to be navigated carefully.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025