11월 . 09, 2024 08:56 Back to list

Innovative Capacitive Diaphragm Pressure Sensors for Enhanced Measurement Accuracy and Reliability

The Jah Capacitance Diaphragm Pressure Gauge An Overview

Pressure measurement is a critical aspect of various industrial applications, ranging from process control to environmental monitoring. Among the many types of pressure gauges available, the Jah capacitance diaphragm pressure gauge stands out due to its precision, reliability, and ability to function in a variety of challenging environments. This article will delve into the working principles, advantages, applications, and potential considerations when using this innovative measurement device.

Working Principles

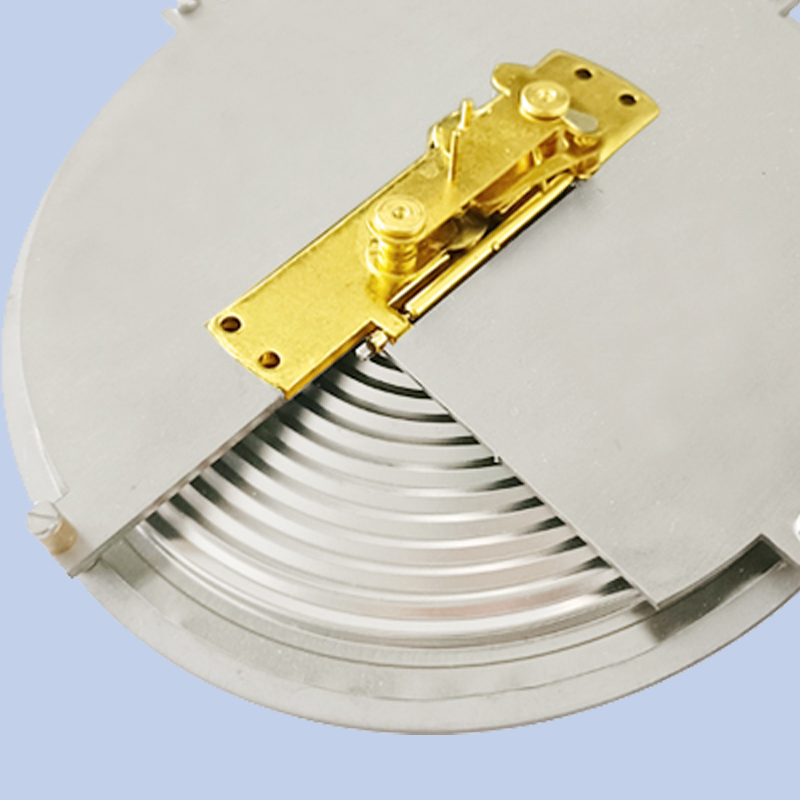

At the heart of the Jah capacitance diaphragm pressure gauge is a flexible diaphragm that responds to changes in pressure. When pressure is applied, the diaphragm deflects, altering the capacitance of a sensor situated behind it. This change in capacitance is directly proportional to the pressure applied, enabling accurate and instantaneous pressure readings. The gauge’s electronic circuitry processes these capacitance changes to display the pressure on an easily readable digital interface or transmit it to a monitoring system.

The design of the diaphragm allows it to be sensitive enough to detect even the slightest pressure variations while maintaining robustness against environmental factors. The materials used for the diaphragm, typically stainless steel or other high-strength alloys, are chosen for their durability and resistance to corrosive substances, ensuring longevity in various applications.

Advantages

One of the primary advantages of the Jah capacitance diaphragm pressure gauge is its high accuracy. With a tolerance of as little as 0.1% of full scale, it is suitable for applications that require precise measurements. Additionally, these gauges offer excellent stability over time, minimizing the need for frequent recalibration.

Another benefit is the gauge’s ability to measure both absolute and differential pressures. This versatility makes it suitable for a wide range of industrial processes, from simple mechanical systems to complex scientific experiments.

Moreover, the capacitance measurement principle allows for a rapid response time

. In dynamic pressure applications, where conditions can change swiftly, the Jah gauge ensures prompt readings, enhancing operational efficiency.jah capacitance diaphragm pressure gauge

Applications

The Jah capacitance diaphragm pressure gauge finds extensive use across various industries. In the oil and gas sector, for example, it is employed in pipeline monitoring and control systems to ensure safe and efficient operations. Its robust design allows it to function in high-pressure environments, while its precision ensures compliance with regulatory standards.

In the pharmaceutical and food industries, where hygiene is paramount, these gauges can be used to monitor pressure in sterilization and processing equipment. The materials used in their construction can often be made to meet sanitary standards, making them ideal for sensitive applications.

Furthermore, in the realm of environmental science, these gauges play a crucial role in monitoring atmospheric pressure and other environmental parameters, contributing to weather forecasting and climate research.

Considerations

While the Jah capacitance diaphragm pressure gauge offers numerous advantages, users should consider certain factors. The gauge’s sensitivity to pressure changes means that it can be susceptible to shock and vibration, which may affect its accuracy. Therefore, careful installation and possibly additional protective measures may be required in very dynamic environments.

Additionally, the cost of these gauges can be higher than that of traditional mechanical gauges. However, given their accuracy and reliability, many industries find the investment worthwhile.

Conclusion

The Jah capacitance diaphragm pressure gauge represents an advanced solution for precise pressure measurement across various applications. Its innovative design, combined with high accuracy and rapid response capabilities, makes it a preferred choice in many industries. By understanding its working principles, advantages, and proper installation considerations, users can fully leverage the capabilities of this cutting-edge device to enhance their operational efficiencies and ensure safety in their processes. As technology continues to progress, it is likely that such gauges will become even more integral to modern industrial practices, paving the way for increased automation and data-driven decision-making.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025