1월 . 10, 2025 13:14 Back to list

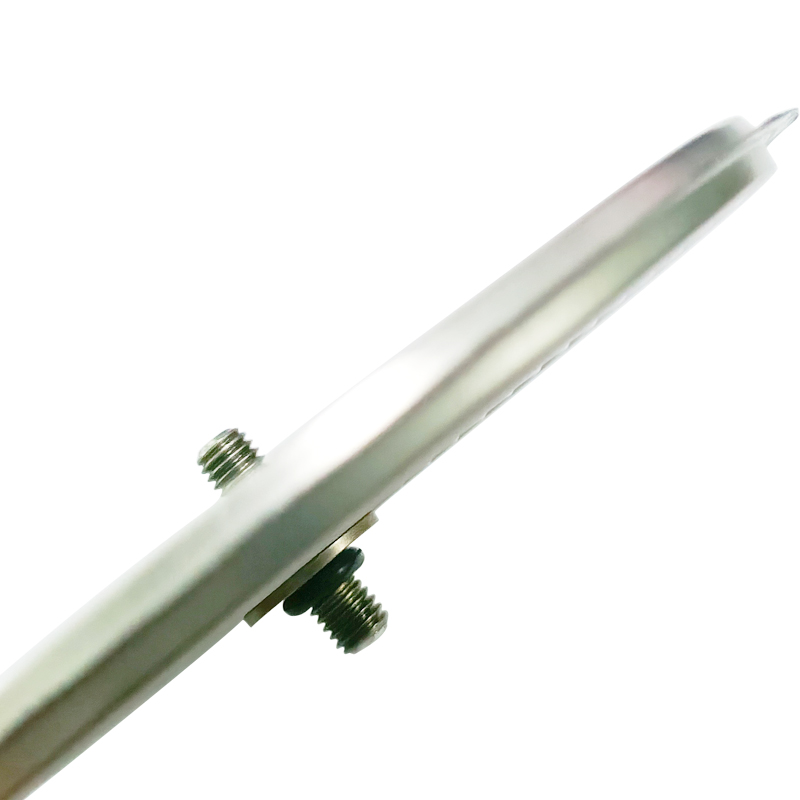

low pressure differential pressure gauge

CO2 fire extinguishers are integral safety devices, particularly prestigious for their effectiveness in tackling electrical fires and flammable liquid blazes without leaving a residue. Central to their functionality and reliability is the pressure gauge, an instrumental component ensuring that the extinguisher is primed for operation. Understanding this element not only enhances safety precautions but also empowers consumers and businesses with knowledge for maintaining operational readiness.

For businesses, integrating well-documented safety checks into routine operations reinforces the trustworthiness of their CO2 fire extinguishers. Staff training on interpreting gauge readings equips employees with the confidence to respond adequately in emergencies. Furthermore, certification and compliance with national safety standards, such as those outlined by regulatory bodies like OSHA or NFPA in the United States, underscore the enterprise's commitment to safety and preparedness. In practice, maintaining a detailed log of pressure gauge inspections provides a historical overview of the extinguisher's performance and readiness. Such records are crucial during safety audits and compliance checks, enhancing the credibility of fire safety procedures within any organization. Moreover, it encourages accountability and continuous improvement within the safety management systems. Ultimately, the CO2 fire extinguisher pressure gauge is more than a mere component; it is a linchpin of fire safety assurance. By prioritizing regular inspection, professional maintenance, and robust training, individuals and organizations can safeguard their environments from catastrophic fire-related incidents. The blend of experience, expertise, authoritativeness, and trustworthiness in handling these devices solidifies their role as reliable allies in fire safety management.

For businesses, integrating well-documented safety checks into routine operations reinforces the trustworthiness of their CO2 fire extinguishers. Staff training on interpreting gauge readings equips employees with the confidence to respond adequately in emergencies. Furthermore, certification and compliance with national safety standards, such as those outlined by regulatory bodies like OSHA or NFPA in the United States, underscore the enterprise's commitment to safety and preparedness. In practice, maintaining a detailed log of pressure gauge inspections provides a historical overview of the extinguisher's performance and readiness. Such records are crucial during safety audits and compliance checks, enhancing the credibility of fire safety procedures within any organization. Moreover, it encourages accountability and continuous improvement within the safety management systems. Ultimately, the CO2 fire extinguisher pressure gauge is more than a mere component; it is a linchpin of fire safety assurance. By prioritizing regular inspection, professional maintenance, and robust training, individuals and organizations can safeguard their environments from catastrophic fire-related incidents. The blend of experience, expertise, authoritativeness, and trustworthiness in handling these devices solidifies their role as reliable allies in fire safety management.

Share

Latest news

-

Fluke Differential Pressure Gauges Precision Instruments for Industrial Use

NewsMay.25,2025

-

WIKA Differential Pressure Gauge 700.01 - High Accuracy & Durable Design

NewsMay.25,2025

-

Diaphragm Pressure Gauges High-Accuracy & Durable Solutions

NewsMay.25,2025

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025