7월 . 27, 2024 22:20 Back to list

OEM Differential Pressure Gauge with Alarm Function for Enhanced Monitoring and Detection Systems

Understanding OEM Differential Pressure Gauges with Tattletale Functionality

In various industrial applications, the need for precise measurement and monitoring of differential pressure is crucial for maintaining optimal performance and ensuring safety. One of the innovations that have emerged in this field is the OEM (Original Equipment Manufacturer) differential pressure gauge equipped with a Tattletale feature. This article will explore the significance, operation, and benefits of these advanced gauges.

What is a Differential Pressure Gauge?

A differential pressure gauge is an instrument used to measure the difference in pressure between two points in a system. This measurement is essential in numerous applications, including HVAC systems, filtration processes, and various manufacturing operations. By monitoring differential pressure, operators can gain insights into the efficiency of equipment, detect blockages, and ensure safe operation.

The Role of OEM Differential Pressure Gauges

OEM differential pressure gauges are tailored to specific applications and designed to meet the unique requirements of various industrial sectors. These gauges provide accurate and reliable readings, which are essential for process control and monitoring. The OEM aspect signifies that these gauges are produced by a manufacturer who specializes in the particular needs of the industry, ensuring compatibility and efficiency.

What is a Tattletale Feature?

The Tattletale feature in a differential pressure gauge serves as an alert system for operators

. It helps in identifying abnormal conditions in the system by providing visible or audible alarms when predetermined pressure thresholds are exceeded. The term Tattletale implies that the gauge 'tattles' or informs the user about any significant changes that could indicate a problem, such as equipment malfunctions or potential safety hazards.How Tattletale Functionality Works

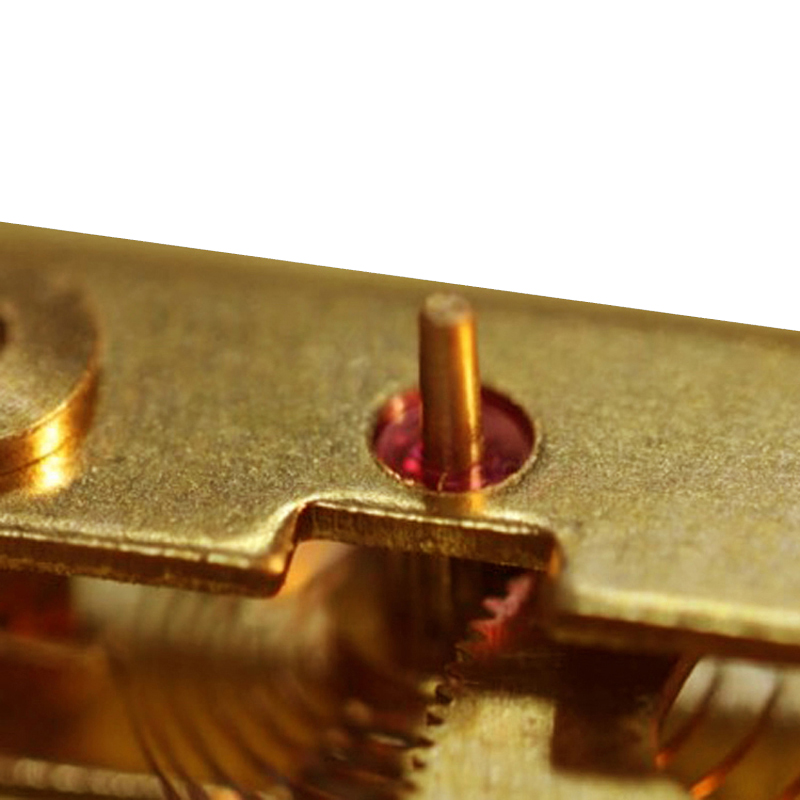

oem differential pressure gauge with tattletale

Typically, the Tattletale feature integrates with the differential pressure gauge's electronic or mechanical components. It may include visual indicators like LED lights or acoustic signals that activate when the differential pressure exceeds or falls below specific limits. This proactive monitoring capability allows operators to react quickly to issues, minimizing the risk of system failures and costly downtime.

Benefits of Using OEM Differential Pressure Gauges with Tattletale

1. Enhanced Safety The Tattletale feature significantly improves safety by providing immediate alerts to potentially hazardous situations, allowing for quick intervention and risk mitigation.

2. Preventive Maintenance By monitoring changes in differential pressure, operators can identify trends or anomalies early, facilitating preventive maintenance, reducing the likelihood of unexpected failures, and extending equipment lifespan.

3. Improved Efficiency Accurate differential pressure readings enable better control of processes, leading to improved operational efficiency. Knowing when to clean filters or service equipment can optimize performance.

4. Customization OEM gauges can be customized to fit specific operational requirements, including size, measurement range, and material, ensuring they meet the needs of various applications effectively.

5. Data Logging and Integration Many modern differential pressure gauges with Tattletale functionality come equipped with data logging capabilities. This allows for long-term trend analysis, integration with other monitoring systems, and comprehensive reporting features.

Conclusion

In conclusion, OEM differential pressure gauges with Tattletale functionality represent a significant advancement in industrial monitoring and safety. They offer critical insights into operational efficiency while providing immediate notifications of potential issues. For industries reliant on precise measurements, adopting these sophisticated gauges can lead to enhanced safety, improved efficiency, and overall operational excellence. As technology continues to evolve, the integration of smart features in pressure measurement tools will undoubtedly shape the future of industrial applications.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025